Glass reinforced fiber pull-extrusion skirt board

A skirting board and fiberglass technology, which is applied in the direction of construction and building construction, can solve the problems of low elastic modulus, low shear strength, and performance degradation, and achieve the effects of high load factor, high work efficiency, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

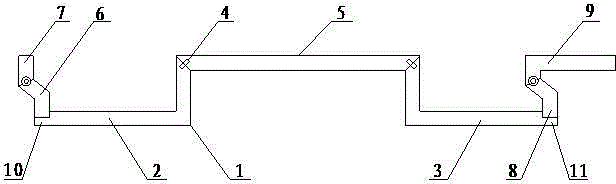

[0020] Embodiment 1: The overall length of the plate body 1 is 100 mm, the overall height of the plate body 1 is 12 mm, and the thickness of the plate body 1 is 3 mm.

Embodiment 2

[0021] Embodiment 2: The overall length of the board body 1 is 148 mm, the overall height of the board body 1 is 14 mm, and the thickness of the board body 1 is 3 mm.

Embodiment 3

[0022] Embodiment 3: The overall length of the board body 1 is 124 mm, the overall height of the board body 1 is 13 mm, and the thickness of the board body 1 is 3 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com