Automobile decorating plate

A car decoration and mixing technology, applied to vehicle parts, transportation and packaging, superstructure, etc., can solve the problems of reduced use effect, deformation, and odor emission, and achieve the effect of improving the strength index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

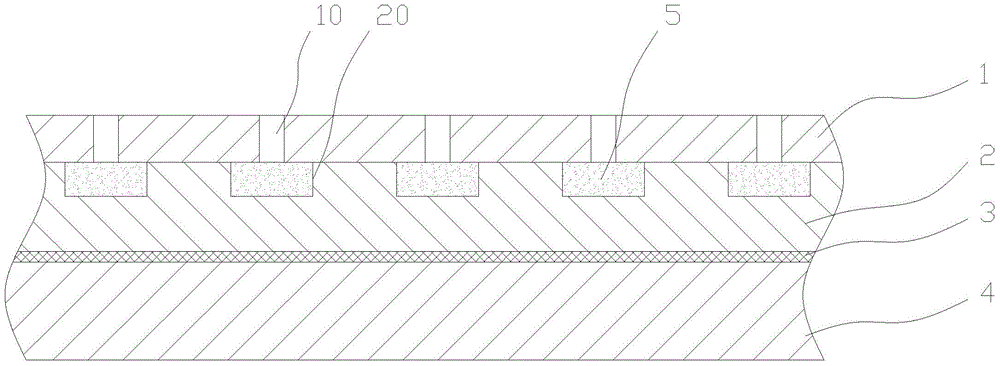

[0010] The present invention as figure 1 As shown in -5, it includes successively a corium layer 1, a mixing layer 2, a metal mesh 3 and a mixing layer 2 4; the added metal mesh can effectively improve the strength indicators of the automotive decorative panel; the leather layer 1 A plurality of through holes 10 are provided on the top, and a plurality of accommodating grooves 20 are provided on the end surface of the mixing layer-2 facing the corium layer, the through holes 10 are coaxial with the accommodating grooves 20, and the through holes The inner diameter of 10 is smaller than the inner diameter of the containing tank 20; the containing tank 20 is provided with coumarin 5.

[0011] Coumarin, also known as difuran ring and oxinone, is an important spice, naturally occurring in black coumarin, snakewort, wild vanilla, orchid; and can be obtained through salicylaldehyde and ethyl Anhydrides are prepared under the action of sodium acetate. The smell of coumarin is sweet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com