A road surface preventive maintenance method for degrading automobile exhaust

A preventive maintenance and vehicle exhaust technology, which is applied to the condensing pavement, roads, roads and other directions paved on site, can solve the problems of inability to fully decompose toxic gases, reduce the anti-skid performance of asphalt pavement, endanger driving safety and other problems. Realize the effect of large-scale long-distance construction, convenient and simple construction, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

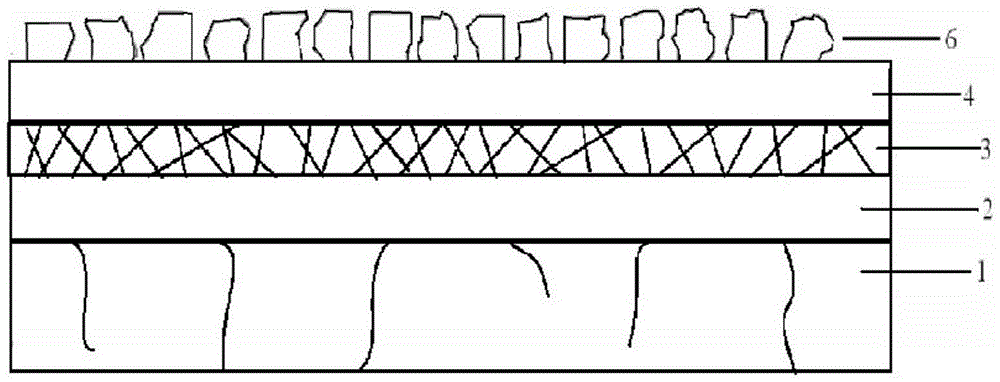

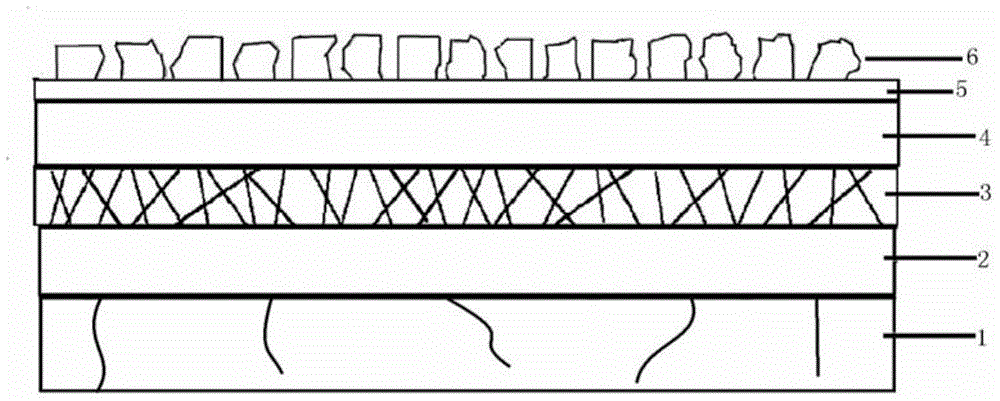

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] The structure of the fiber-added synchronous gravel sealing vehicle in the present invention is based on the structure of the multi-purpose synchronous gravel sealing vehicle in patent 201220601217.4, and two sets of titanium dioxide are arranged on both sides of the multi-purpose synchronous gravel sealing vehicle Solution nozzles, one group on the left and one on the left. The nozzles are set between the crushed stone spreader and the rear asphalt nozzles of the asphalt fiber spreader. The titanium dioxide solution nozzles are arranged at equal intervals, and the number is consistent with the number of asphalt nozzles to ensure that the titanium dioxide solution is spread evenly.

[0028] A road surface preventive maintenance method for degrading automobile exhaust gas, comprising the following steps:

[0029] 1) Before paving, debug the fiber-added synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com