A fault-tolerant low-power scheduling method suitable for CNC systems

A scheduling method and technology of numerical control system, applied in the direction of response error generation, multi-programming device, etc., can solve the problem of ignoring dynamic idle time, etc., and achieve the effect of increasing cost, increasing heat generation, and reducing running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

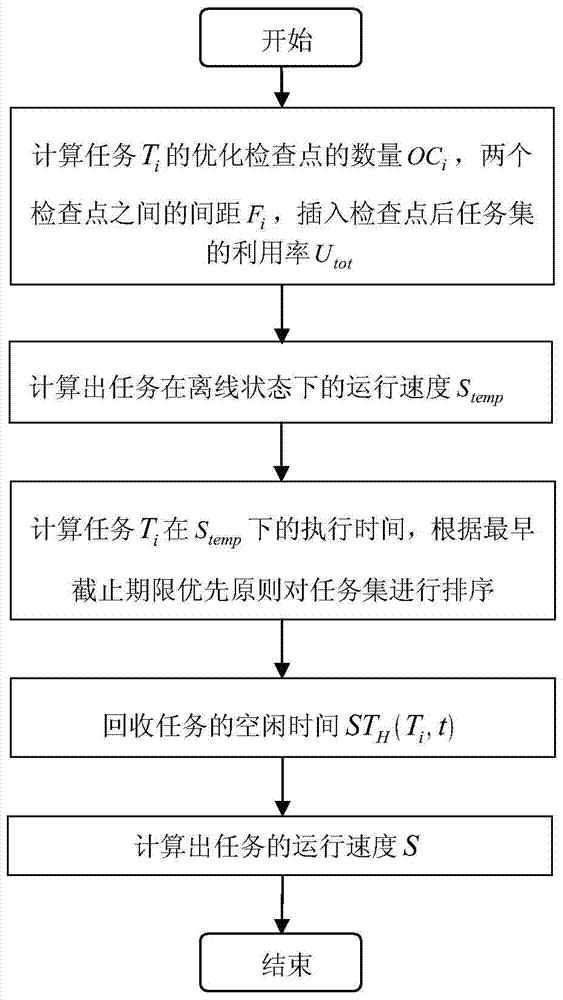

[0040] see attached figure 1 , 2 , 3, is a fault-tolerant low-power scheduling method suitable for the CNC system cycle, including the following steps:

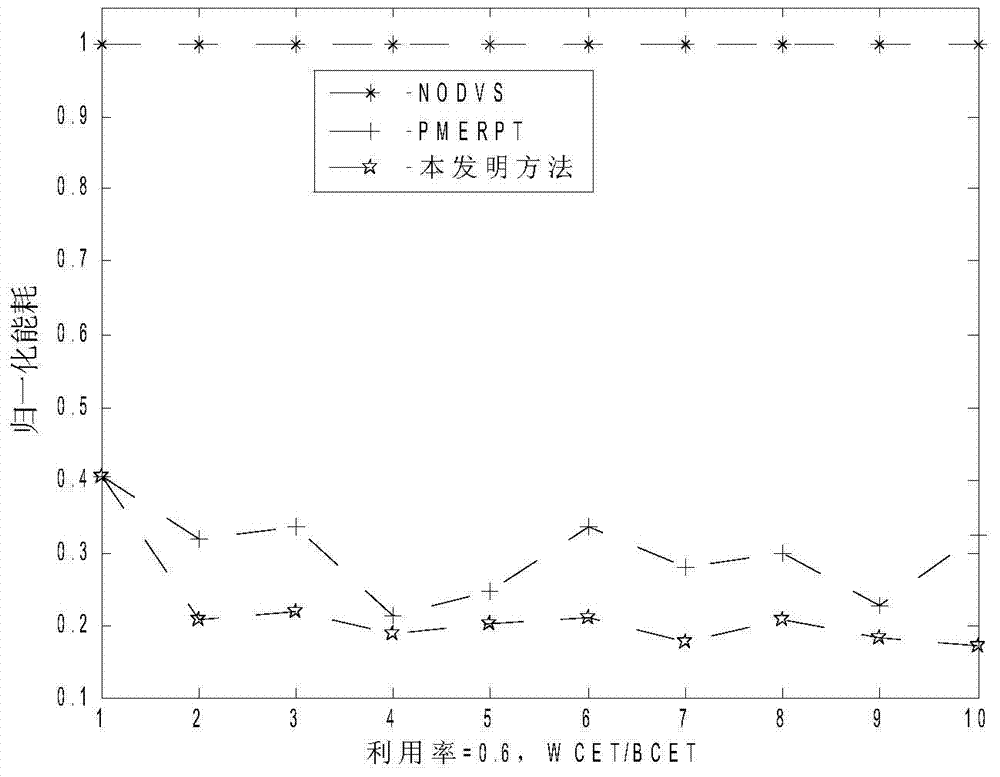

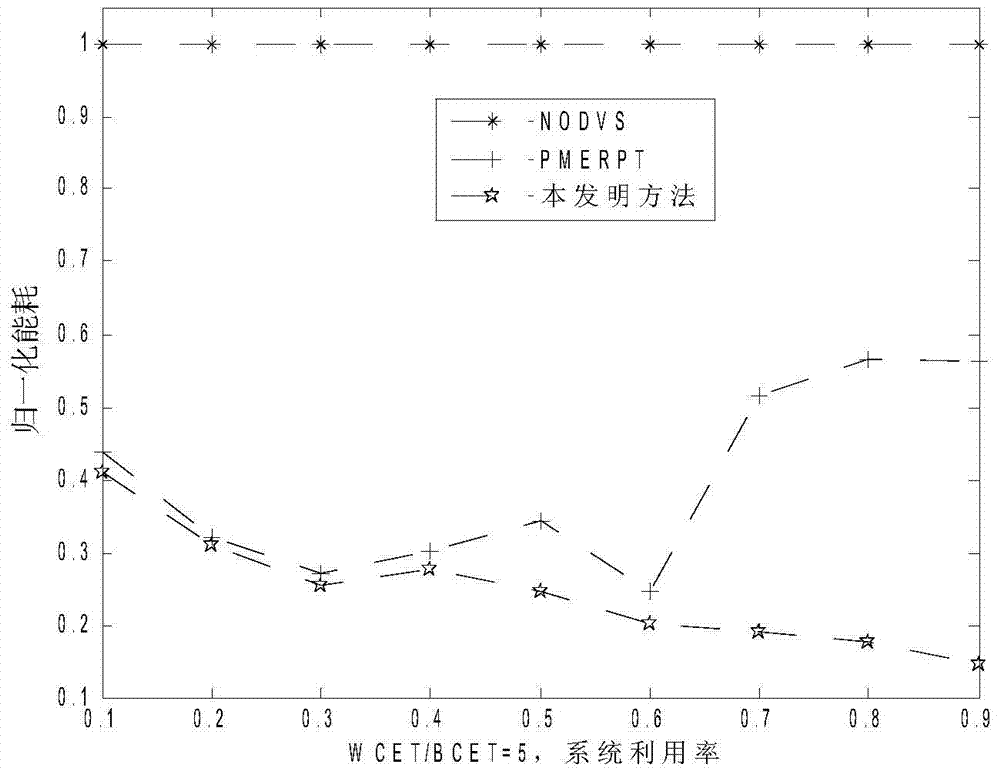

[0041] Before task set scheduling, compute task T i The number of optimized checkpoints OC i , the spacing F between the two checkpoints i , and the utilization U of the task set after inserting the checkpoint tot ; Calculate the running speed S of the task in the offline state temp ; compute task T i in S temp The task set is sorted according to the earliest deadline priority principle; when a task is completed, the idle time ST of the task is reclaimed H (T i , t), using the idle time ST H (T i , t) to calculate the running speed S of the task.

[0042] The present invention is further described:

[0043] Computational task T i The number of optimized checkpoints OC i , the spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com