Laser tunnel furnace light beam micro-integration focusing method and device

A focusing method and laser beam technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of high cost, complicated fixtures, hindering the popularization and application of laser heating technology, etc., and achieve the effect of solving energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

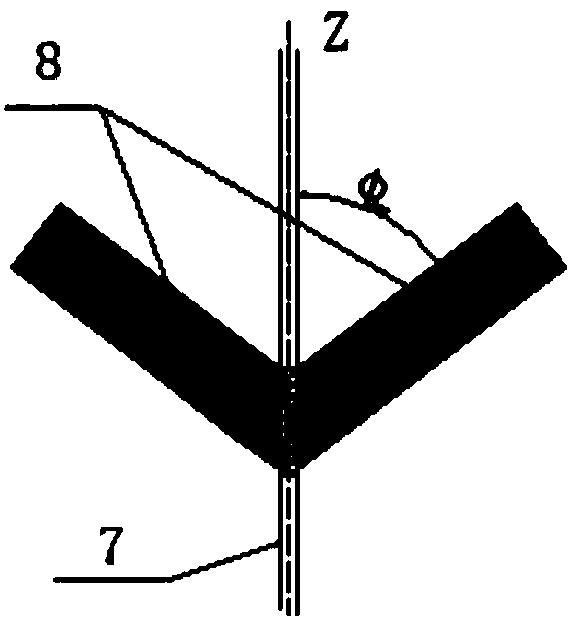

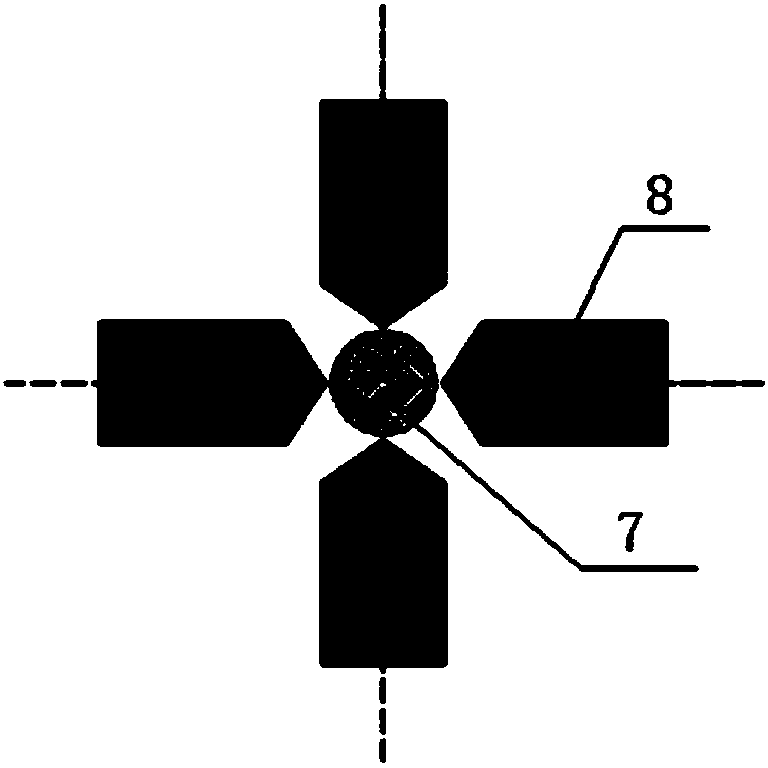

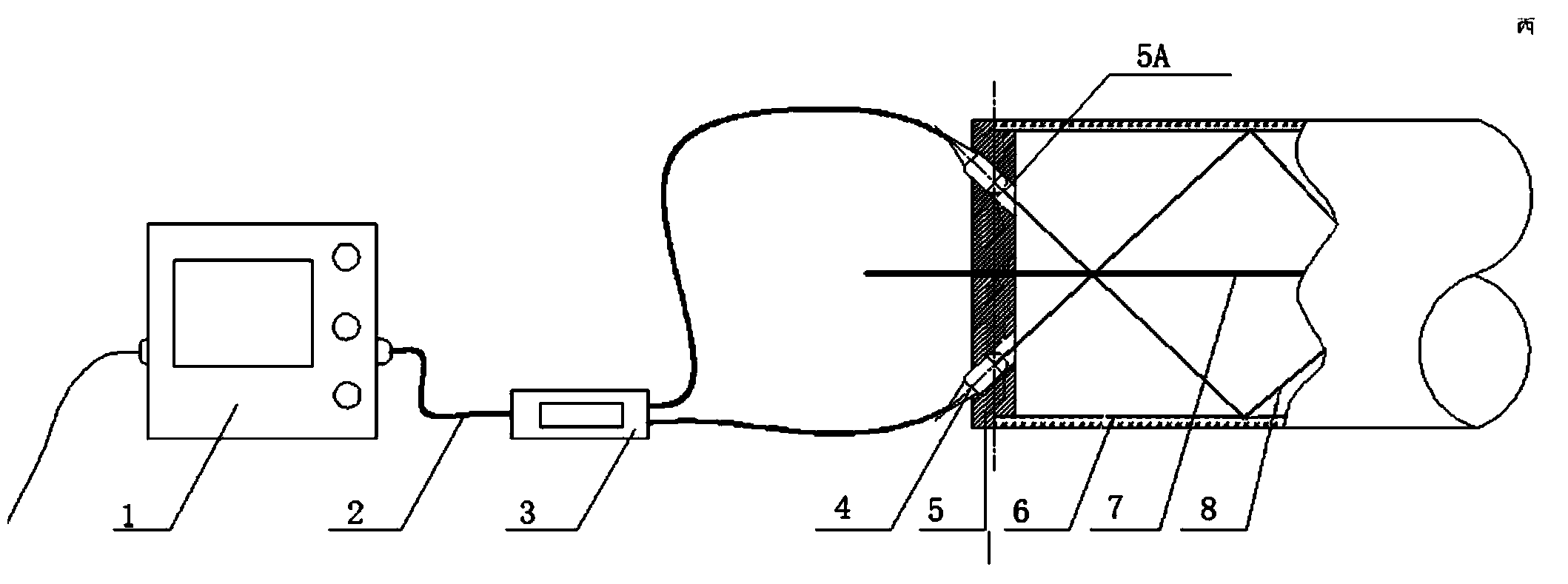

[0014] Laser tunnel furnace beam calculus focusing method and device of the present invention, the device is as image 3 As shown, the device includes a high-power laser transmitter 1 , an optical fiber 2 , a multi-channel splitter 3 , and a laser beam emitting head 4 and a bracket 5 . The high-power laser transmitter 1 is connected with a multi-beam optical path distributor 3 through an optical fiber 2, and the one-many optical path distributor 3 divides a beam of light into multiple beams of light (such as figure 2 As shown), to realize the differentiation of the light beam, multiple beams of light lead the light to the laser emitting head 4 through the optical fiber, the laser beam emitting head 4 is fixed on the bracket 5, and the mounting holes 5A on the bracket 5 are evenly distributed, see Figure 4 As shown, the bracket 5 can be made of metal or high-performance plastic, and the temperature in the laser tunnel furnace 6 is only high on the carbon fiber irradiated by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com