Method for quickly printing three-dimensional color model

A color model and model technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of single workpiece body, single color, cumbersome and complex, etc., and achieve the effect of high adaptability, uniform color and clear order.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

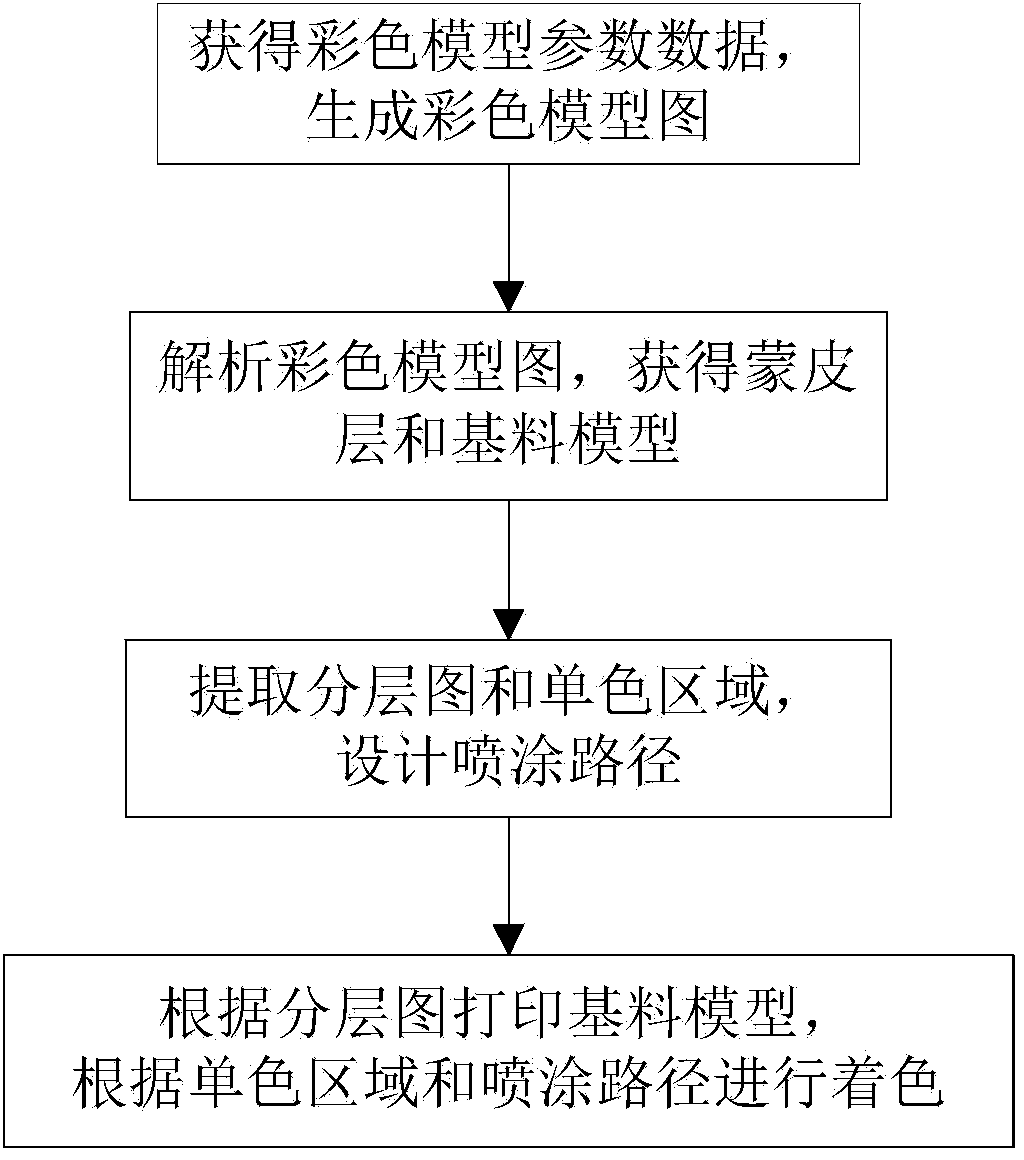

[0018] Such as figure 1 As shown, a fast printing method of a three-dimensional color model proposed by the present invention firstly prints the base material model with the base material, and then colors the outside of the base material model to obtain the color model. The specific steps are as follows:

[0019] S1. Obtain color model parameter data and generate a color model diagram.

[0020] Specifically, a color model image can be obtained through three-dimensional scanning, and a color model diagram can be obtained through graphic processing.

[0021] S2. Analyzing the color model diagram to obtain the skin layer and the base material model.

[0022] The base material model is the main support part of the color model, and the skin layer is the pigment layer covering the base material model.

[0023] S3. Slicing the base material model to extract a layered map; cutting the color area of the skin layer to extract multiple monochrome areas, and designing a spraying path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com