Disc Stirling engine heat collector port heat shield device and application thereof in solar power generation

A Stirling engine and heat collector technology, applied in the field of solar power generation, can solve problems such as large losses, and achieve the effects of reducing heat, suppressing convective heat transfer, and enhancing reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in further detail:

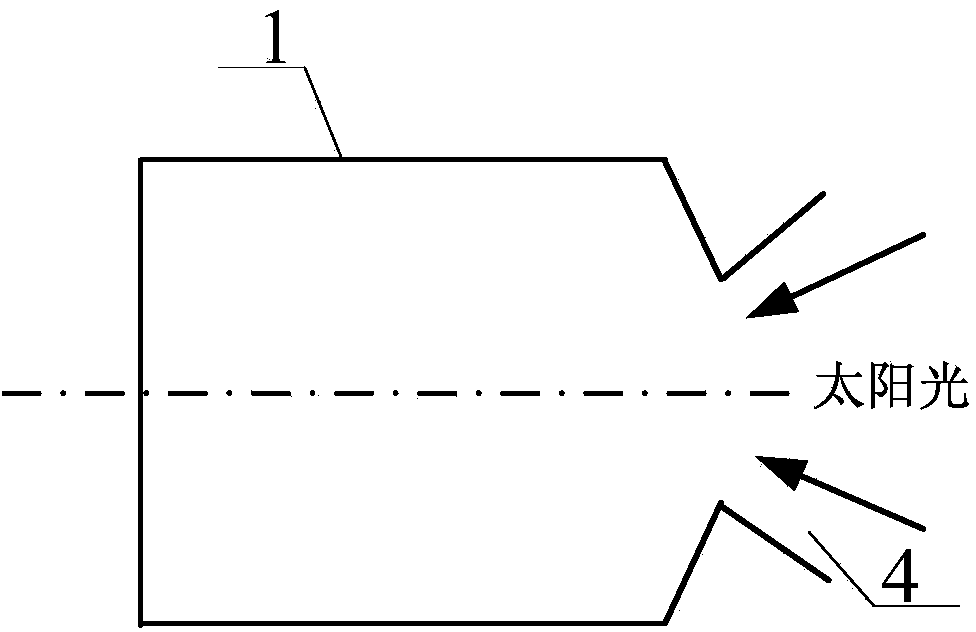

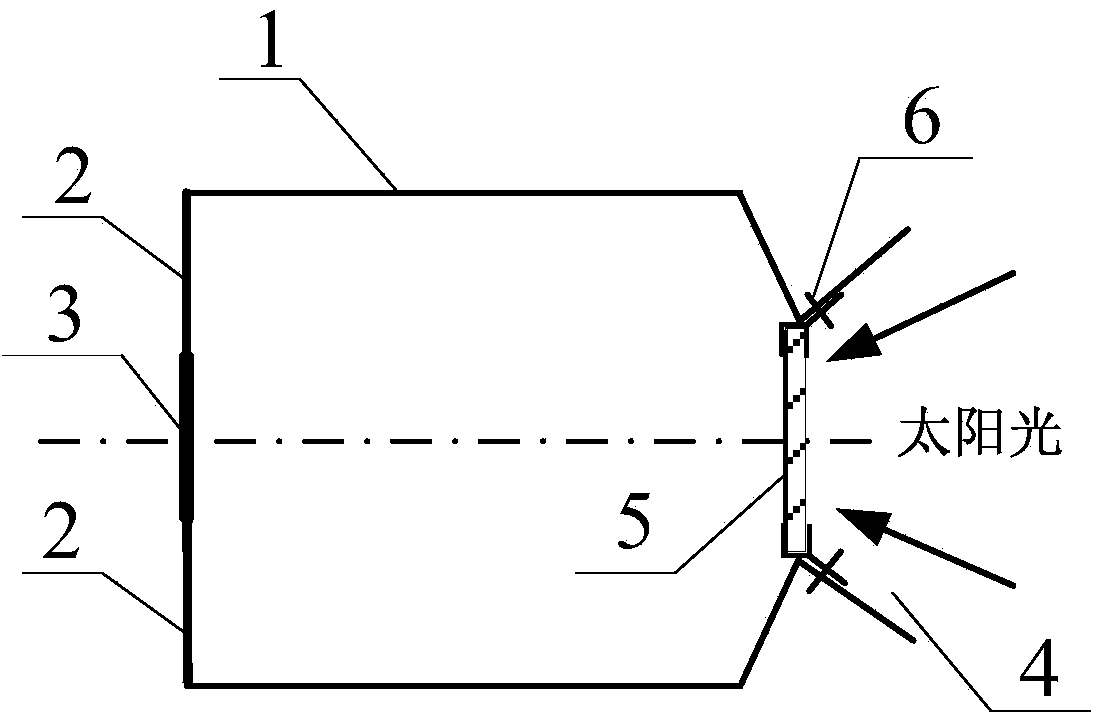

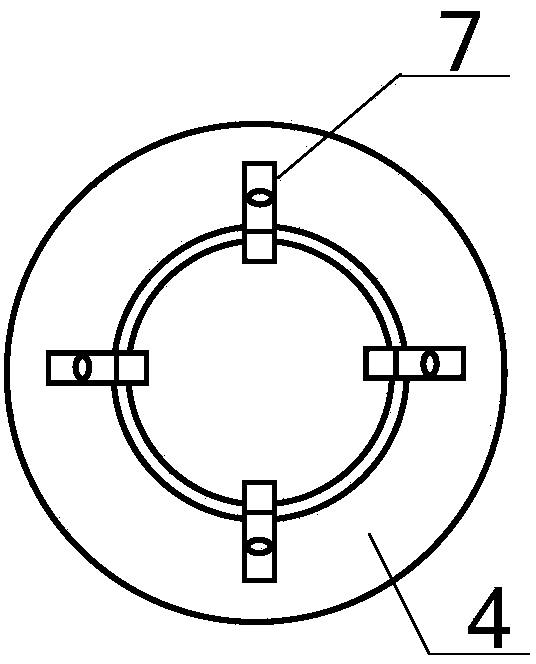

[0036] refer to Figure 5 and Figure 6 , the present invention comprises a cylindrical heat-collecting chamber, the heat-collecting chamber wall is composed of a heat-insulating and heat-preserving component 1, and the heat-insulating and heat-preserving component 1 can be made of a conventional heat-preserving material, and its inner surface is coated with a second reflective film with a reflectivity not less than 94%. , and can reduce radiant heat loss by 2-3kW; the bottom of the heat collecting chamber is closed, and is provided with a ring-shaped heat-absorbing part 2 for absorbing sunlight for conversion. and the ceramic 3 that reflects sunlight; the mouth 4 of the heat collecting cavity is formed by docking the small ports of two cones, wherein the large port of the inner cone is connected to the heat collecting cavity; the connection of the small ports of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com