Expert system based numerically-controlled machine tool fault diagnosis system

A fault diagnosis system, a technology of CNC machine tools, applied in general control systems, control/regulation systems, program control, etc., can solve the problem of lack of remote data communication function, lack of equipment operating status monitoring, and the inability of traditional controllers to keep up with fault diagnosis technology and other problems to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

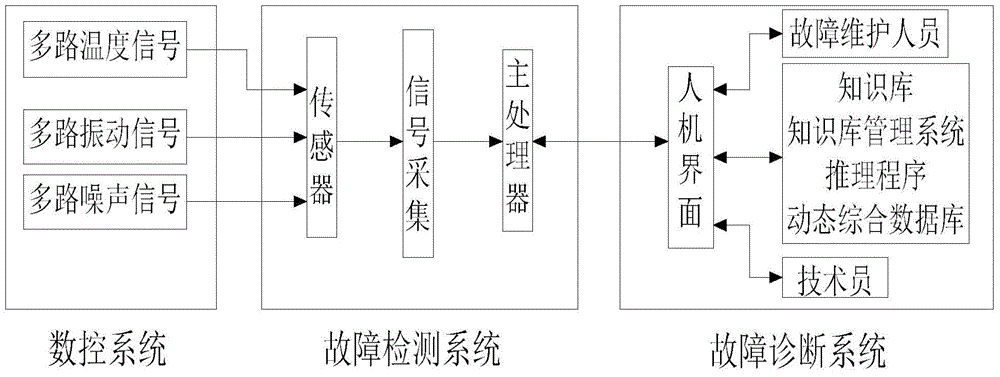

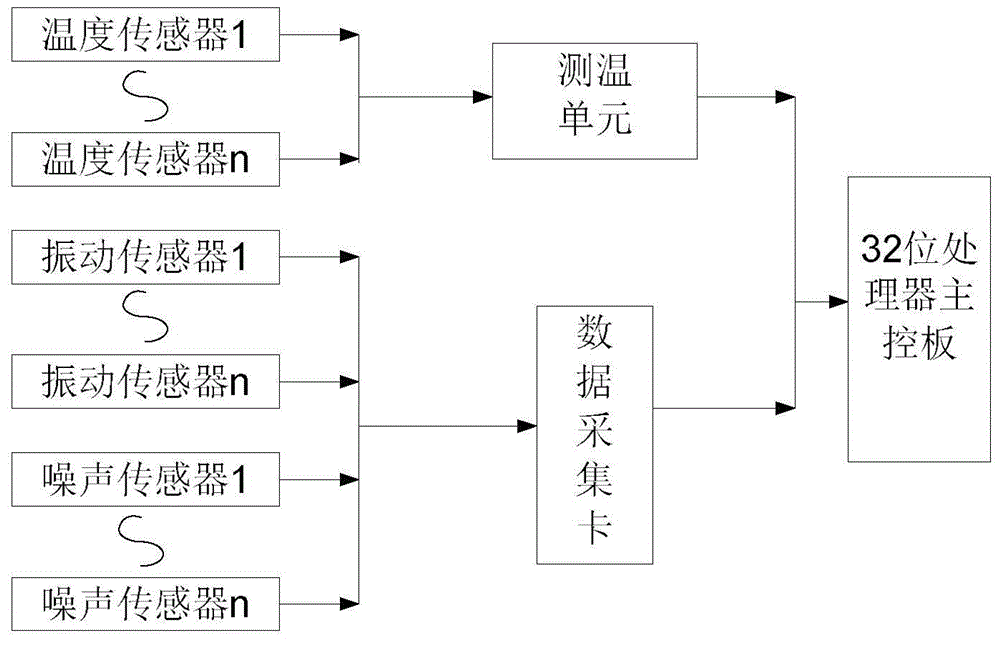

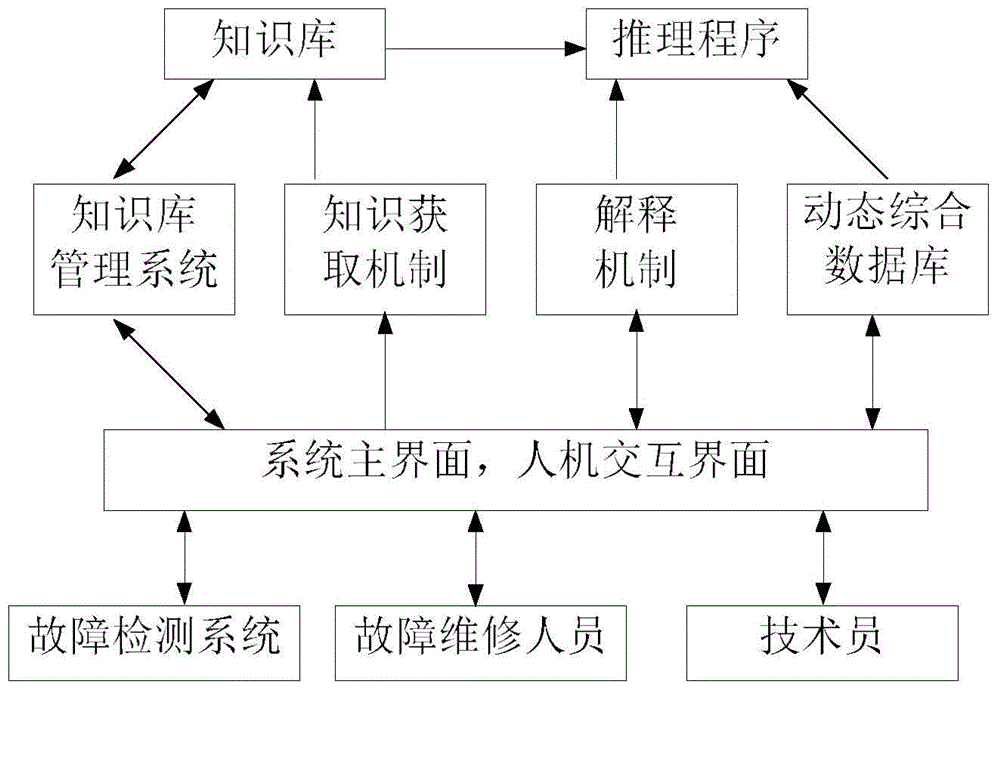

[0023] The present invention mainly studies bus-based data acquisition and processing technology and fault intelligent diagnosis technology, and obtains a set of numerical control system intelligent diagnosis module with remote fault diagnosis function, which can be used in conjunction with numerical control system, thereby improving the reliability of numerical control system operation . to combine figure 1 , figure 2 and image 3 As shown, a fault diagnosis system for CNC machine tools based on an expert system in this embodiment includes a fault detection system for multi-sensor real-time data collection and a fault diagnosis system based on an expert system is developed on the basis of processing and intelligent analysis of collected data. diagnostic system. figure 1 The sensors in the system include temperature sensors, vibration sensors and noise sensors; signal acquisition includes the acquisition of temperature signals, vibration signals, and noise signals, among w...

Embodiment 2

[0032] An expert system-based fault diagnosis system for CNC machine tools in this embodiment is basically the same as that in Embodiment 1, except that the temperature sensor and the temperature measuring unit are different. The temperature signal acquisition method in this embodiment is adopted to improve the accuracy of temperature acquisition, so as to provide reliability and stability of the entire diagnostic system.

[0033] Regarding temperature signal acquisition, the traditional Pt1000 temperature signal processing circuit adopts ordinary bridge circuit or four-wire constant current source drive circuit. Among them, the main defects of the ordinary bridge circuit are: ① Since the reference voltage of the AD converter in the ordinary bridge circuit is an independent high-precision reference voltage source, the digital output of the AD converter has a nonlinear relationship with the Pt1000 resistance ;② Ordinary bridge circuits must use high-precision reference voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com