Solder resist ink circuit board manufacture method

A production method and technology of solder resist ink, applied in the manufacture of printed circuits, applying paste/ink/powder resists, printed circuits, etc., can solve the problem of easily exceeding the thickness requirements of solder resist inks, failing to meet production needs, ink thickness, etc. Height difference and other problems, to achieve the effect of uniform thickness, high degree of automation and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

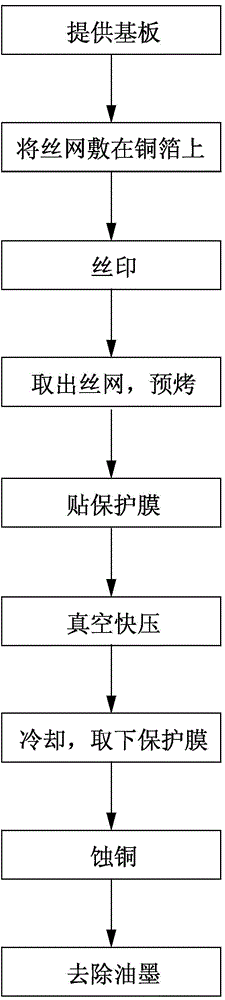

[0021] Such as figure 1 As shown, the present invention provides a kind of manufacture method of solder resist ink circuit board, comprises the following steps:

[0022] Step (1): providing a substrate, the substrate is provided with copper foil;

[0023] Step (2): Lay the screen on the copper foil of the substrate, the screen is provided with mesh holes, and the distribution of the mesh holes corresponds to the circuit pattern;

[0024] Step (3: silk screen printing, apply the ink on the screen, the ink flows from the mesh of the screen to the surface of the copper foil, forming an ink pattern on the surface of the copper foil, corresponding to the circuit pattern;

[0025] Step (4: Take out the screen, put the substrate into a baking machine, and pre-bake it so that the ink on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com