Double wire underwater wet welding device and method

A technology of wet welding and welding equipment, applied in the field of twin-wire underwater wet welding equipment, which can solve the problems of reduced arc stability, thinner arc column, narrower weld width, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

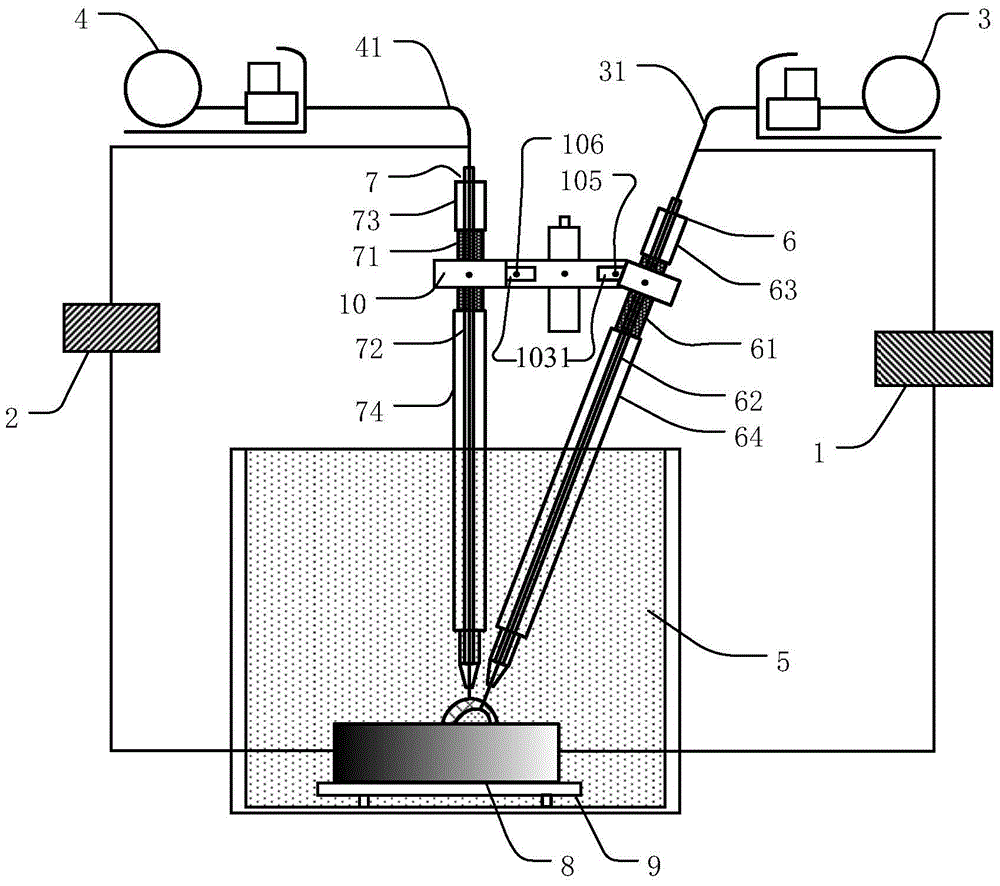

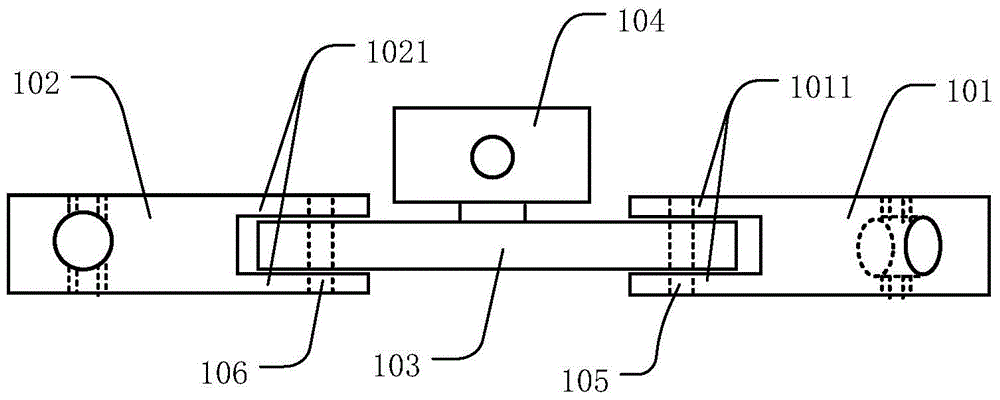

Embodiment 1

[0035] Such as Figure 4 As shown, in this embodiment, the angle α formed by the slave contact tip 75 and the welding workpiece 8 is 30-120°, for example, 50, 75, and 100 degrees, and the angle β formed by the main contact tip 65 and the welding workpiece 8 is 60-120°, such as 70, 90, and 110 degrees, and the distance H between the two contact tips is 15-30 mm, such as 15, 20, 25, and 30 mm, to ensure that the two welding wires form an elliptical molten pool.

Embodiment 2

[0037] Such as Figure 5 As shown, in this embodiment, the angle β formed by the main nozzle 65 and the welding workpiece 8 is 30-60 degrees, for example, 30, 40, 50, 60 degrees ( Figure 4 60°), the angle α formed by the slave contact tip 75 and the welding workpiece 8 is 90°, the main welding torch 6 uses solid-core welding wire, and the slave welding torch 7 uses flux-cored welding wire. At this time, the slave welding torch 7 vertically penetrates into the water , and use a larger welding current, such as 200A, 250A, 300A, which is conducive to the formation of a larger air bag, while the main welding torch 6 and the welding workpiece 8 form a certain angle, which mainly plays the role of filling metal and controlling the molten pool. In this way, the arc formed by the main welding torch 6 is inclined, while the arc formed by the secondary welding torch 7 is perpendicular to the welding workpiece 8. In this way, the two arcs acting on the same welding point not only increa...

Embodiment 3

[0039] Such as Image 6 As shown, since the main welding gun 6 and the slave welding gun 7 have the same structure, the difference from the second embodiment is that the main welding wire 3 and the slave welding wire 4 are interchanged in this embodiment, the main welding gun 6 adopts flux cored wire, and the slave welding gun 7 adopts solid welding wire. Core welding wire, wherein the main welding torch 6 uses a relatively large welding current, such as 200A, 250A, 300A, the arc formed by the main welding torch 6 is inclined, and the formed air bag is also inclined, which mainly plays the role of removing water, and is formed from the welding torch 7 The arc is vertical and mainly plays the role of filling metal and controlling the molten pool. Other steps, connection methods and implementation principles are the same as those in Embodiment 2.

[0040] The operating steps of the twin wire underwater wet welding method among the present invention are as follows:

[0041] Ste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap