Gluing machine

A glue machine and rubber hose technology, which is applied in the field of glue machines, can solve the problems of insufficient sealability, inability to guarantee stability, waste of glue, etc., and achieve the effects of easy promotion, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

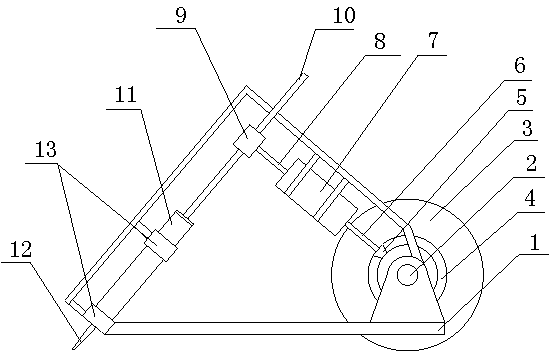

[0011] like figure 1 The shown glue machine includes a bracket 1, a motor 7 and a roller 3. The bracket 1 hinges the roller 3 through the wheel shaft 2. The wheel shaft 2 is connected to the large gear 4. The large gear 4 meshes with the pinion 5, and the pinion 5 passes through the moving shaft 6. Connect the motor 7, the motor 7 is connected to the pusher 9 through the push shaft 8, the pusher 9 is connected to the push rod 10, the push rod 10 is connected to the top of the rubber hose 11, the bottom of the rubber hose 11 is connected to the glue nozzle 12, and the rubber hose 12 is connected to the frame through the fixing frame 13 1. The motor 7 is a low-voltage and low-speed motor. The surface of the roller 3 is rough, the structure is simple, it is easy to use, and it has a wide range of applications. The pusher is used to squeeze the glue, which ensures the stability of the glue output, high work efficiency, and is easy to promote.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com