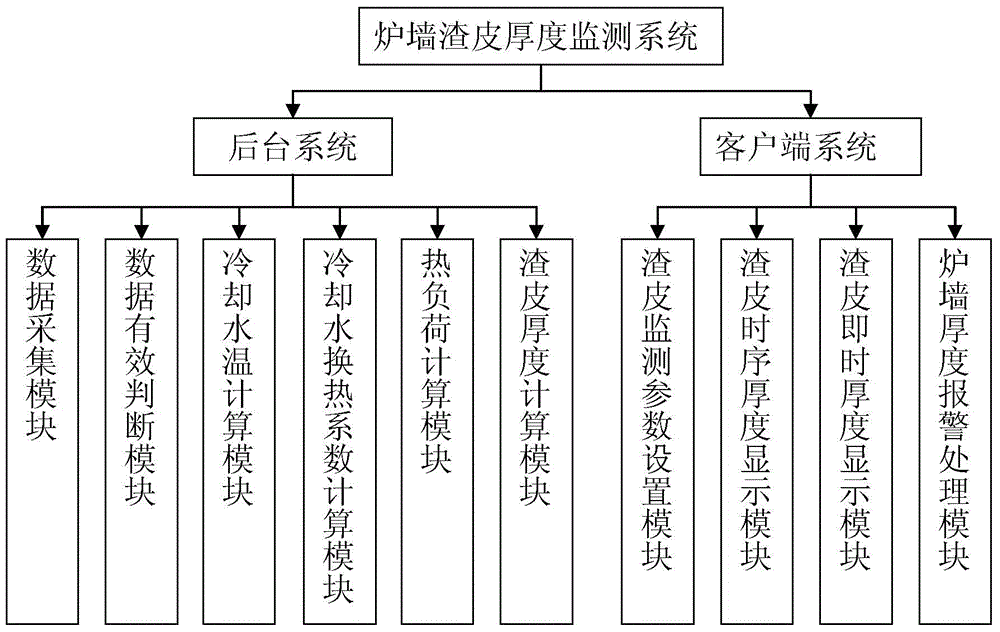

Blast furnace brickwork slag shell thickness monitoring system and method

A thickness monitoring and blast furnace technology, applied in inspection devices and other directions, can solve problems such as difficulty in obtaining, large differences in heat load, and lack of operability, and achieve the effect of extending service life and ensuring stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

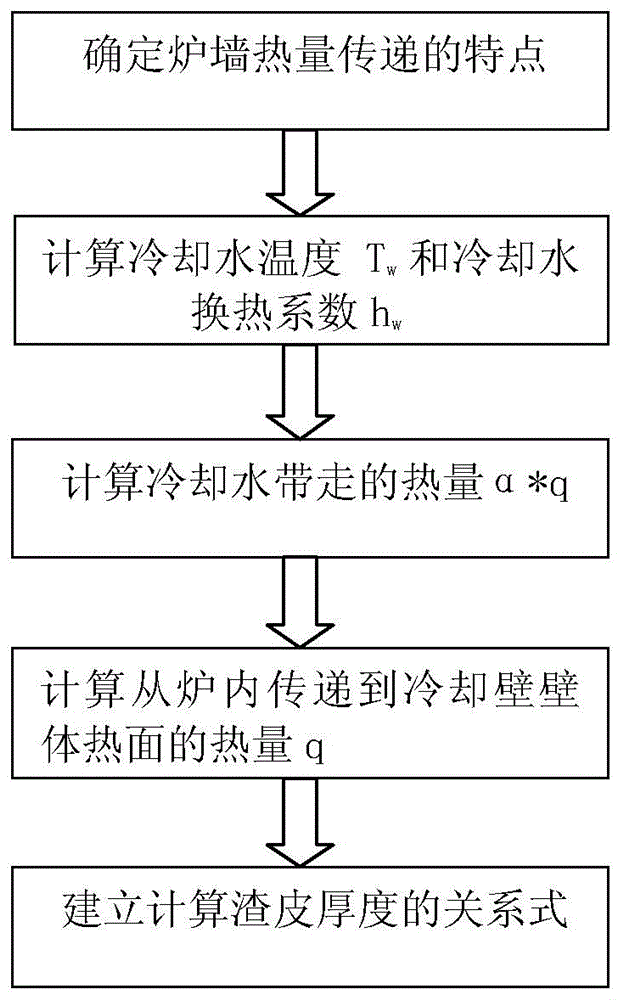

Method used

Image

Examples

Embodiment

[0051] The calculation method of this system is used to calculate the slag skin corresponding to a certain thermocouple on a certain piece of copper stave in B1 section of a domestic blast furnace bosh copper stave. Known conditions: about 85% (α=85%) of the heat transferred from the furnace is taken away by the cooling water, H1=0.6m, H=1.96m, and the equivalent diameter of the water channel d=0.0505m. L1=0.123m, L2=0.03m, L3=0.1m, λ s =380w / m.℃,λ b =15w / m.℃,λ z =1.2w / m.℃, Tz=1280℃. At a certain moment, the wall temperature Ts measured by a certain thermocouple of the cooling wall is 46°C, and the cooling water of the cooling wall Ts 进 =39℃, T 出 =42°C, area flow Q=161.5m3 / h (14 heads),

[0052] 1. Background calculation

[0053] 1) Judging the validity of the collected data

[0054] Judging that the collected thermocouple temperature and cooling water flow rate are within the normal range, you can use

[0055] 2) Cooling water temperature T w

[0056] According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com