Method for fireproof isolation welding in oil and gas pipeline hot work

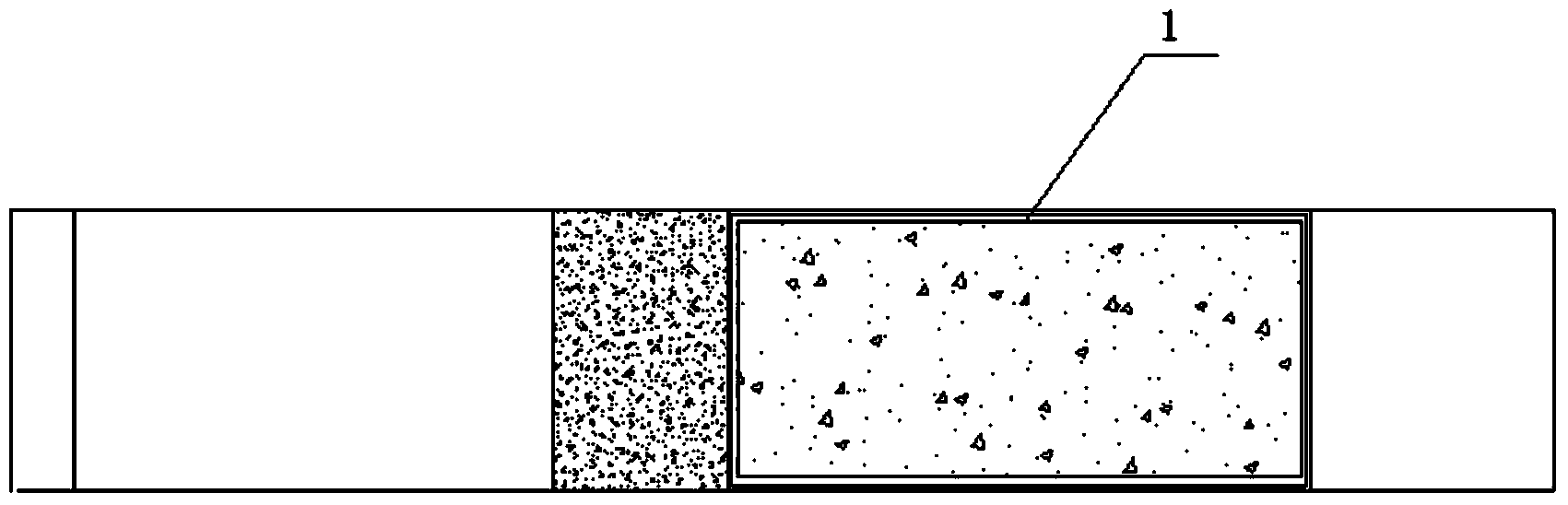

A technology for hot work and oil and gas pipelines, applied to pipeline systems, welding equipment, hollow objects, etc., can solve problems such as poor fire prevention effect of oil and gas leakage, unstable butter wall, etc., and achieve the effect of low use cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Perform pressure relief and oil discharge on oil and gas pipelines. If the pipeline does not have the conditions for pressure relief and oil discharge, seal the pipeline under pressure to ensure that the pipeline that needs to be equipped with a fireproof wall is free of oil and pressure;

[0040] Step 2: Measure the industrial salt and butter, and weigh them according to the mass percentage, the industrial salt is 40%, the butter is 60%, mix and stir the two, so that the industrial salt and butter are evenly mixed;

[0041] Step 3:

[0042] Step 3.1: Add water to the obtained industrial salt and stir to make the industrial salt moist;

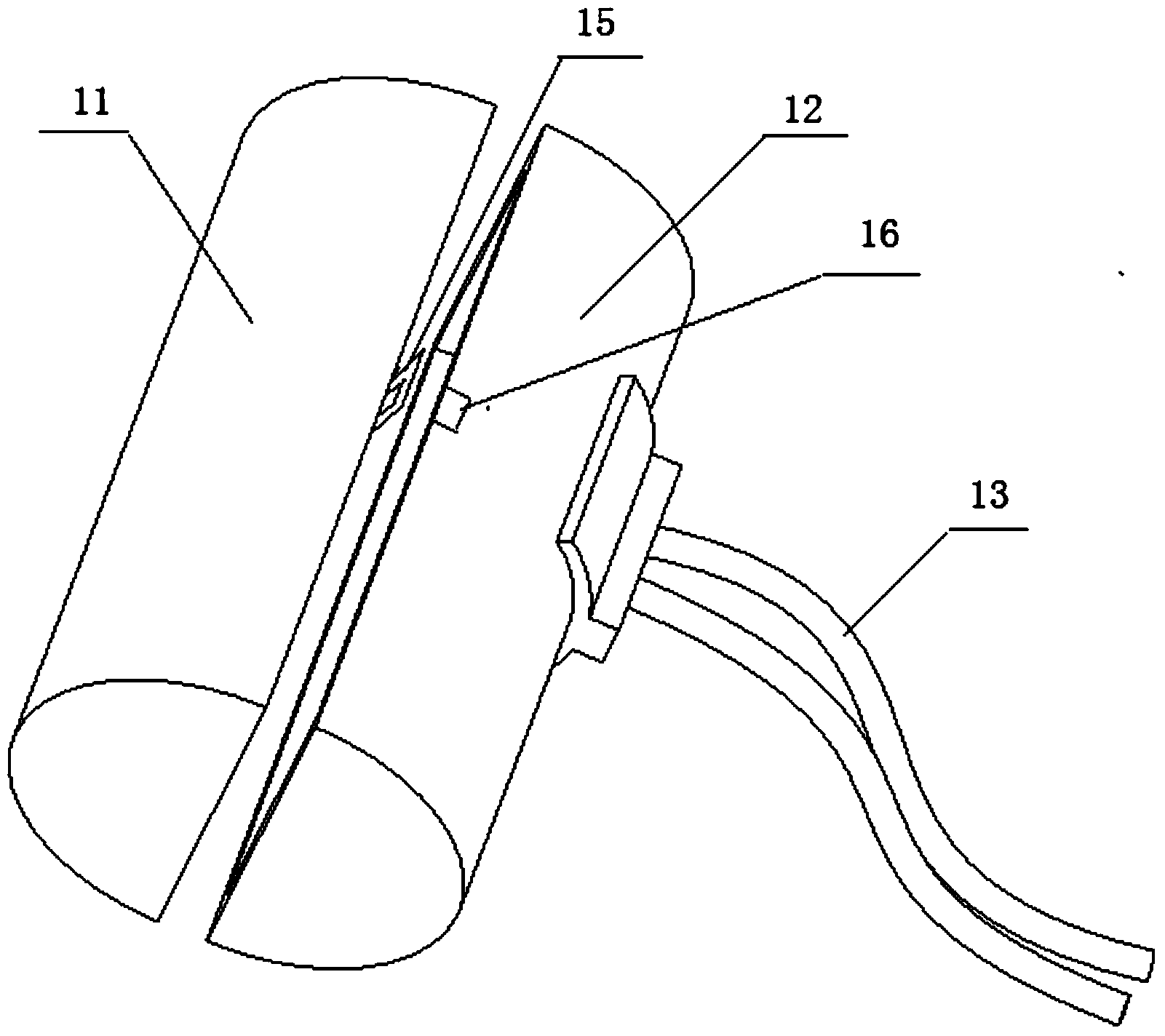

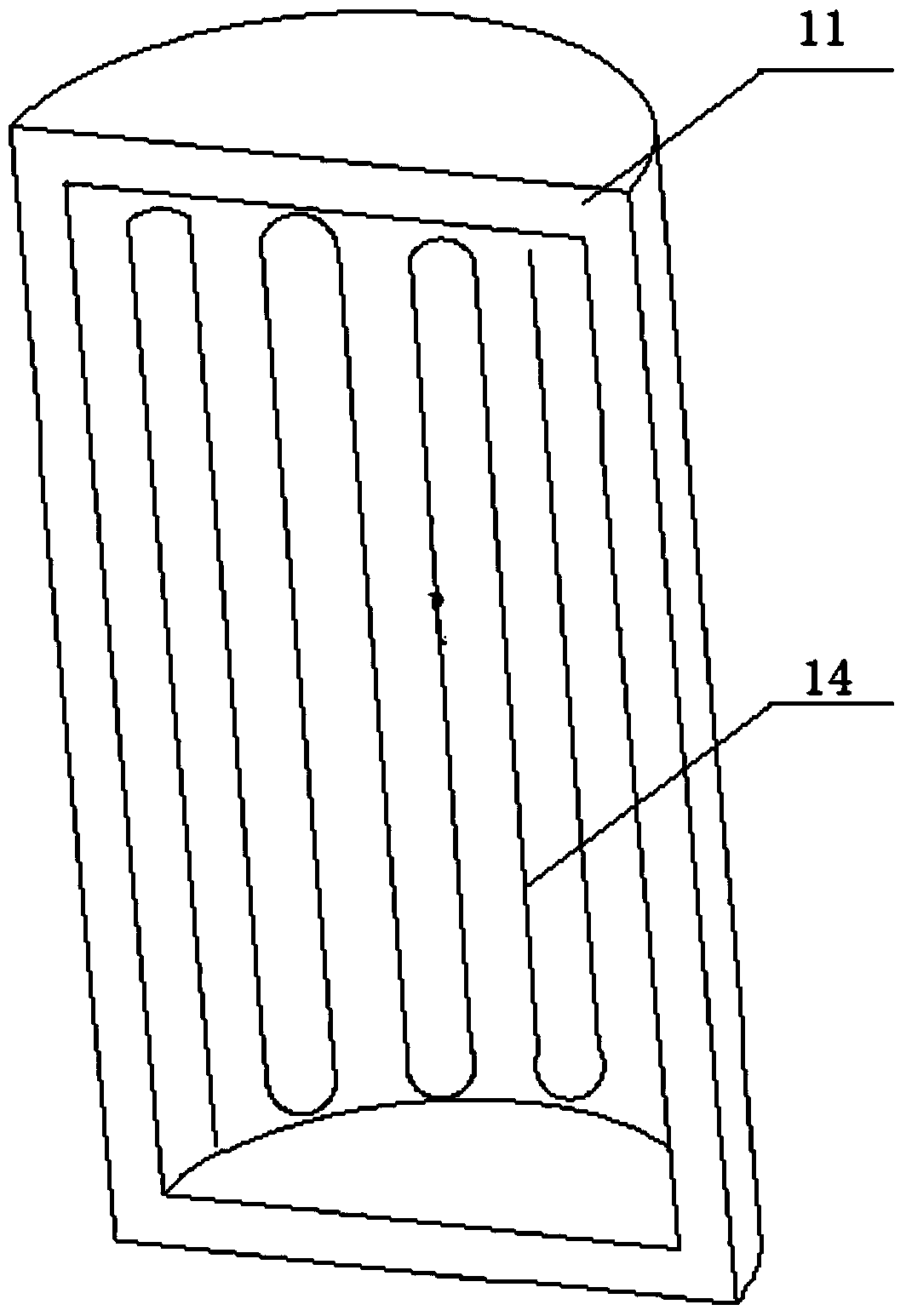

[0043] Step 3.2: Put the industrial salt prepared in step 3.1 into the heating tube, the inner diameter of the heating tube is equal to the inner diameter of the oil and gas pipeline;

[0044] Step 3.3: Turn on the heating tube in step 3.2 to heat until the industrial salt forms agglomerates;

[0045] Step 4: Take out the form...

Embodiment 2

[0050] Step 1: Perform pressure relief and oil discharge on oil and gas pipelines. If the pipeline does not have the conditions for pressure relief and oil discharge, seal the pipeline under pressure to ensure that the pipeline that needs to be equipped with a fireproof wall is free of oil and pressure;

[0051] Step 2: Measure the industrial salt and butter, and weigh them according to the mass percentage, the industrial salt is 50%, the butter is 50%, mix and stir the two, so that the industrial salt and butter are evenly mixed;

[0052] Step 3:

[0053] Step 3.1: Add water to the obtained industrial salt and stir to make the industrial salt moist;

[0054] Step 3.2: Put the industrial salt prepared in step 3.1 into the heating tube, the inner diameter of the heating tube is equal to the inner diameter of the oil and gas pipeline;

[0055] Step 3.3: Turn on the heating tube in step 3.2 to heat until the industrial salt forms agglomerates;

[0056] Step 4: Take out the form...

Embodiment 3

[0061] Step 1: Perform pressure relief and oil discharge on oil and gas pipelines. If the pipeline does not have the conditions for pressure relief and oil discharge, seal the pipeline under pressure to ensure that the pipeline that needs to be equipped with a fireproof wall is free of oil and pressure;

[0062] Step 2: Measure the industrial salt and butter, and weigh them according to the mass percentage, the industrial salt is 60%, the butter is 40%, mix and stir the two, so that the industrial salt and butter are evenly mixed;

[0063] Step 3:

[0064] Step 3.1: Add water to the obtained industrial salt and stir to make the industrial salt moist;

[0065] Step 3.2: Put the industrial salt prepared in step 3.1 into the heating tube, the inner diameter of the heating tube is equal to the inner diameter of the oil and gas pipeline;

[0066] Step 3.3: Turn on the heating tube in step 3.2 to heat until the industrial salt forms agglomerates;

[0067] Step 4: Take out the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com