C0 complexity and correlation coefficient-based milling chatter detection method

A technology of correlation coefficient and detection method, applied in measuring devices, measuring/indicating equipment, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of time-consuming calculation, poor robustness, sensitivity to changes in working conditions, etc., and achieve a small amount of calculation. , the effect of good accuracy and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

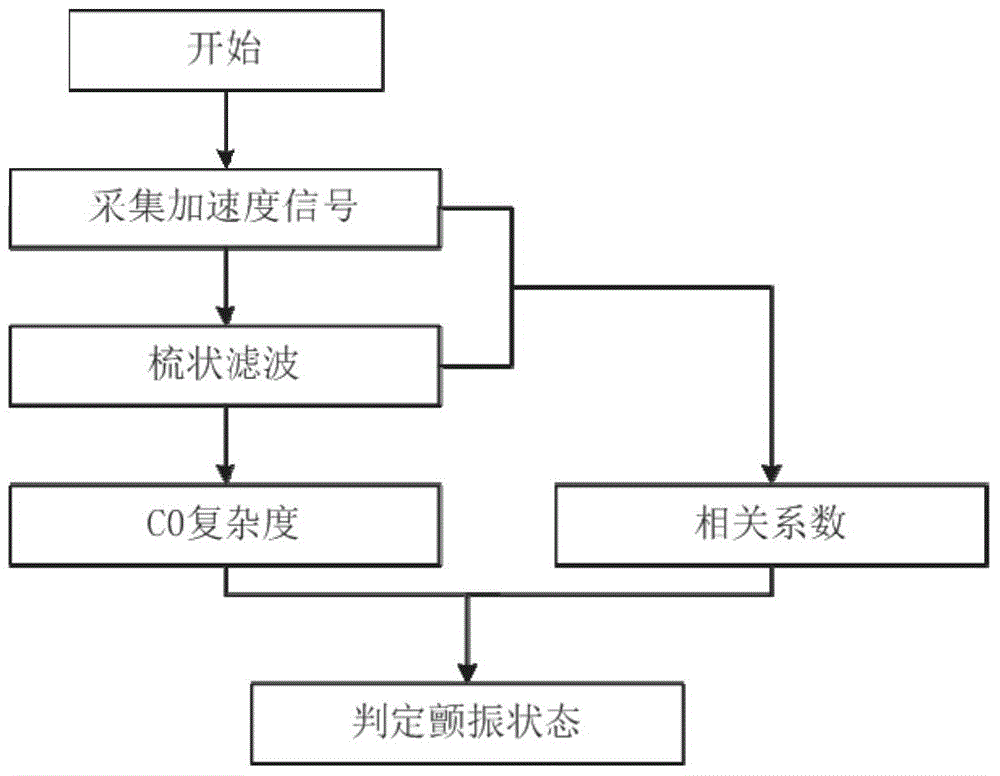

[0040] refer to figure 1 , the present invention is based on C 0 The milling chatter detection method of complexity and correlation coefficient comprises the following steps:

[0041] 1) Acquisition of signal:

[0042] Vibration information during milling is collected through a vibration acceleration sensor (sensitivity of 10.09mv / g) arranged at the end of the high-speed spindle, and the obtained signal is expressed as X=[x(1),x(2),…,x(n)] , n represents the signal length.

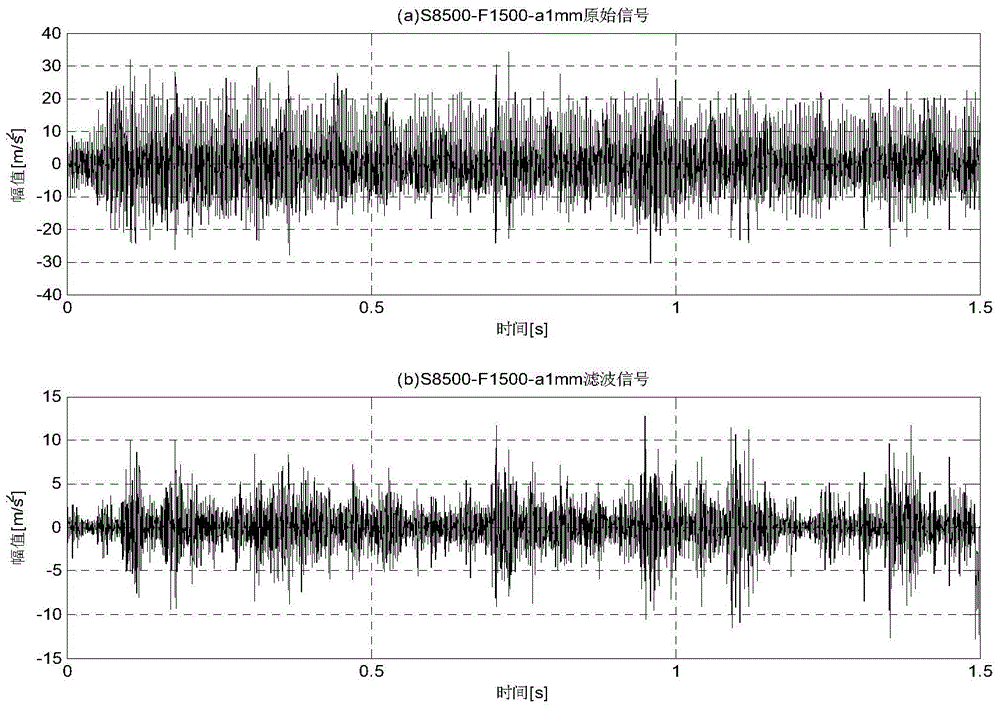

[0043] 2) Comb filtering of the signal:

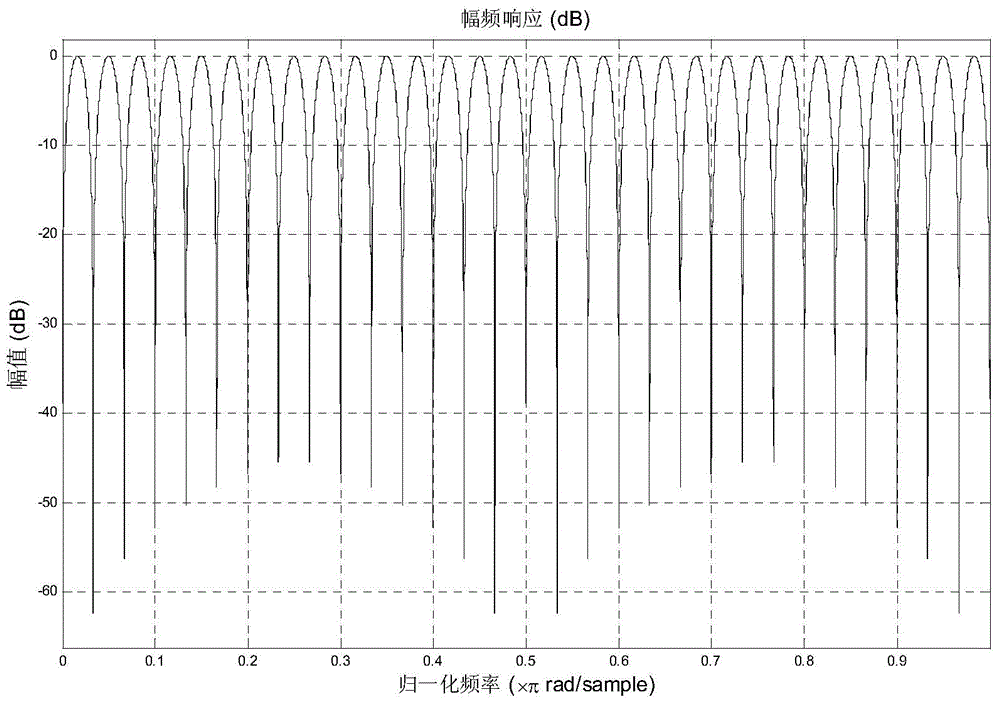

[0044] The transfer function of the comb filter system is where N is the filter order, (N is an integer), f s is the sampling frequency (Hz), is the frequency to be filtered out (Hz), Ω is the spindle speed (r / min), and a is a constant between 0 and 1. When a increases, the filter frequency response curve is fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com