Variable structure type C type LNG (liquefied natural gas) liquid tank oscillation test system

A liquid tank sloshing and test system technology is applied in the field of marine engineering LNG/LPG storage and transportation, which can solve the problems of quantity and form research, non-disassembly, non-discussion, etc., to achieve the convenience of research, installation and efficiency improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structure of the present invention will be further described below with reference to the accompanying drawings.

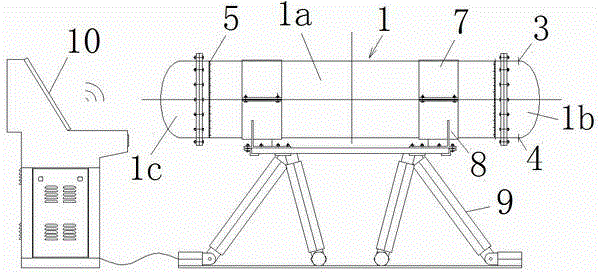

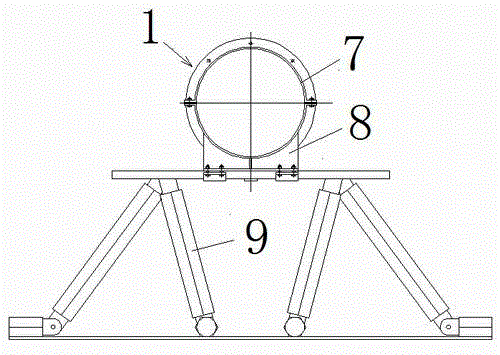

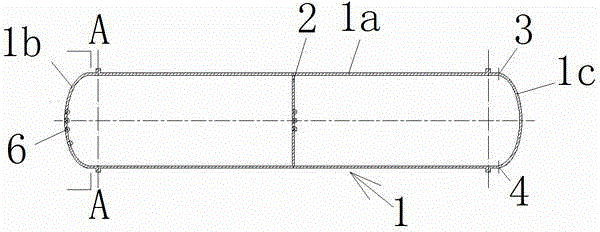

[0023] figure 1 , 2 It shows a front view and a left view of a variable structure C-type LNG liquid tank sloshing test system. The system is composed of test tank body 1, swash bulkhead 2, pressure sensor 6, semicircular collar 7, base 8 and other parts. The main tank body 1a, the first head 1b, the second head 1c and the swash bulkhead 2 are made of polymethyl methacrylate to better observe the change of the free liquid level in the tank. The semicircular collar 7 and base 8 are made of steel. The semicircular collar 7 and the base 8 are connected by bolts to fix the test tank body and facilitate disassembly. The main tank body 1a, the first head 1b, and the second head 1c are connected in the form of flanges, and the flange is integrated with the main tank body 1a, which is convenient for replacing the head forms at both ends of the test tank body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com