Novel woodworking drilling machine convenient for operation

A woodworking drilling technology that is easy to operate and is applied to fixed drilling machines, wood processing equipment, and manufacturing tools. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

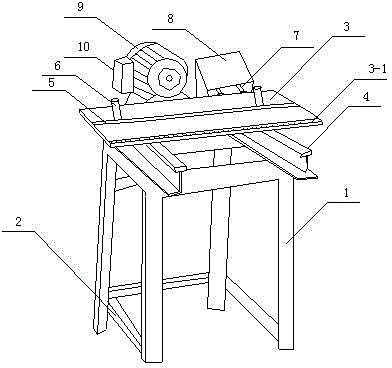

[0015] Embodiment 1: a plank with a width of 1 meter is placed on the workbench 3, the positioning pin bolt 6 is used to slide on the chute 5, the plank is fixed and positioned, the working motor 9 is turned on, and the plank is drilled with a drill bit 10, and the drill bit 10 is used to drill the plank. The waste debris produced by the hole is cleaned into the waste collection box 8 by the cleaning tool. When the length of the plank needs to be measured, it can be measured by placing it on the side of the scale layer 3-1, and the workbench 3 is slidably connected with the track 4, which can Adjust the distance between the workbench 3 and the drill bit 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com