Novel corundum smelting furnace

A smelting furnace and corundum technology, applied in the field of new corundum smelting furnaces, can solve problems such as low reliability, high power consumption, and slow production rhythm, and achieve the effects of fast production rhythm, low power consumption, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

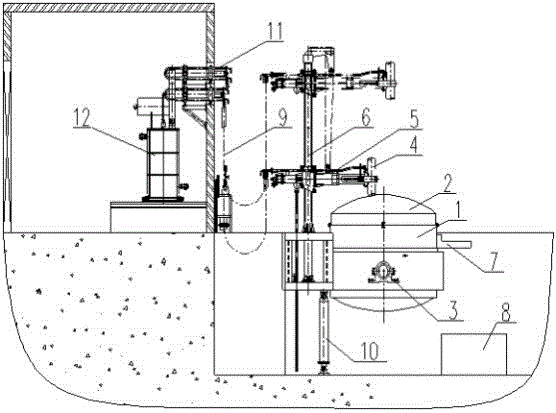

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0014] This embodiment is a new corundum smelting furnace for the field of corundum smelting.

[0015] 1. The furnace body 1 is seated on the tilting frame 3 with the tilting oil cylinder 10 at the bottom. When the tilting oil cylinder 6 works, the furnace body 1 tilts at a certain angle, and the liquid material flows out from the discharge chute 7 to the finished package 8 . At this time, the electrode 4 is inserted and heated by electricity, so that the heating and smelting time of the latter furnace is shortened, power consumption is saved, and productivity is improved.

[0016] 2. The structure of the furnace cover 2 is simplified, no water is needed, and the safety is increased. The inner lining of the furnace cover 2 adopts refractory fiber, thereby reducing the weight of the furnace cover and preventing the collapse of the furnace cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com