Standard pose calibration method for six-degree-of-freedom parallel robot used for Stewart platform structure

A calibration method and robot technology, which can be applied to instruments, measuring devices, navigation and calculation tools, etc., can solve the problems of difficult implementation and low computing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

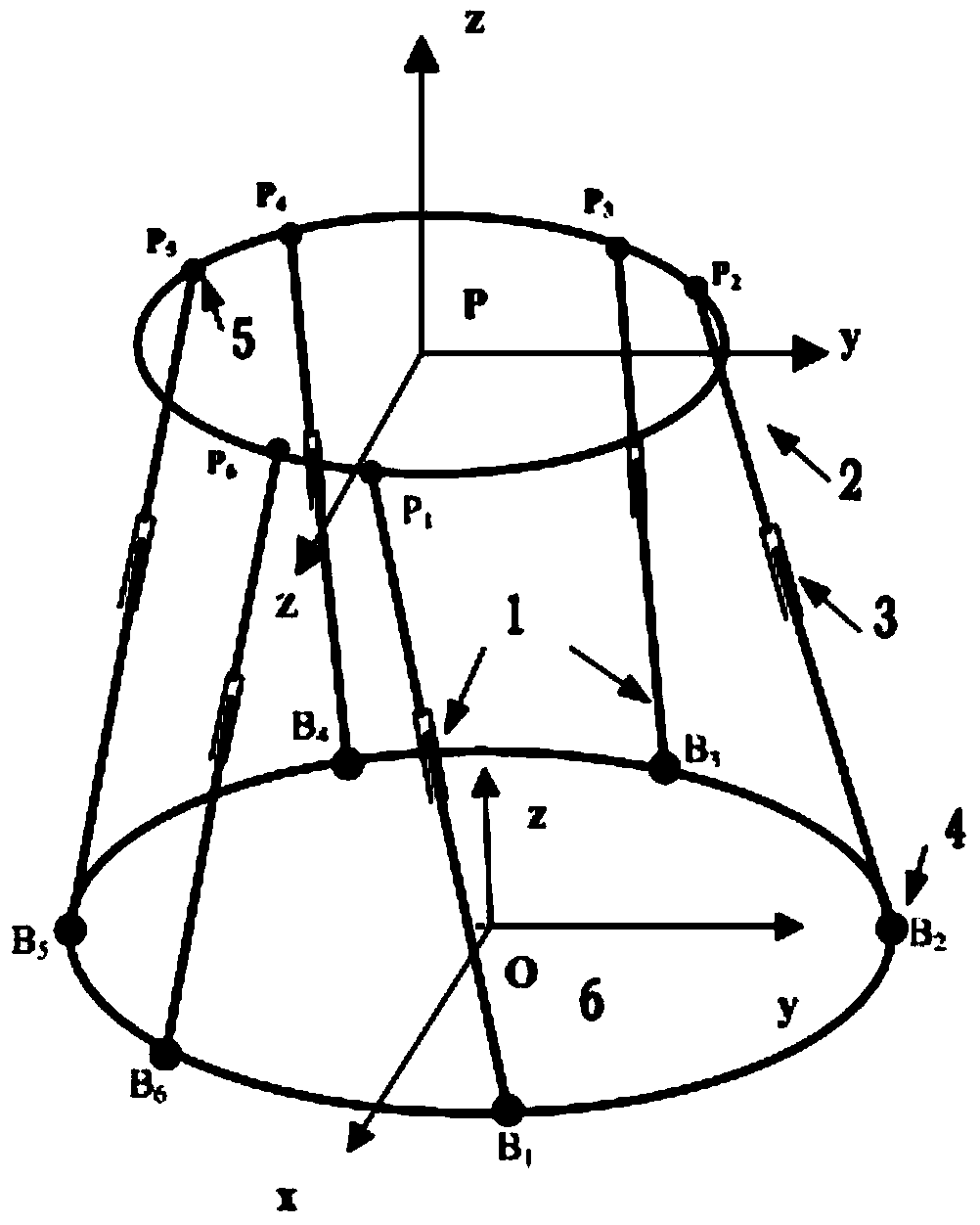

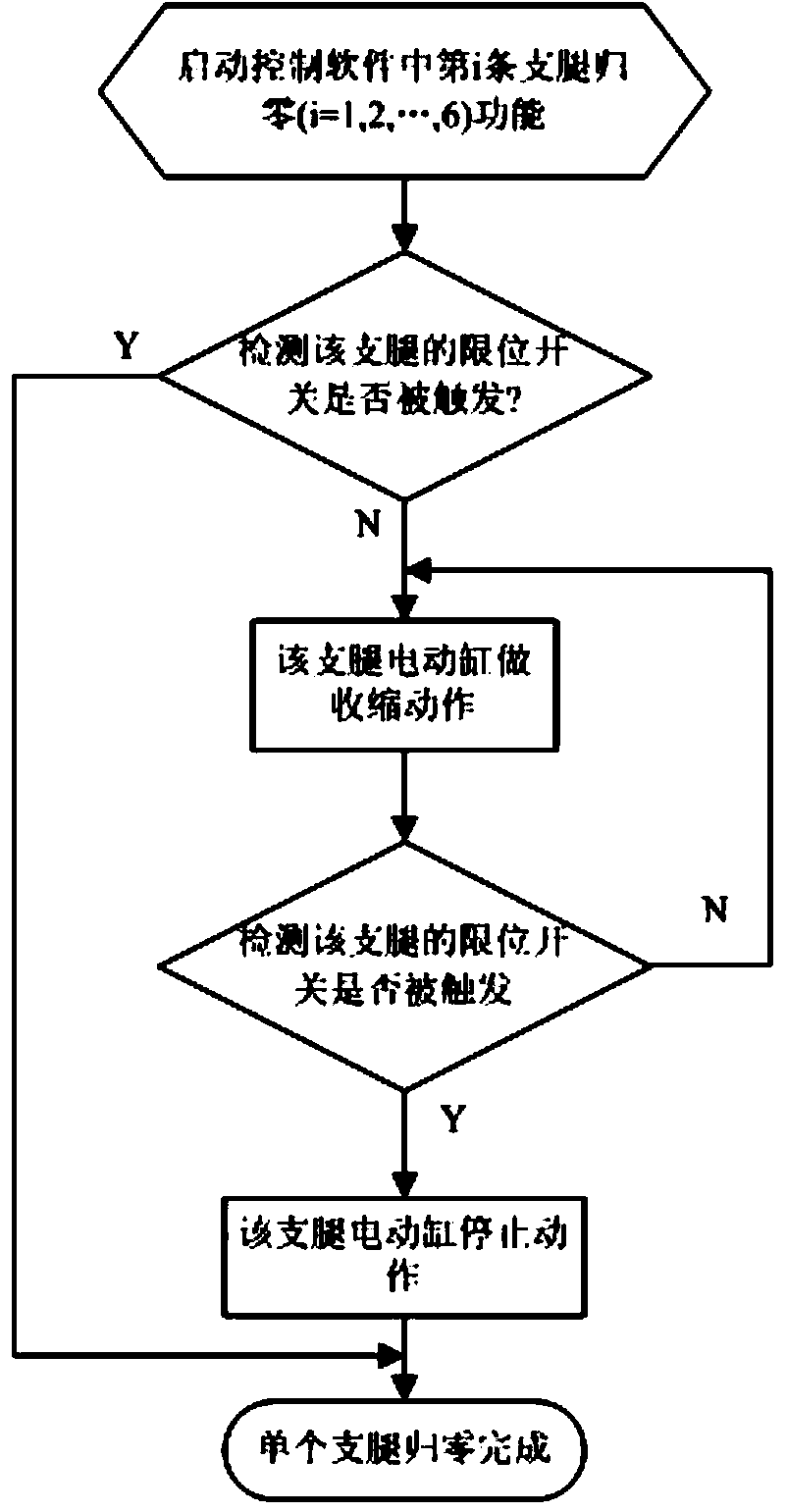

[0062] Such as figure 1 Shown is the six-degree-of-freedom parallel robot that is used for Stewart platform configuration of the present invention, and its benchmark pose calibration method comprises the following steps:

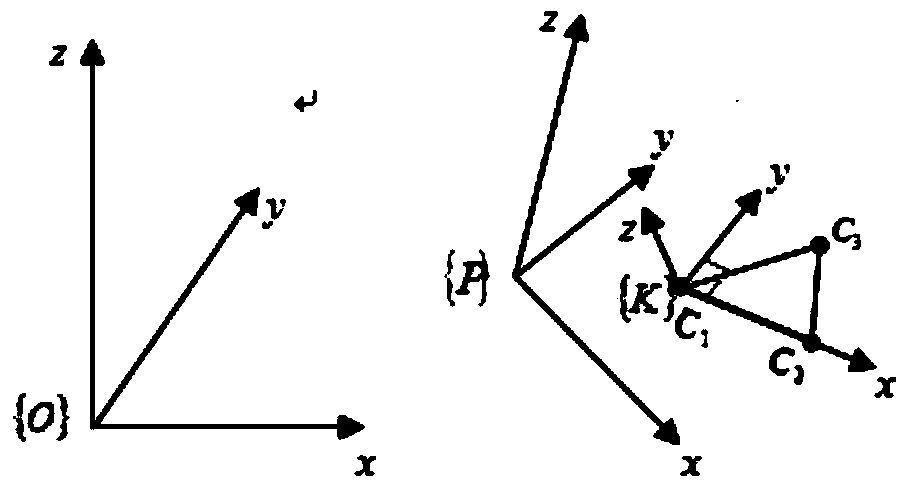

[0063] 1. Establish the base coordinate system {O} on the base of the parallel robot and the motion platform coordinate system {P} on the motion platform.

[0064] 2. In the case of an open-chain six-degree-of-freedom parallel robot mechanism, use a three-coordinate measuring instrument, such as figure 1 As shown, calibrate the center B of the six Hookee hinges of the parallel robot i and 6 spherical hinge centers P i Position coordinate vectors under {O} and {P} respectively O b i and P p i ; Among them, the subscript i=1,2,...,6 indicates the sequence numbers of Hookee hinges and spherical hinges.

[0065] 6 Hooker H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com