Apparatus and method for automatically removing metal deposits on conveyor belt

An automatic cleaning and conveyor belt technology, which is applied to cleaning devices, conveyor objects, transportation and packaging, etc., can solve problems such as time-consuming, waste of conveyor belt materials, and easily damaged equipment parts, so as to prevent environmental pollution and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

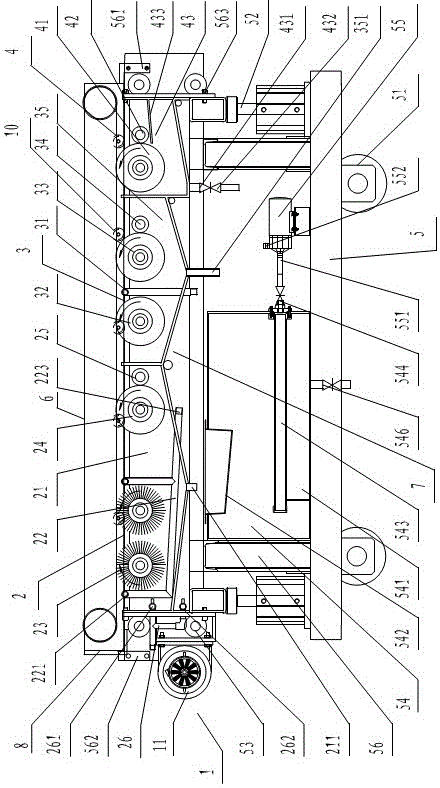

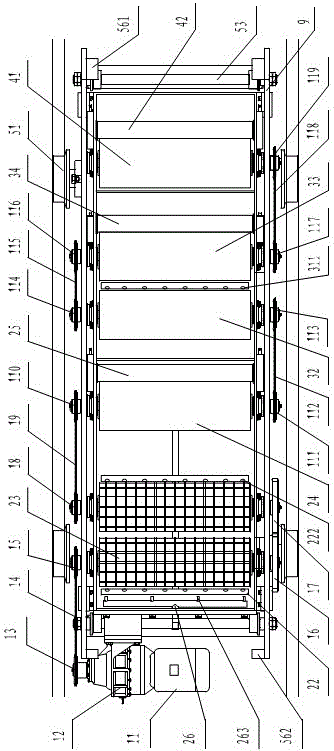

[0026] like figure 1 As shown, the equipment for automatically removing metal deposits on the conveyor belt includes a cleaning transmission device 1, a chemical cleaning device 2, a water scrubbing device 3, an alcohol scrubbing device 4 and a base 5.

[0027] like figure 1 and 2 As shown, the cleaning transmission device 1 includes a motor 11, a speed reducer 12, a sprocket one 13 installed on the speed reducer, a chain one 14, a sprocket two 15, a gear one 16, and a gear two which transmit momentum sequentially with the sprocket one 13 17, sprocket three 18, chain two 19, sprocket four 110, sprocket five 111, chain three 112, sprocket six 113, sprocket seven 114, chain four 115, sprocket eight 116, sprocket nine 117, chain Five 118 and sprocket ten 119.

[0028] Described transmission sprocket group comprises drive brush cleaning roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com