Worm wheel type driving pipeline robot system based on high-strength spring wall press apparatus

A pipeline robot, high-strength technology, applied in control/adjustment system, two-dimensional position/channel control, vehicle position/route/height control, etc., can solve problems such as difficult stable operation, poor control effect, etc., to avoid Accidental injury, realization of online detection and diagnosis, and effect of ensuring effective detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

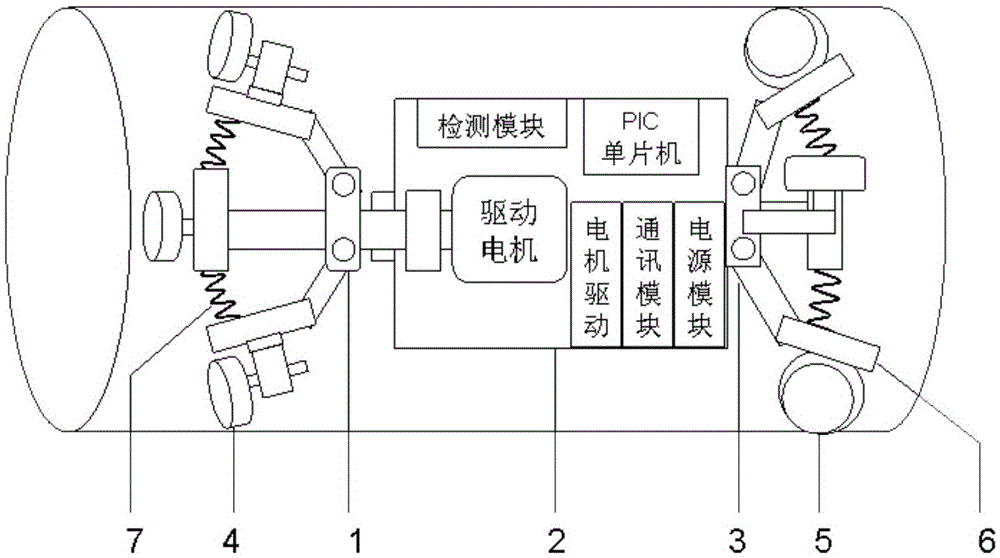

[0040] Example: A helical wheel-driven pipeline robot system based on a high-strength spring-loaded wall device (see figure 1 ), which is characterized in that it includes a body mechanical structure and a control system; wherein, the body mechanical structure is composed of a screw head 1, a body 2 and a cage 3; the body 2 is the main body of the robot, and the screw head 1 and the cage 3 are installed on the fuselage 2; the screw head 1 is distributed and installed with driving wheels 4 in the circumferential direction; the cage 3 is distributed and installed with guide wheels 5 in the circumferential direction; the driving wheels 4 and The guide wheels 5 are connected to the screw head 1 and the cage 3 through the connecting rod 6 .

[0041] The screw head 1 is evenly distributed with three groups of driving wheels 4 in the circumferential direction, and the interval between each two groups of driving wheels 4 is 120° (see figure 1 ).

[0042] Each of the three groups of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com