Safe fast connecting mode and safe fast connector

A fast connection and safe technology, applied in the direction of earthwork drilling, surveying, drilling equipment, etc., can solve the problems of inability to disassemble, loose, damage, etc., and achieve the effect of firm and reliable structure, avoiding failure forms, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

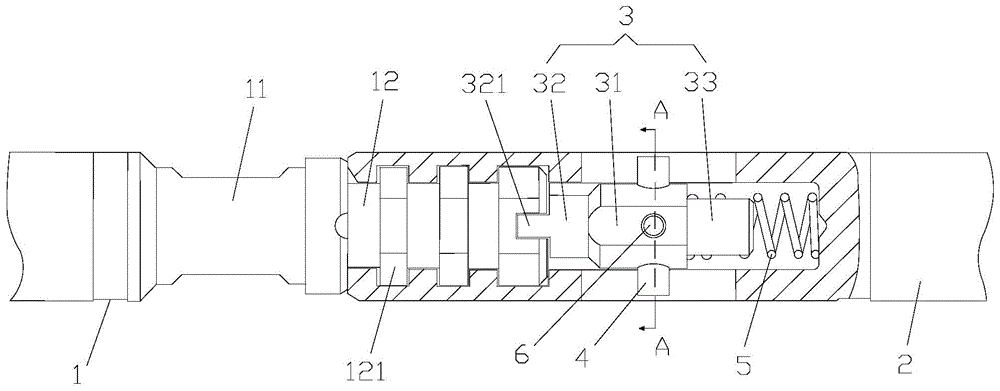

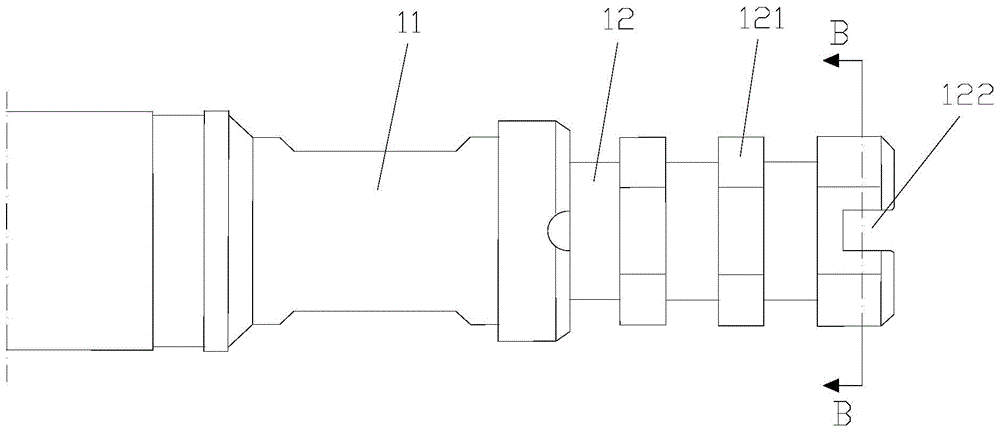

[0026] The safe and quick connection method of Embodiment 1 of the present invention is applied to a weighted rod, wherein the weighted rod is used to provide the weight required for operation, so that the tool string can fall against the pressure acting on its section and the resistance of the packing box; Rods are the most common type and are manufactured from solid round steel.

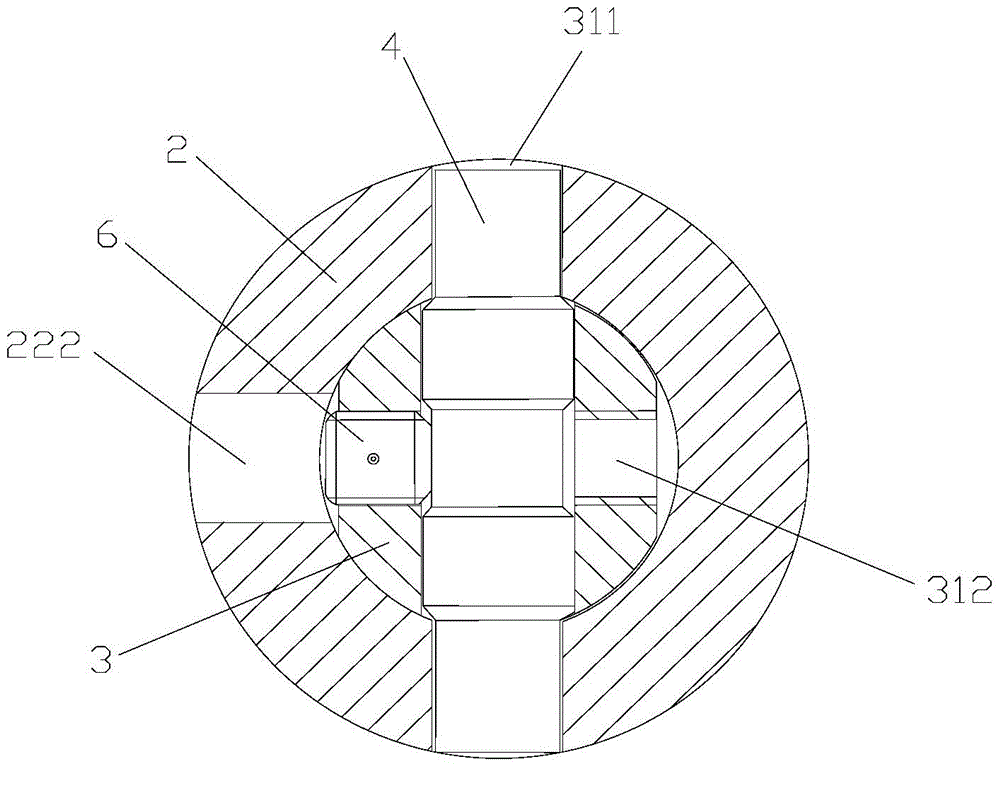

[0027] The common weighted rod is integrally formed with the male and female joints and the weighted rod; the two ends of the common weighted rod are respectively provided with male and female joints to ensure the safe and reliable connection between the weighted rod and the tool string. The combination of the slider and the spring is movably inserted into the pin along the radial direction of the slider, and then the pin and the slider are locked and fixed by screws.

[0028] The ordinary weighted rod in Example 1 of the present invention adopts the above-mentioned safe and quick connection method...

Embodiment 2

[0030] The safe and fast connection method of Embodiment 2 of the present invention is applied to chain jars; among them, many steel wires and wire ropes are used for downhole tool strings, and it is often necessary to cut off pins during the fishing process of downhole devices, or Very strong strength is needed when salvaging the downhole device, and it is far from enough to only rely on the pulling force of steel wire or steel wire rope, and it can only be completed by the shock force of the jar. The chain jar is a kind of jar, which is also called a mechanical jar. It uses the instantaneous gravity of the connecting rod to transmit the effective jarring force through the lifting and lowering of the steel wire on the ground. The design of its main and auxiliary chains is based on a Telescopic opening chain effect; the chain jar has a simple structure and can shock up and down, and is the most commonly used jar.

[0031]The main chain of the chain jar is integrally formed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com