Insulation assembly for nuclear fusion reactor

A technology for insulating components and reactors, which is used in thermonuclear fusion reactors, fusion reactors, nuclear reactors, etc., can solve the problem of not having insulating components, and achieve the effect of satisfying the wall treatment effect, high degree of insulation, and reliable technical guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

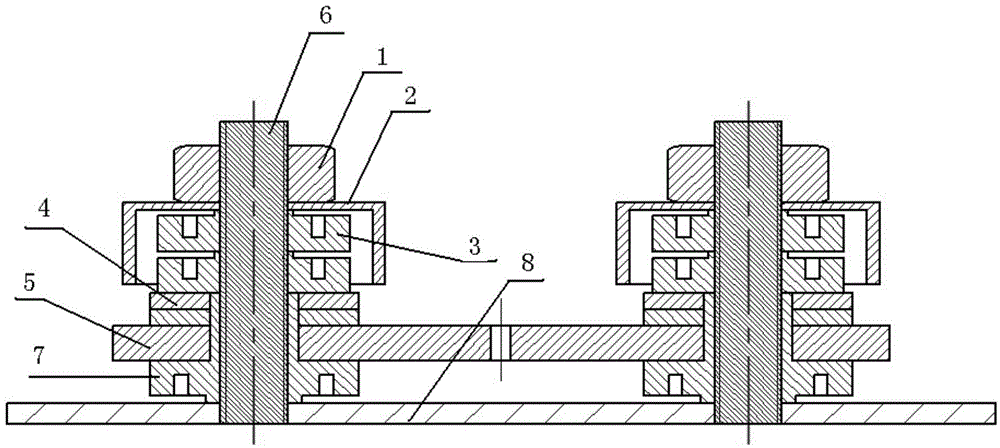

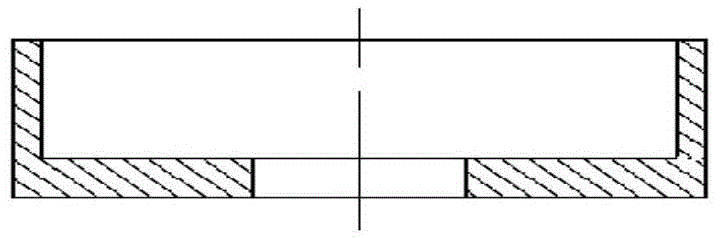

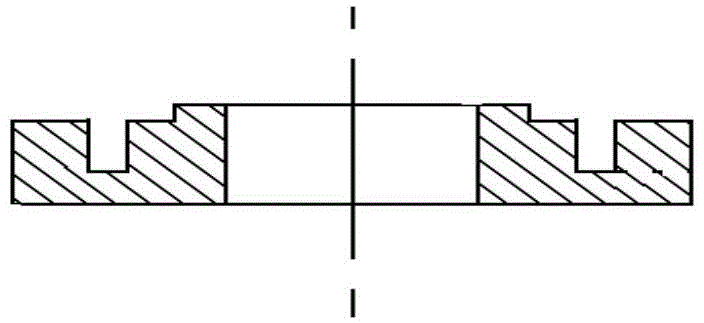

[0020] An insulating assembly provided by the present invention includes a nut 1, a cap 2, a concave-convex concentric ring washer 3, a flat concentric ring washer 4, an electrode fixing plate 5, a fixing bolt 6, and a sleeve-shaped concentric ring washer 7 and the wall 8 of the vacuum chamber, wherein the fixing bolt 6 is welded on the wall 8 of the vacuum chamber, and a sleeve-shaped concentric ring washer 7 is installed on the fixing bolt 6, and the sleeve-shaped concentric ring washer 7 is the outer surface A sleeve structure in the shape of a stepped shaft along the axial direction, including a stepped shaft section with a larger outer diameter at the lower end and a stepped shaft section with a smaller outer diameter at the upper end. The wall 8 of the vacuum chamber is in contact with, the upper end of the smaller outer diameter stepped shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com