Electrolytic copper foil, flexible circuit board and battery

A technology of electrolytic copper foil and battery, which is applied in the direction of circuits, battery electrodes, printed circuit components, etc. It can solve the problems of low profile of the precipitation surface, inability to have both flexibility and rigidity, and achieve improved anti-rust function and chemical resistance Quality, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9、 comparative example 1~8

[0107] The manufacturing conditions such as electrolyte composition are shown in Table 1. The copper sulfate electroplating solution with the composition shown in Table 1 was cleaned through an activated carbon filter, and then the additives shown in Table 1 were added to prepare a specific concentration.

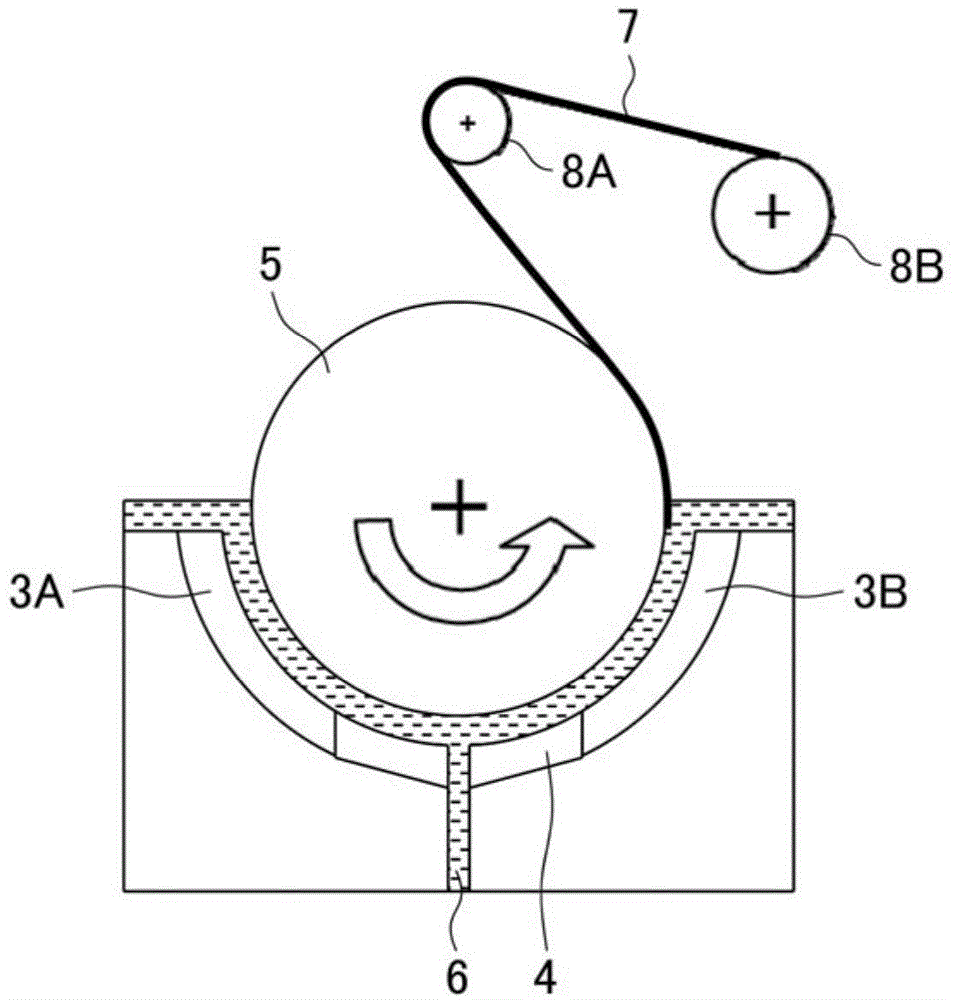

[0108] Will figure 2 The first anode 3 shown and the second anode 4 are adjusted to the current density and the anode length shown in table 2, using the same figure 2 The rotary drum foil-making device shown in the figure produces electrolytic copper foil with a thickness of 12 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com