Electric scab excision machine used for deep second degree burn

An electric and fuselage technology, which is applied in medical science, surgery, etc., can solve the problems that the grinder has no tool change function, unfavorable recycling, splash and residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

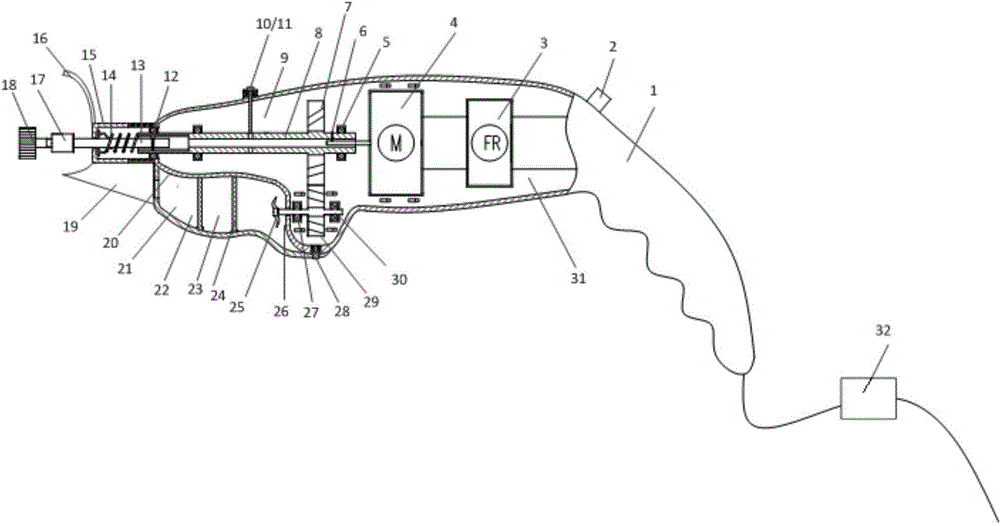

[0035] Such as Figure 1-Figure 3 As shown, the electric scab removing machine for deep second-degree burns includes a body 9, the rear part of the body 9 is an ergonomic handle 1, and a motor 4 is arranged inside the body 9, and the main shaft of the motor 4 passes through a pin 6 is connected with the hollow first transmission shaft 8, and the two ends of the first transmission shaft 8 are respectively supported by the first bearings 5 arranged inside the fuselage 9. There is a keyway on the inner hole of the first transmission shaft 8 and is connected with the second transmission shaft 13 through the pin shaft 12. The second transmission shaft 13 passes through the front end of the fuselage 9 and enters the sleeve 15 connected with the front end of the fuselage 9. The front end of the shaft 13 stretches out of the sleeve 15 and is connected with the collet type handle of a knife 17 , and the cutter 18 is installed on the collet type handle of a knife 17 .

[0036] The ha...

Embodiment 2

[0045] Embodiment 2 (do not provide accompanying drawing, can refer to Figure 1-Figure 3 ):

[0046] An electric scab-removing machine for deep second-degree burns, including a body 9, the rear part of the body 9 is an ergonomic handle 1, and a motor 4 is arranged inside the body 9, and the main shaft of the motor 4 is connected to the hollow body through a pin 6. The first transmission shaft 8 is connected to each other, and the two ends of the first transmission shaft 8 are respectively supported by the first bearings 5 arranged inside the fuselage 9 . There is a keyway on the inner hole of the first transmission shaft 8 and is connected with the second transmission shaft 13 through the pin shaft 12. The second transmission shaft 13 passes through the front end of the fuselage 9 and enters the sleeve 15 connected with the front end of the fuselage 9. The front end of the shaft 13 stretches out of the sleeve 15 and is connected with the collet type handle of a knife 17 , ...

Embodiment 3

[0053] Embodiment 3 (do not provide accompanying drawing, can refer to Figure 1-Figure 3 ):

[0054] An electric scab-removing machine for deep second-degree burns, including a body 9, the rear part of the body 9 is an ergonomic handle 1, and a motor 4 is arranged inside the body 9, and the main shaft of the motor 4 is connected to the hollow body through a pin 6. The first transmission shaft 8 is connected to each other, and the two ends of the first transmission shaft 8 are respectively supported by the first bearings 5 arranged inside the fuselage 9 . There is a keyway on the inner hole of the first transmission shaft 8 and is connected with the second transmission shaft 13 through the pin shaft 12. The second transmission shaft 13 passes through the front end of the fuselage 9 and enters the sleeve 15 connected with the front end of the fuselage 9. The front end of the shaft 13 stretches out of the sleeve 15 and is connected with the collet type handle of a knife 17 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com