Intelligent management system for FMS (Flexible Manufacture System) cutters based on two-dimensional technology

A tool management and two-dimensional code technology, applied in the field of flexible manufacturing systems, can solve the problems of high cost of RFID tags, large number of tools, and difficulty in popularization and application, and achieve the effect of large storage capacity, low cost, and strong damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

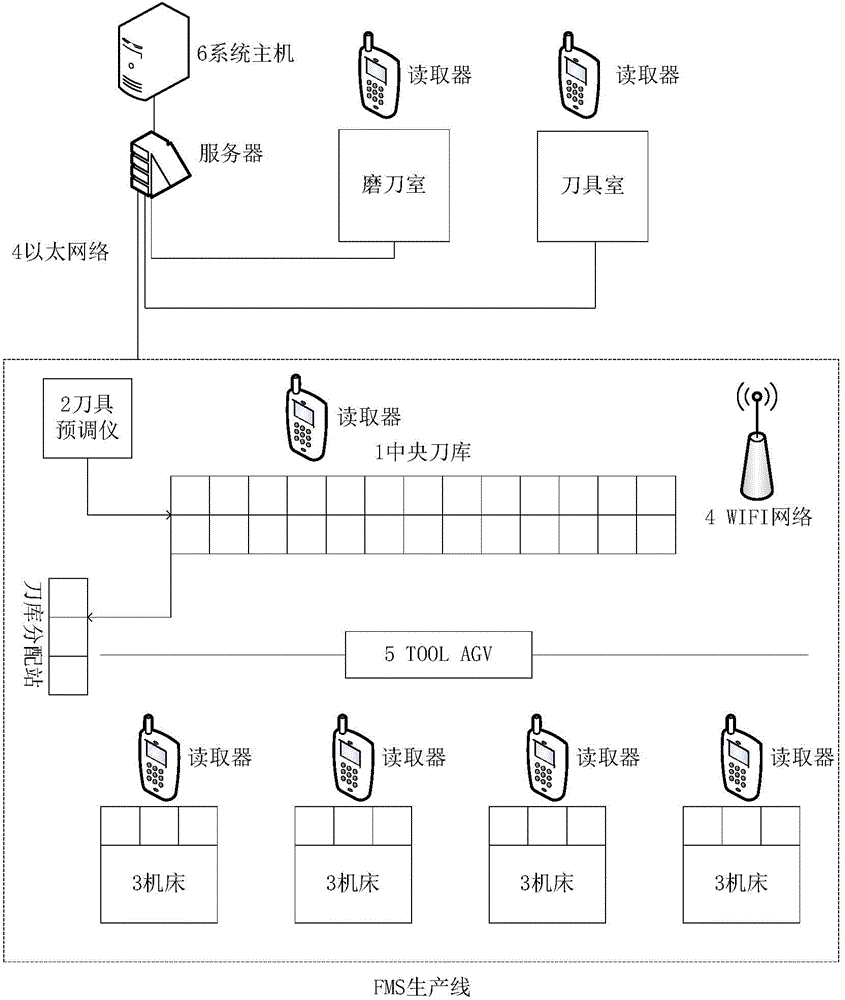

[0015] The FMS tool intelligent management system based on two-dimensional code technology involved in this embodiment includes a central tool magazine 1, a tool presetter 2, a machine tool 3, a workshop local system 4, a tool delivery device 5, and a tool management computer 6, wherein The central tool magazine 1 includes a combination tool provided with a two-dimensional code label and a tool holder equipped with a two-dimensional code reading device; the tool presetter 2 is used to adjust the assembled tool or the ground tool before the tool is put into storage. The tool is pre-adjusted; the machine tool 3 is equipped with a two-dimensional code reading device; the workshop local area system 4 covers each workshop local area network, and whenever the tool status information changes, the information will be fed back and notified to the central tool magazine and FMS production line in time Tool management system; the tool conveying device 5 is responsible for tool delivery; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com