Low-friction, abrasion resistant and easy-to-clean composite iron sole plate

A technology for irons and soleplates, applied in hand irons, washing devices, applications, etc., can solve problems such as burn marks, sticking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation of the sol is preferably as follows: non-aqueous (solid) pellets of base are added to the siloxane mixture and stirring is continued until the solid is completely dissolved in the liquid phase. Afterwards, the PMOH solution (pure water) was added dropwise to the solution while forcing the temperature in the container to not exceed room temperature. The color and transparency of the mixture can be adjusted by adding graphite and titanium dioxide as colorants (in a few ratios to each other), which will become transparent in nature when completed. These optional colorants can now be added to the mixture up to 15% by weight relative to the total solid matter. Mechanical stirring and ultrasonic baths can be used continuously in order to obtain a proper dispersion of the colorant in the liquid mixture.

[0039] This solution can be directly applied to the surface of the metal base plate that has been sandblasted and cleaned without an additional intermediate lay...

example 1

[0044] Example 1: Preparation of iron soleplate

[0045] The sol including the following components was mixed for about 12 hours.

[0046]

[0047] 1.07g H 2 O / 15g PMOH

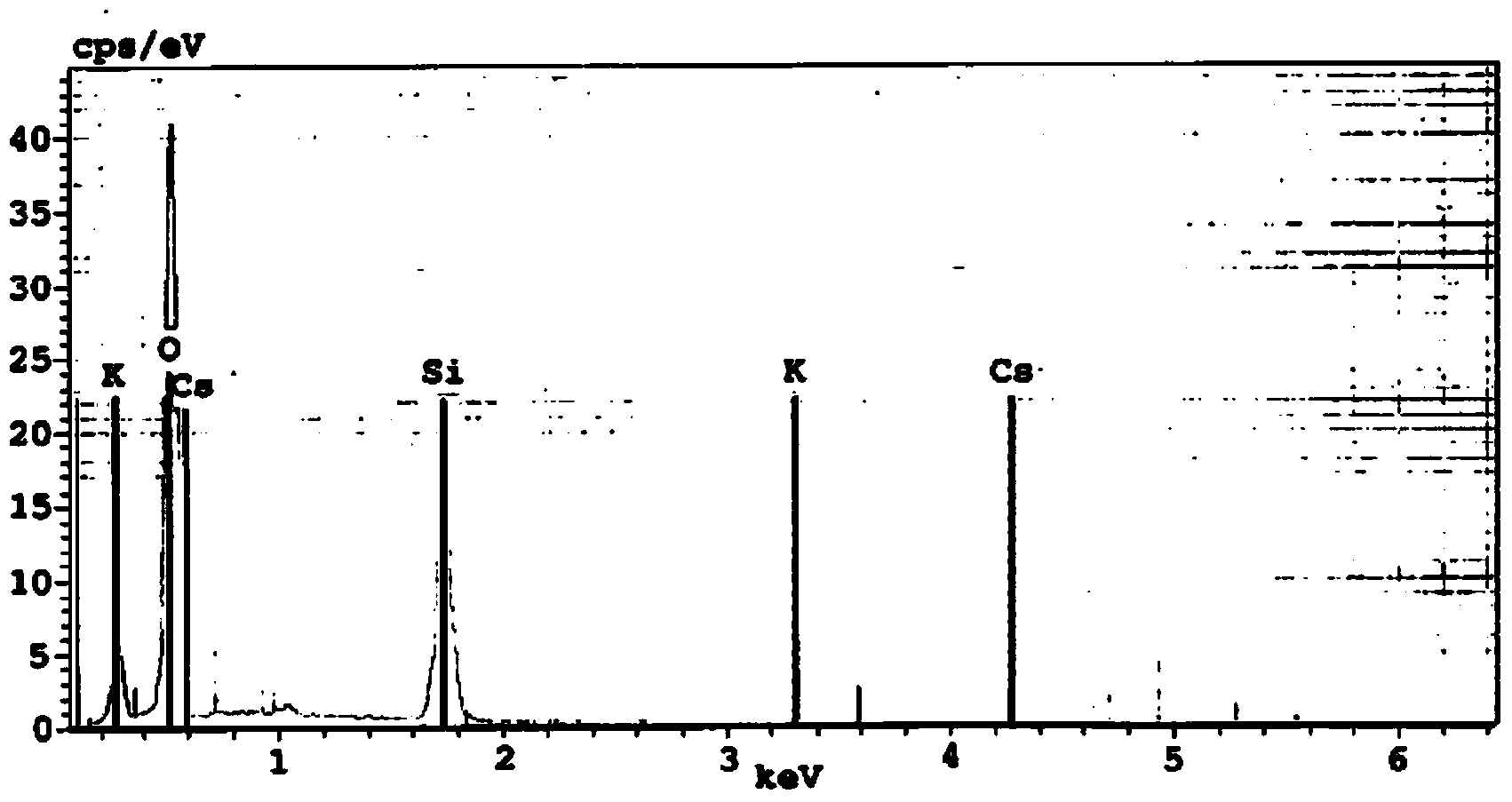

[0048] Next, add 1.01g TiO 2 And 0.34 g of graphite, and stirring the mixture for another few hours. By spraying, the mixture was applied to a sandblasted iron soleplate made of stainless steel. Next, the coated bottom plate was baked in an oven set at 400°C in a stepwise heating manner. Energy dispersive X-ray spectroscopy (EDX) was used to analyze the obtained coating, and the elemental composition of the sample included K, Cs and Si, as well as some desired oxides. figure 2 This analysis is shown.

example 2

[0049] Example 2: Wear test

[0050] A sample of the iron soleplate prepared according to Example 1 was processed using an abrasion test device (Elcometer 1720 washing durability abrasion tester), which used a Scotch Brite (ASTM D4213) to apply a pressure of 1.2 kg at 50 rpm for a total of 10,000 revolutions. Slight visible scratches were observed, and there was no visible peeling of the coating.

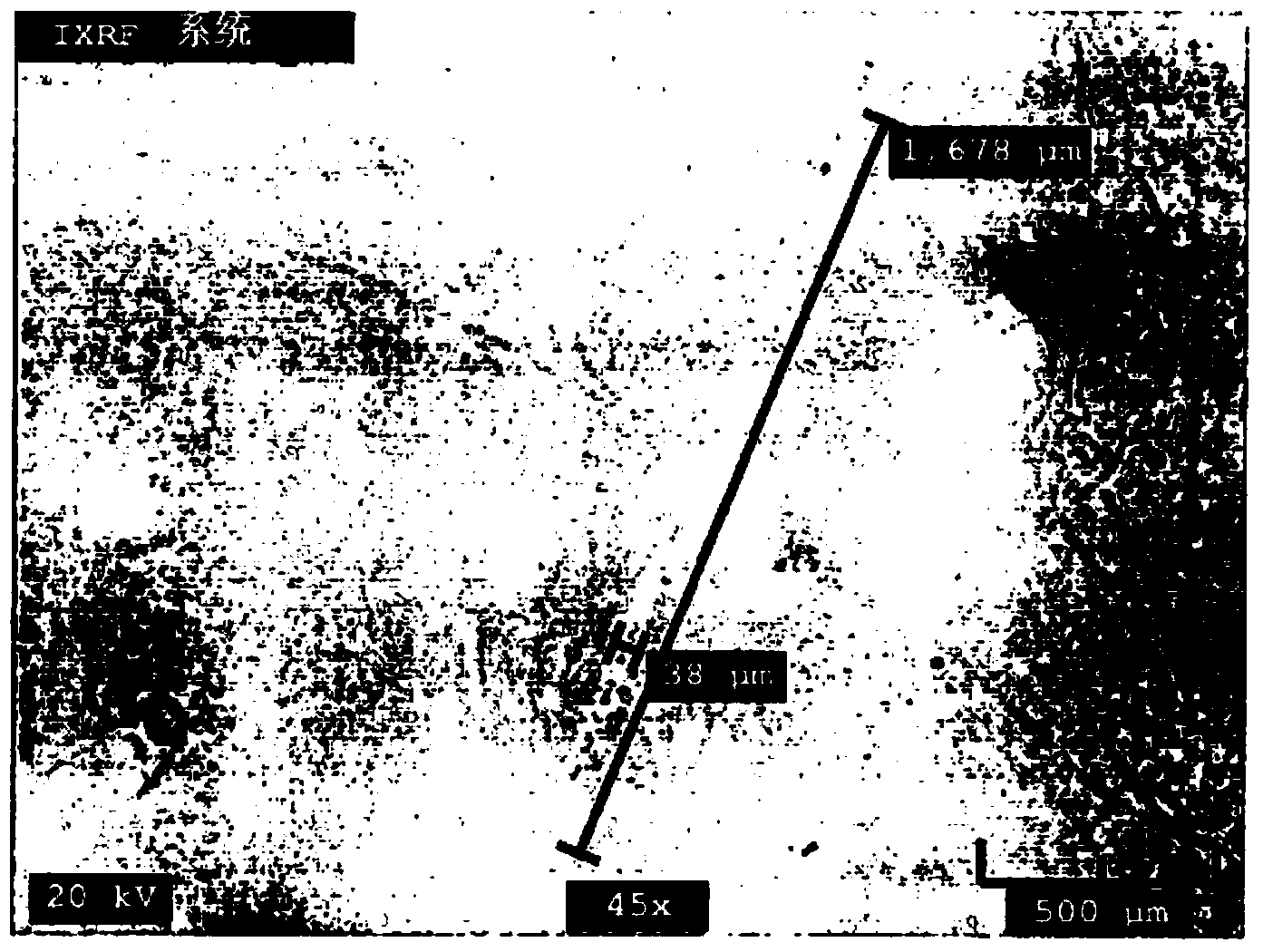

[0051] A scanning electron microscope was used to examine the base plate samples tested for wear characteristics. Figure 3a , 3b SEM images at different magnifications are shown in 3c and 3d.

[0052] Figure 3a The scratches that occurred in the abrasion test at 45x magnification are shown. The length and width of the scratch are approximately 1678 μm and 38 μm, respectively. The scratches are almost invisible to the naked eye.

[0053] Figure 3b Another scratched part at 100x magnification on the sample is shown. No extensive wear on the surface was observed, but small local deformat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com