Automatic testing device for three-phase aftercurrent action protector

An automatic test device and residual current technology, applied in circuit breaker testing, measuring devices, instruments, etc., can solve the problems of low test current stability and accuracy, poor flexibility, and low accuracy, and achieve effective operating characteristics and Temperature rise characteristics, high stability and precision, and the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

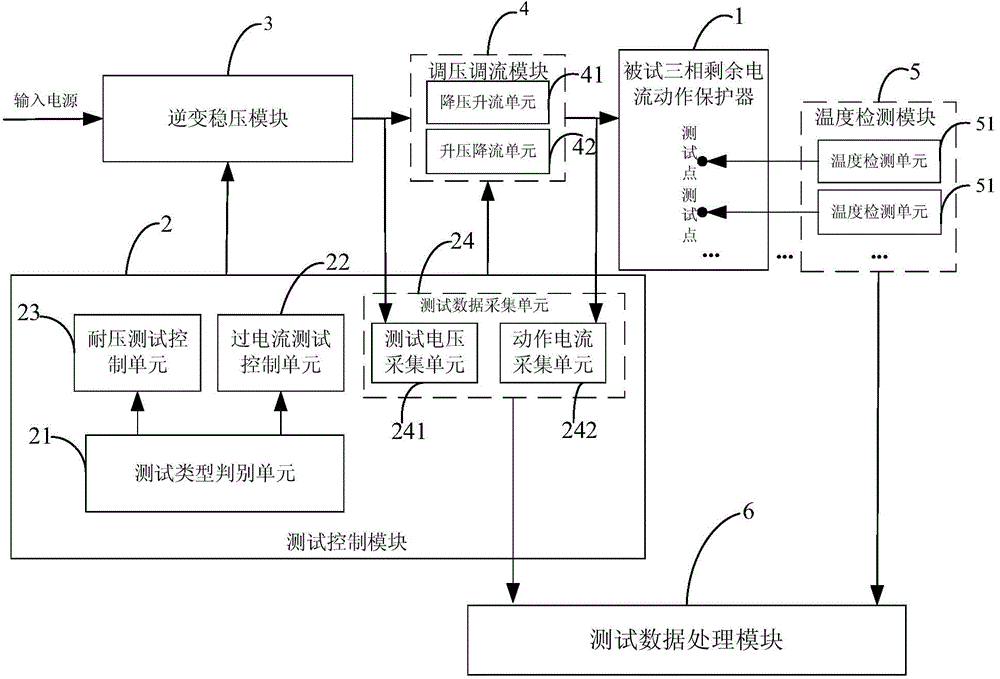

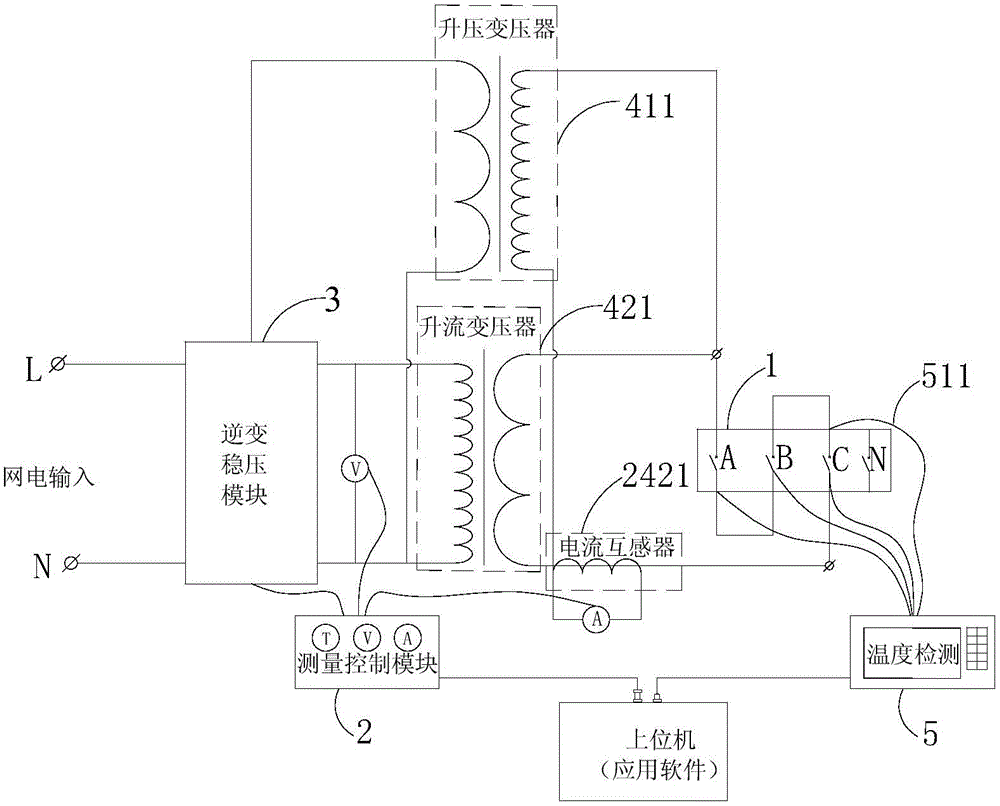

[0025] Such as figure 1 , 2 As mentioned above, the automatic test device of the three-phase residual current operating protector in this embodiment includes a test control module 2, an inverter voltage stabilization module 3, a voltage regulation and current regulation module 4, and a temperature detection module 5. The test control module 2 is based on the test type Control the inverter and voltage stabilization module 3 to invert and stabilize the input power, and the voltage regulation and current regulation module 4 boosts the voltage or current of the power signal after inversion and voltage stabilization to obtain the required test current, test voltage and Provided to the tested three-phase residual current operated protector 1, the temperature detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com