Low-alloy-steel macroscopic fracture blue brittleness processing technology

A low-alloy steel, fracture blue brittle technology, applied in the field of steel fracture inspection, can solve the problem of fuzzy blue brittle effect and so on

Active Publication Date: 2015-03-11

SHANXI TAIGANG STAINLESS STEEL CO LTD

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For a long time, experimenters can only achieve the blue crisp effect through years of experience and increasing the amount of experiments. Even so, it is unclear what the best blue crisp effect should be

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

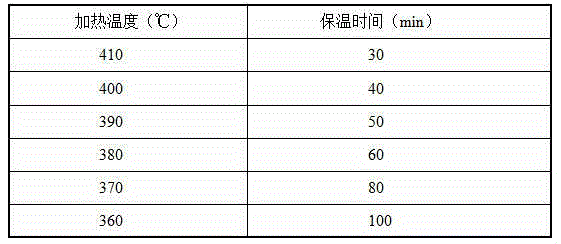

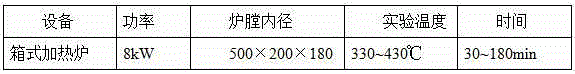

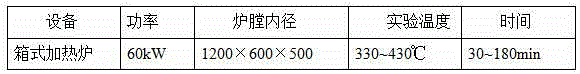

[0034] 1. Heat treatment process test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A disclosed low-alloy-steel macroscopic fracture blue brittleness processing technology comprises performing heat treatment on an entrusted sample, performing machine tooling and press breaking, and then performing blue brittleness processing. The heat treatment technology for low-alloy-steel fracture blue brittleness is exploited. The heating temperature, the warm-keeping time, the putting method, the heating equipment and structure morphological analysis are determined, and the blue brittleness effect reaches an optimum state, thereby improving the accuracy for grading macroscopic inclusions.

Description

technical field [0001] The invention relates to a low-magnification fracture brittle process method of low-alloy steel, which belongs to the technical field of steel fracture inspection. Background technique [0002] Steel-iron-testing standard (SEP 1584): Blue brittleness test is to detect the presence of non-metallic impurities on the cross-section of deformed steel products. These impurities can be seen without magnifying tools (length > 1.5mm, width > 0.05mm) , heating it to the blue-temper color at about 330° C. in the temperature range of the blue-temper color. [0003] The national standard only provides the theoretical blue embrittlement temperature, but the heat treatment process and blue embrittlement effect are not described in detail. For a long time, experimenters can only achieve the blue crisp effect through years of experience and increasing the amount of experiments. Even so, it is unclear what the best blue crisp effect should be. In order to meet t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D11/00C21D6/00G01N21/25

Inventor 马建宏贾元伟王伟冯宝贵

Owner SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com