Method for extracting nicotine in tobacco wastewater

A technology for waste water and tobacco, applied in the direction of organic chemistry, etc., can solve problems such as nicotine extraction reports that have not been found, and achieve the effects of reducing pollution discharge pressure, improving efficiency, and reducing organic matter concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

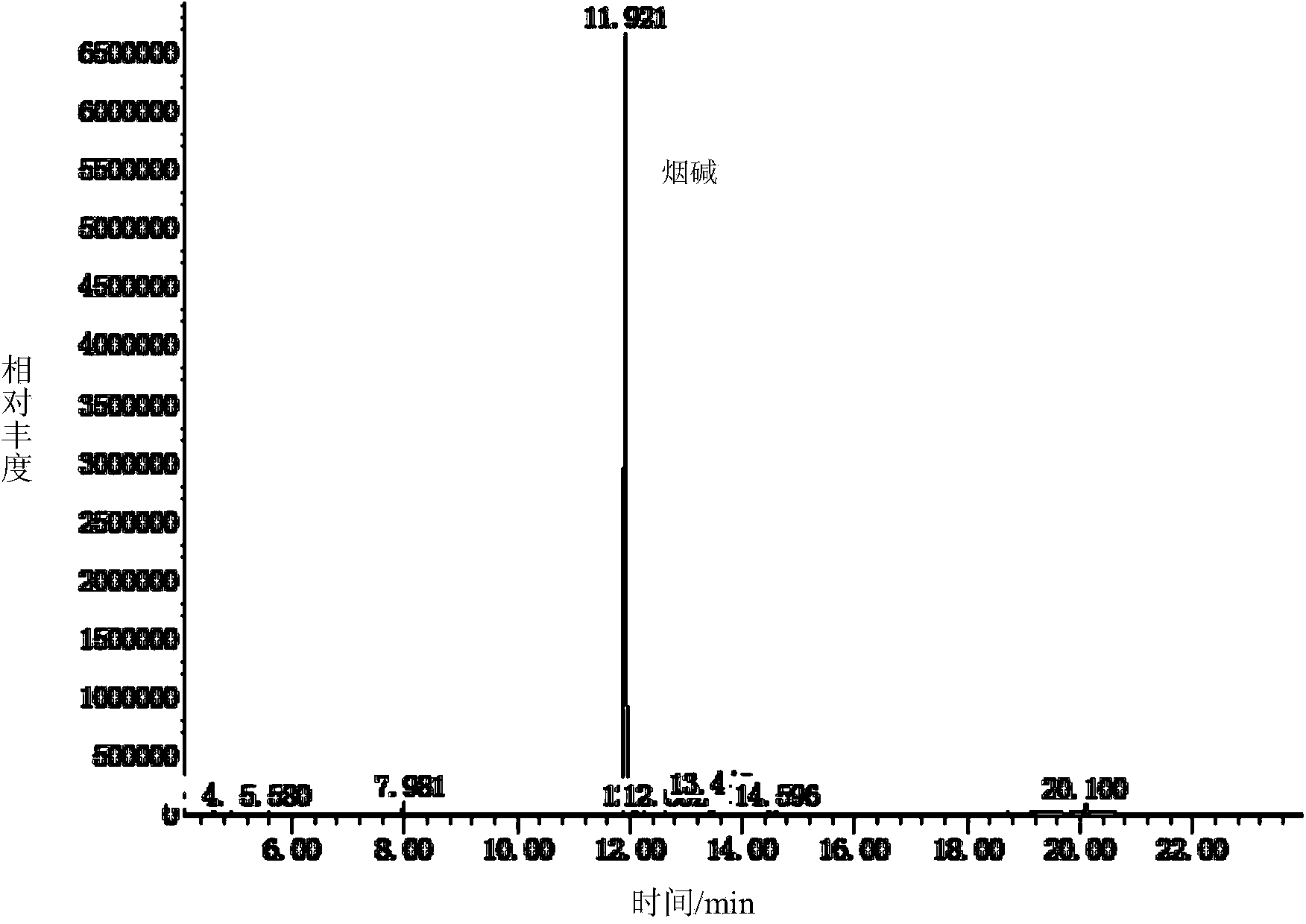

Embodiment 1

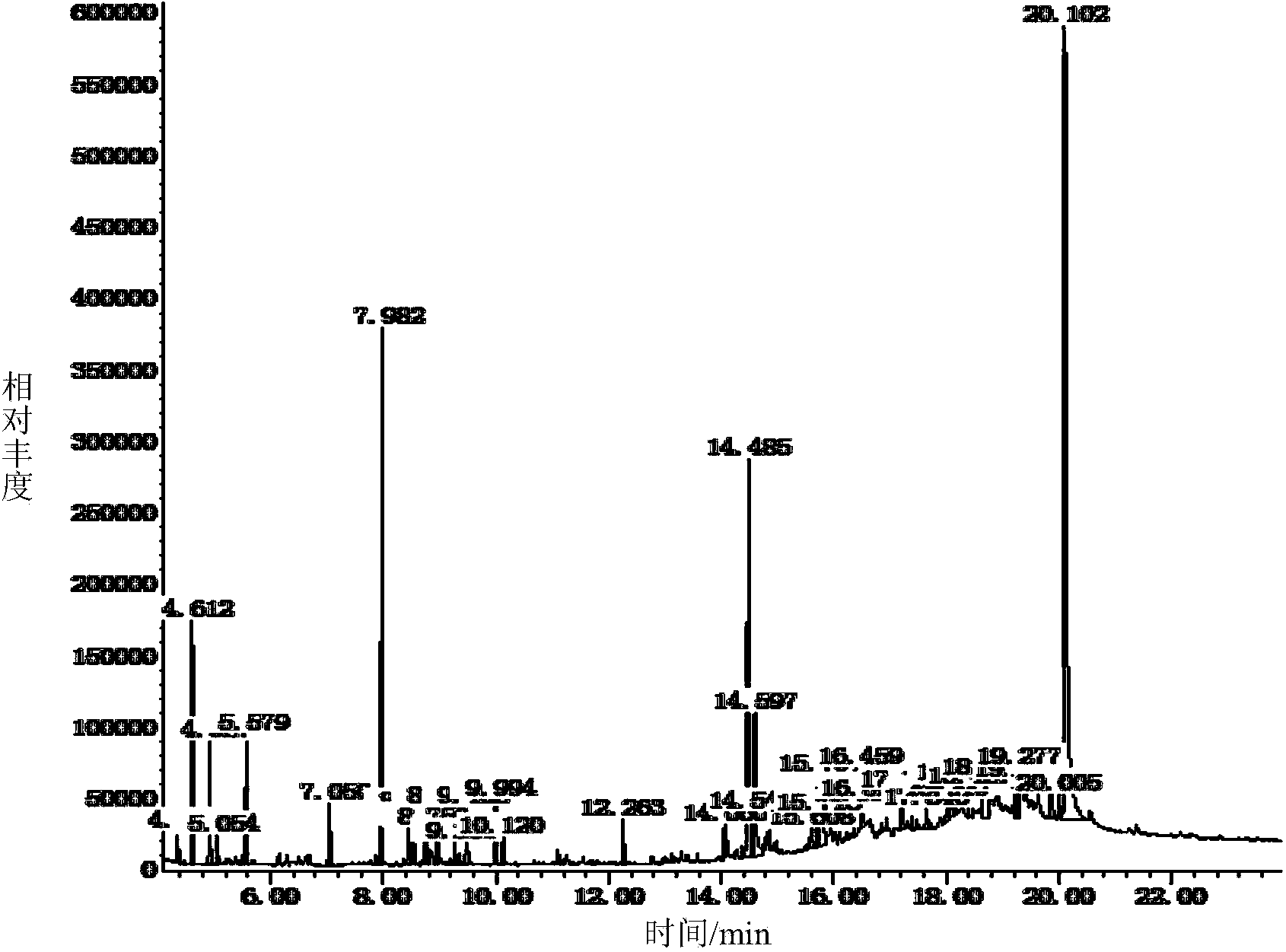

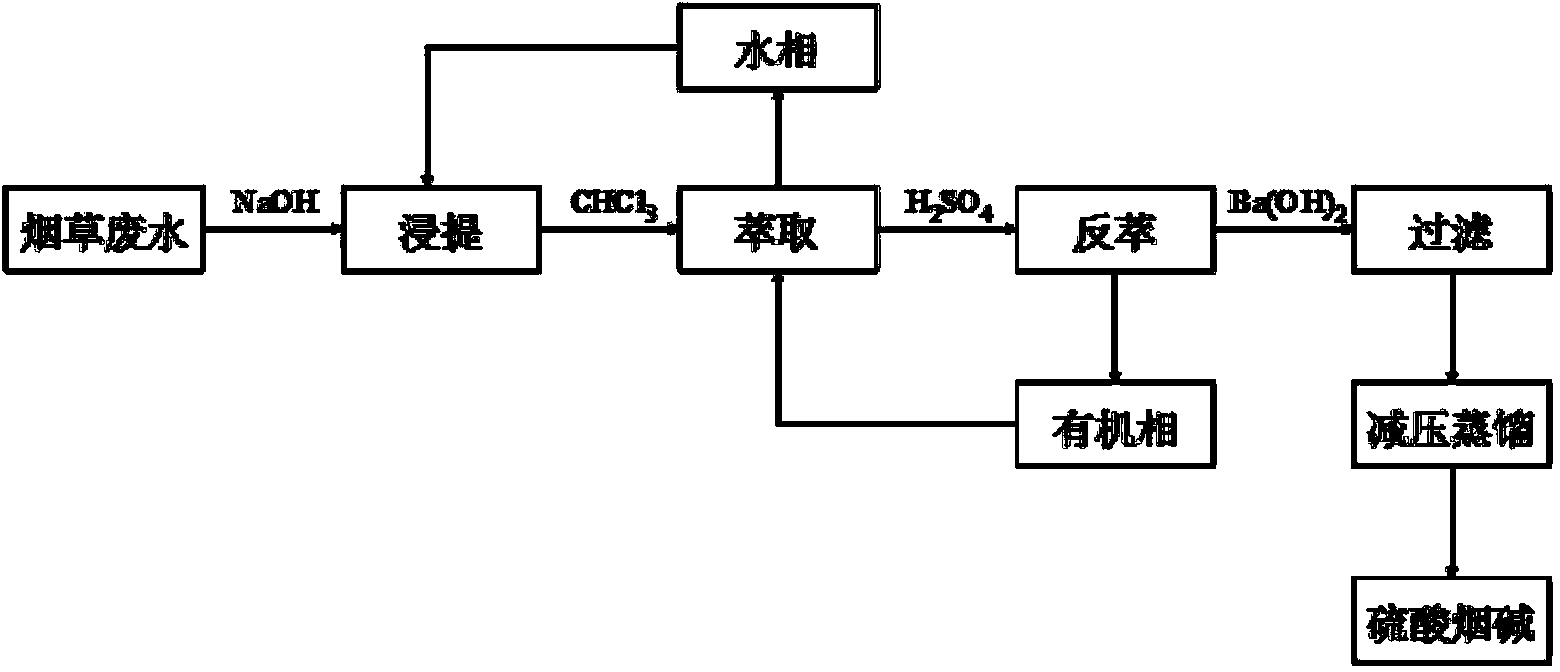

[0026] A method for extracting nicotine in tobacco waste water, the process flow chart is as follows image 3 shown, including the following steps:

[0027] (1) Take 200mL of tobacco flake wastewater, adjust the pH value of the tobacco wastewater to 12 with NaOH solution, stir for 1h (i.e. leaching for 1h), and then add 30mL of CHCl 3 After shaking for 20 minutes, the organic phase is obtained by standing and stratifying; the organic phase enters the next operation of stripping, and the aqueous phase returns to the extraction step;

[0028] (2) add 30% (mass) sulfuric acid solution to the organic phase that step (1) obtains and carry out back extraction, obtain aqueous phase nicotine sulfate solution and organic phase 2, organic phase 2 returns organic phase, and aqueous phase enters next operate;

[0029] (3) Add Ba(OH) to the nicotine sulfate solution obtained in step (2) 2 The excess sulfuric acid was removed from the solution, and then nicotine sulfate was obtained by d...

Embodiment 2

[0033] A method for extracting nicotine in tobacco waste water, comprising the following steps:

[0034] (1) Take 200mL of tobacco flake wastewater, adjust the pH value of the tobacco wastewater to 11 with NaOH solution, stir for 2h, and then add 30mL of CHCl 3 After shaking for 20 minutes, the organic phase is obtained by standing and stratifying; the organic phase enters the next operation of stripping, and the aqueous phase returns to the extraction step;

[0035] (2) adding 20% (mass) sulfuric acid solution to the organic phase obtained in step (1) for back extraction to obtain nicotine sulfate solution;

[0036] (3) Add Ba(OH) to the nicotine sulfate solution obtained in step (2) 2 The excess sulfuric acid was removed from the solution, and then nicotine sulfate was obtained by distillation under reduced pressure.

[0037] After testing, the purity of the obtained nicotine sulfate is 90.76%.

Embodiment 3

[0039] A method for extracting nicotine in tobacco waste water, comprising the following steps:

[0040] (1) Take 200mL of tobacco flake wastewater, adjust the pH value of the tobacco wastewater to 13 with NaOH solution, stir for 2h, and then add 30mL of CHCl 3 After shaking for 30 minutes, the organic phase is obtained by standing and stratifying; the organic phase enters the next operation of stripping, and the aqueous phase returns to the extraction step;

[0041] (2) adding 20% (mass) sulfuric acid solution to the organic phase obtained in step (1) for back extraction to obtain nicotine sulfate solution;

[0042] (3) Add Ba(OH) to the nicotine sulfate solution obtained in step (2) 2 The excess sulfuric acid was removed from the solution, and then nicotine sulfate was obtained by distillation under reduced pressure.

[0043] After testing, the purity of the obtained nicotine sulfate was 91.47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com