Junction structure of bare concrete shear wall and inner filler wall and implementation method thereof

A technology of fair-faced concrete and shear wall, applied in the direction of building structure, wall, building components, etc., can solve the problems of affecting the appearance quality of fair-faced concrete surface, expanding the tie net, weakening the overall error, etc., to achieve flatness and appearance quality. The effect of reducing construction pollution and saving repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

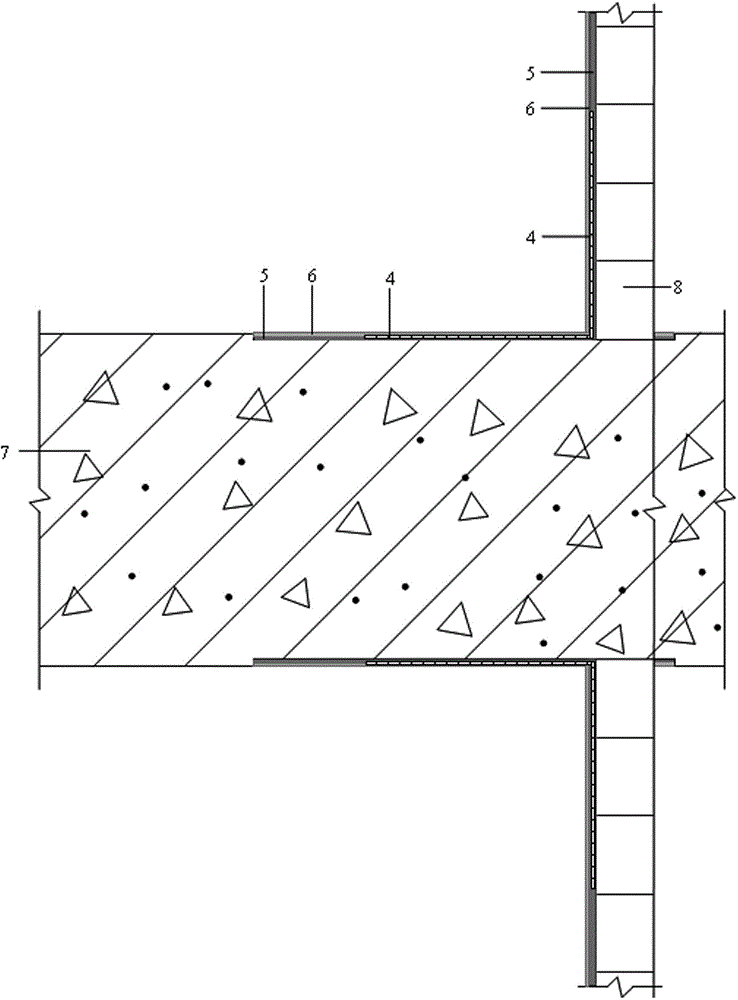

[0020] Such as figure 1 As shown, the structure at the junction of the clear-water concrete shear wall and the inner filling wall includes the clear-water concrete shear wall 7 and the inner filling wall 8. The two sides of the shear wall 7 are concave at the vertical junction with the inner filling wall 8, forming a Shaped concave surface, the concave surface is bonded to the inner filling wall 8 after the base plastering through alkali-resistant glass fiber mesh cloth 4 and plain cement slurry 5 mixed with 108 glue (amount of 20%), and mixed with 108 glue (amount of 15%) %) of 1:2 cement slurry 6 for surface plastering, and the part of the shear wall 7 located on the concave surface is plastered with cement slurry 6 and the surface is at the same level as the rest of the surface.

Embodiment approach

[0021] The implementation method of above-mentioned structure, comprises the following steps:

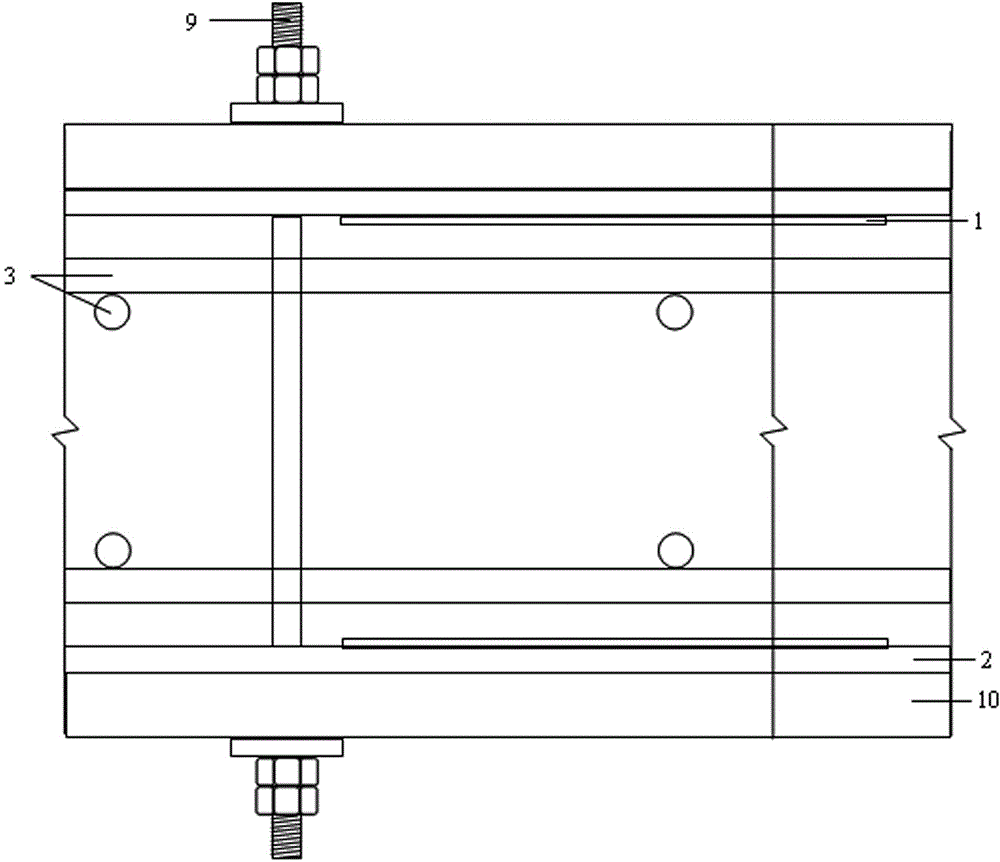

[0022] (1) Use bamboo plywood 2 with a thickness of 9mm to make a shear wall formwork, such as figure 2 As shown, the reinforcement mesh 3 is installed inside the formwork, the two sides of the formwork are tightened with pull bolts 9, the formwork is externally fixed with section steel supports 10, and the inner wall of the formwork is located at the vertical intersection of the shear wall 7 and the inner filling wall 8. Fix the rectangular shape with self-tapping wood screws Steel plate 1; wherein, the thickness of the rectangular steel plate 1 is 2.5 mm, its length is the length of the junction of the shear wall 7 and the inner filling wall 8, and its width is 300 mm+thickness of the inner filling wall 8;

[0023] (2) Pour fair-faced concrete into the formwork, and form a shear wall 7 after forming and removing the formwork. The surface of the shear wall 7 is located at the rect...

Embodiment 2

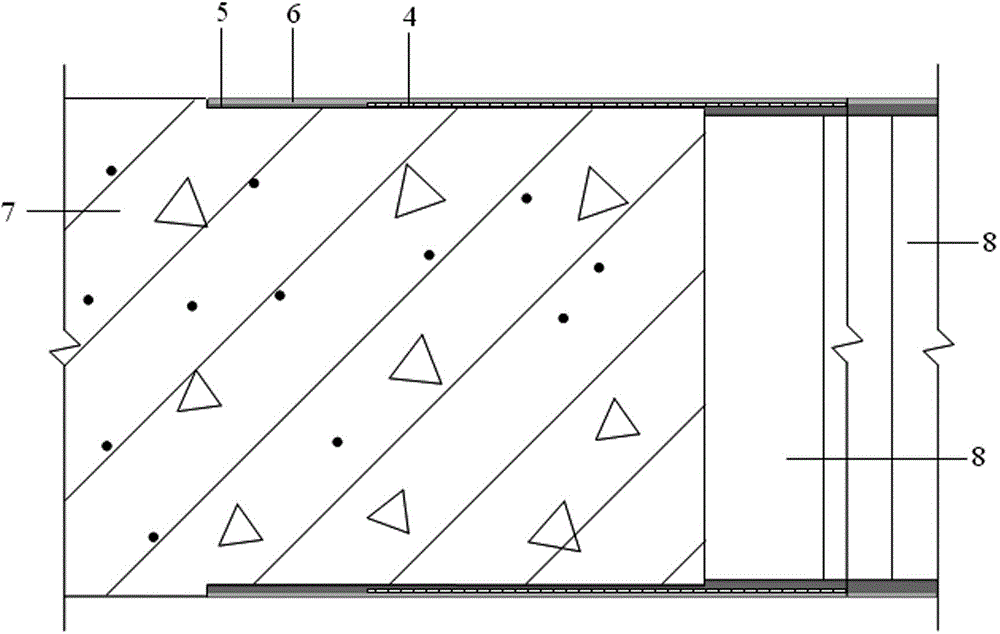

[0027] Such as image 3 As shown, the structure at the junction of the fair-faced concrete shear wall and the inner filling wall includes the fair-faced concrete shear wall 7 and the inner filling wall 8, and the shear wall 7 is concave on both sides of the horizontal junction with the inner filling wall 8, forming strip Shaped concave surface, the concave surface is bonded to the inner filling wall 8 after the base plastering through alkali-resistant glass fiber mesh cloth 4 and plain cement slurry 5 mixed with 108 glue (amount of 20%), and mixed with 108 glue (amount of 15%) %) of 1:2 cement slurry 6 for surface plastering, and the part of the shear wall 7 located on the concave surface is plastered with cement slurry 6 and the surface is at the same level as the rest of the surface.

[0028] The implementation method of above-mentioned structure, comprises the following steps:

[0029] (1) Use bamboo plywood 2 with a thickness of 9 mm to make a shear wall formwork, such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com