Polyolefin blend composition and articles prepared therefrom

A technology of olefin copolymers and compositions, which is applied in the field of polyolefin blend compositions, and can solve problems such as damage to the transparency and blurring of molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The following examples illustrate the invention but are not intended to limit the scope of the invention.

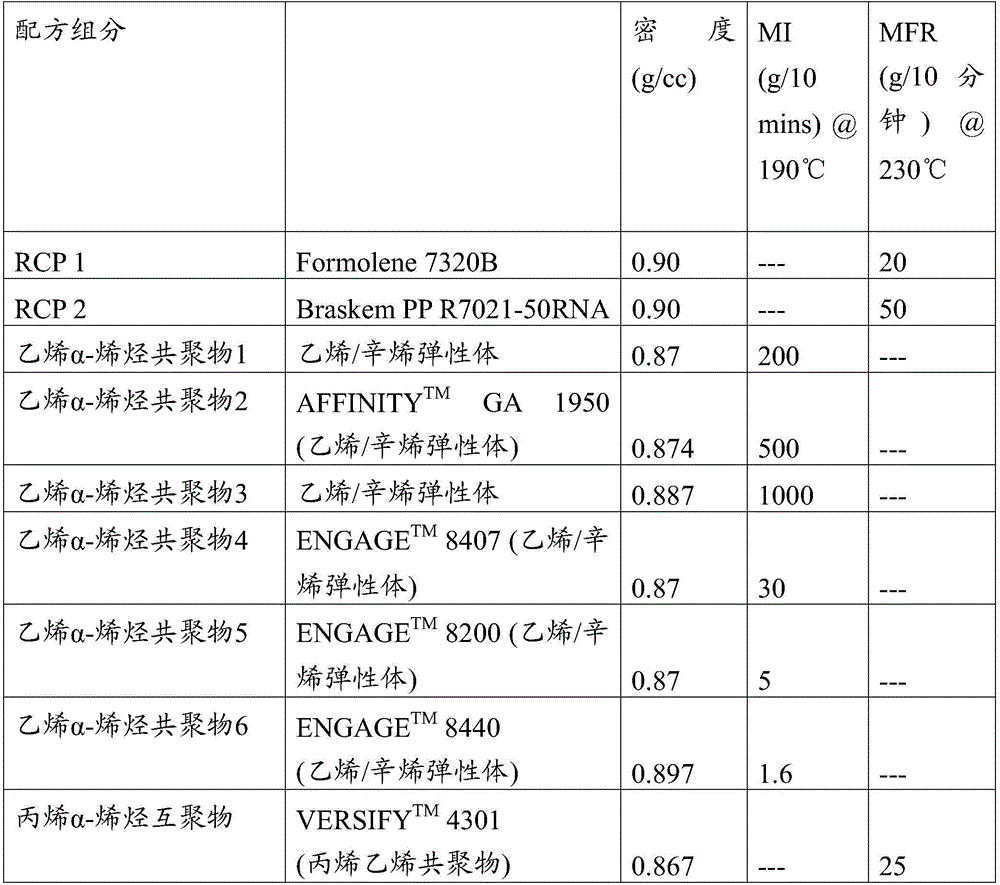

[0041] The formulation components are shown in Table 1.

[0042] Table 1

[0043]

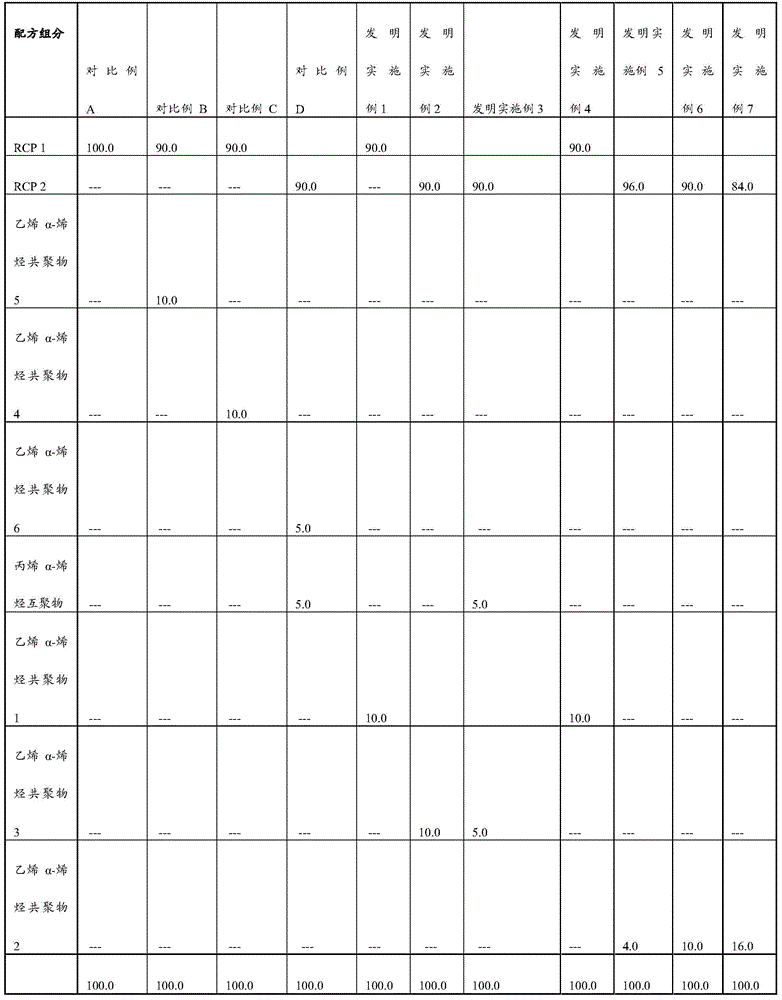

[0044] The formulation components shown in Tables 1 and 2 were dry tumble blended to form comparative blend compositions A-D and inventive blend compositions 1-7.

[0045] Table 2

[0046]

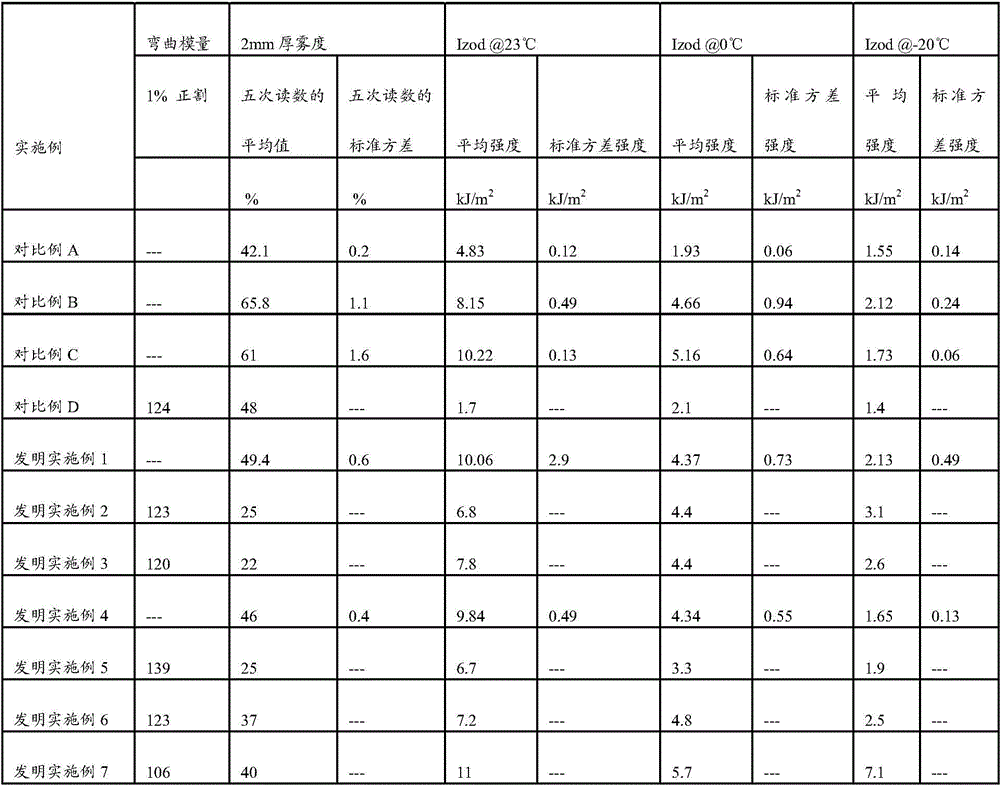

[0047] Comparative blend compositions A-D and inventive blend compositions 1-7 were respectively formed into injection molded samples, comparative examples A-D and inventive samples 1-7, based on the following method and the conditions shown in Table 3.

[0048] Comparative Blend Compositions A-D and Inventive Blend Composition 17 were injection molded using a Krasuss Maffei KM 110-390 / 390CL Injection Molding Machine equipped with a single shot mold base.

[0049] table 3

[0050] Barrel and mold temperature

Hopper area (℃)

30

Zone 1 temperature (℃)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com