Temperature control method for continuous casting billet induction heating process, based on iterative learning control

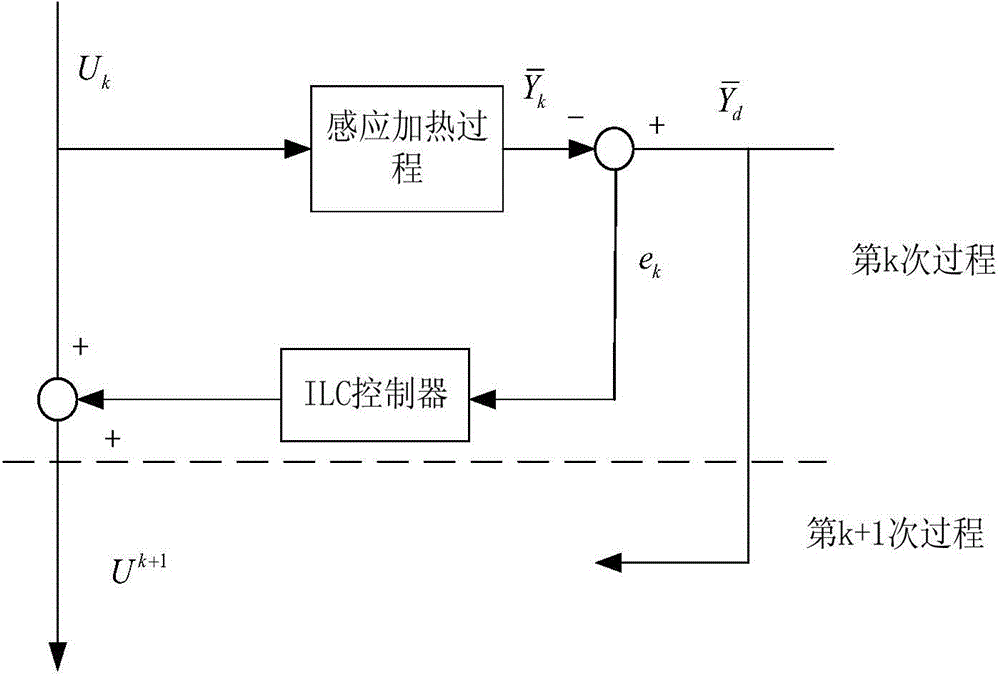

It is an iterative learning control and induction heating technology, which is applied in the direction of using electric mode for temperature control. It can solve the problems of relying on prediction models, poor control effect, and insufficient anti-interference ability of models, so as to suppress model mismatch and various disturbances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. The following implementations are only used to illustrate the present invention, but not to limit the scope of the present invention.

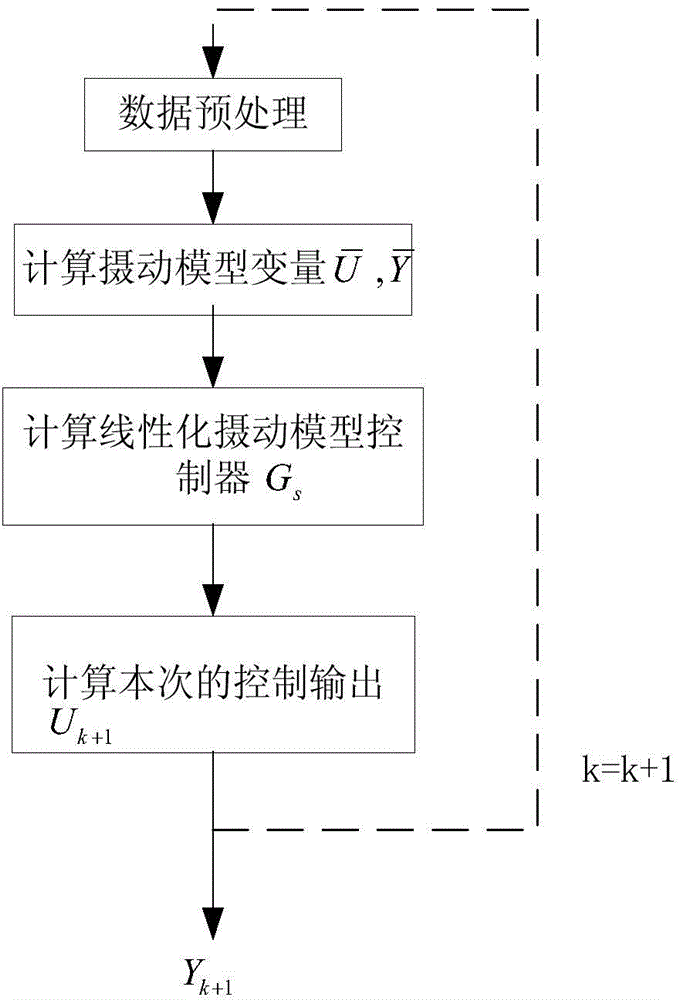

[0023] Such as figure 2 Shown, the inventive method comprises the following steps:

[0024] 1. Data preprocessing

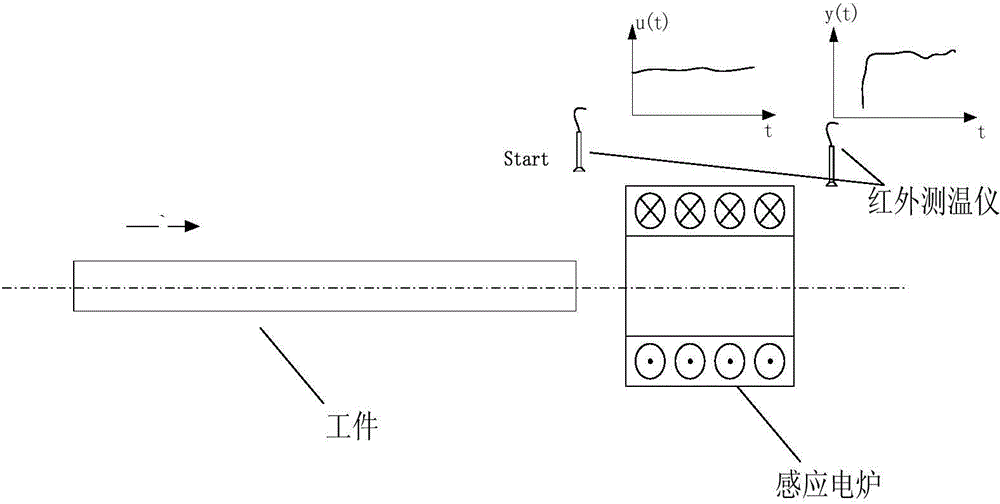

[0025] There are k process data in the historical database, from which the following data trajectories are obtained: intermediate frequency power supply control voltage U, billet inlet temperature R, and billet outlet temperature Y, where U is the input trajectory and Y is the output trajectory. The specific preprocessing steps are as follows:

[0026] Step 1-1: There is a temperature sensor at the entrance and exit of the induction furnace. The inlet temperature threshold is set to 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com