Fire channeling prevention device for fuel air explosive warhead

A warhead and anti-jumping technology, applied in the field of cloud explosion warheads, can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

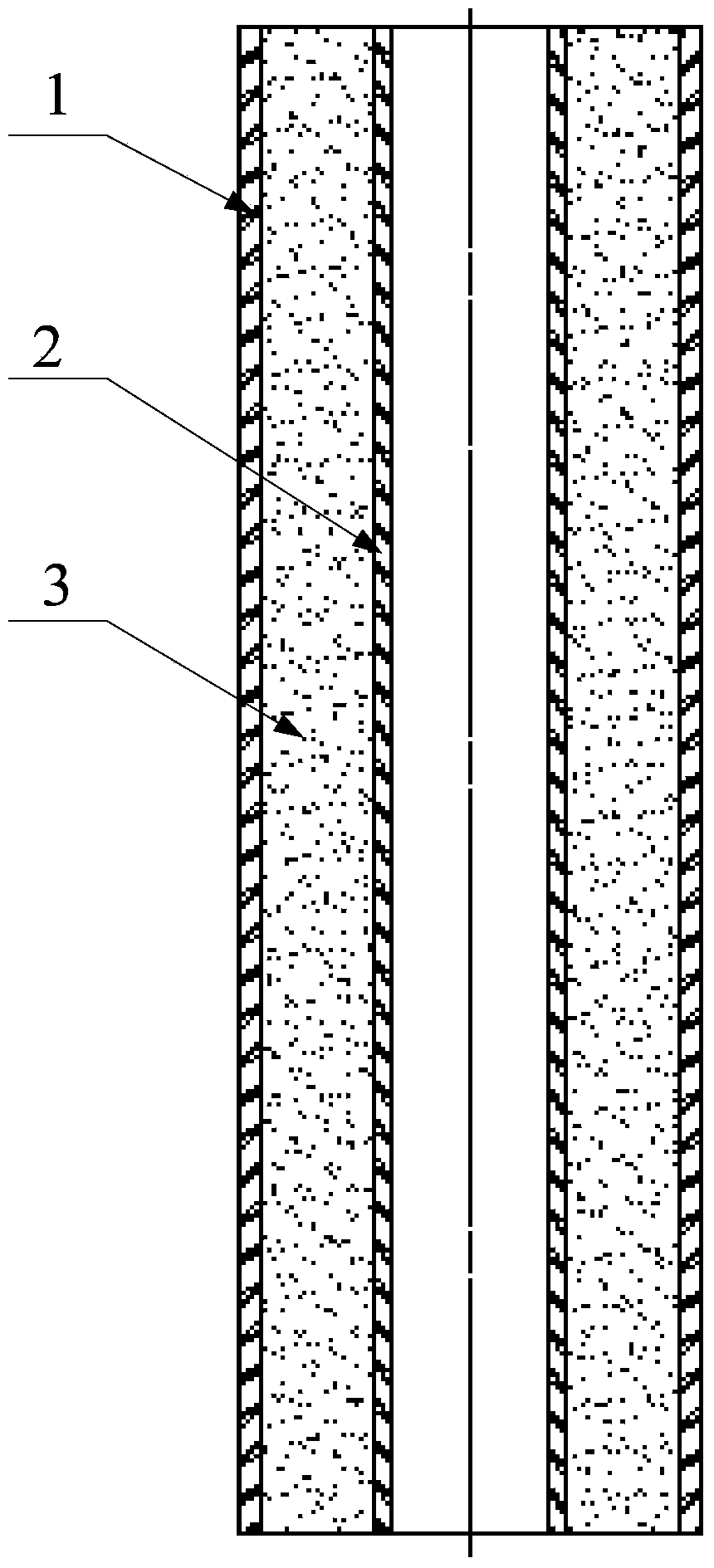

Image

Examples

Embodiment 1

[0037] The outer diameter of the cloudburst warhead shell is 200mm, and the height is 300mm.

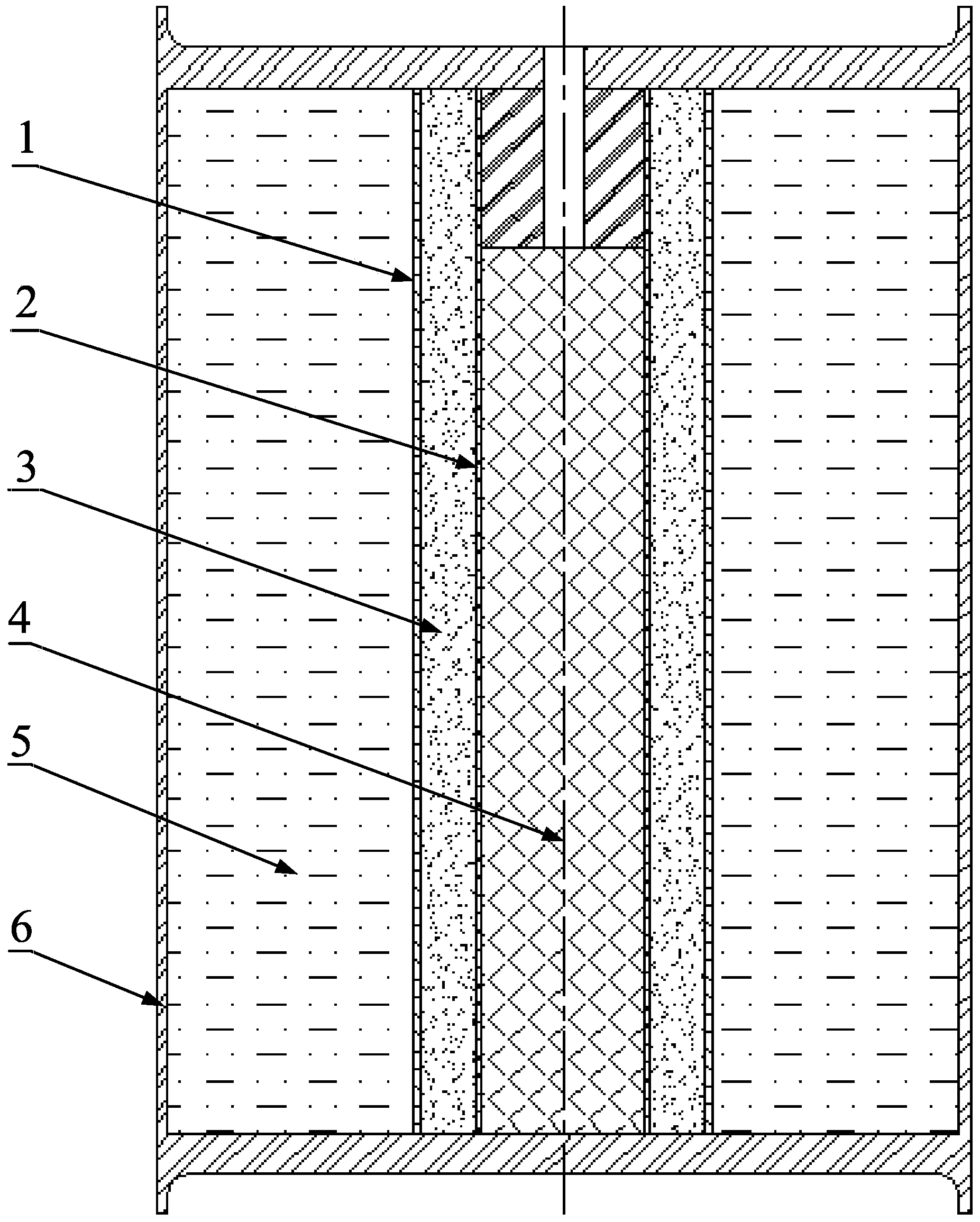

[0038] Fix the anti-jump fire device on the shell of the cloud explosion warhead (see attached figure 2 ), the inner cylinder (inner diameter 40mm, wall thickness 1.5mm) and outer cylinder (inner diameter 70mm, wall thickness 1.5mm) of the fire prevention device should coincide with the axis of the cloud explosion warhead shell;

[0039] Fill cloud explosion medicament (propylene oxide) between the shell of cloud explosion warhead shell and the anti-jump fire device then;

[0040] Then, ammonium bicarbonate is filled between the outer cylinder and the inner cylinder of the fire prevention device, and the density of the filled ammonium bicarbonate is 1.51g / cm 3 , the filling mass is 940g.

[0041] Then fill the throwing powder column (TNT powder column, Φ40×40mm, 7 sections) inside the inner cylinder of the fire prevention device; finally insert the detonator on the upper part of t...

Embodiment 2

[0044] The outer diameter of the cloudburst warhead shell is 400mm, and the height is 600mm.

[0045] Fix the anti-jump fire device on the shell of the cloud explosion warhead, and make the inner cylinder (inner diameter 80mm, wall thickness 2mm) and outer cylinder (inner diameter 140mm, wall thickness 2mm) of the anti-jump fire device and the shell of the cloud explosion warhead The axis coincides;

[0046] Then in the cloud burst warhead shell (see attached figure 2 ) and the shell of the fire prevention device are filled with cloud explosion agent (propylene oxide);

[0047] Then, ammonium bicarbonate is filled between the outer cylinder and the inner cylinder of the fire prevention device, and the density of the filled ammonium bicarbonate is 1.51g / cm 3 , the filling mass is 8327g;

[0048] Then fill the throwing powder column (TNT powder column, Φ80×80mm, 7 sections) inside the inner cylinder of the fire prevention device; finally insert the detonator on the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com