Resistance slurry used for thick film circuit and based on ceramic tile and preparation process thereof

A technology of thick film circuit and resistance paste, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of difficulty in maintaining the normal operation of the heating system, waste of resources, large initial investment, etc., and achieve excellent thixotropy and anti-settling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

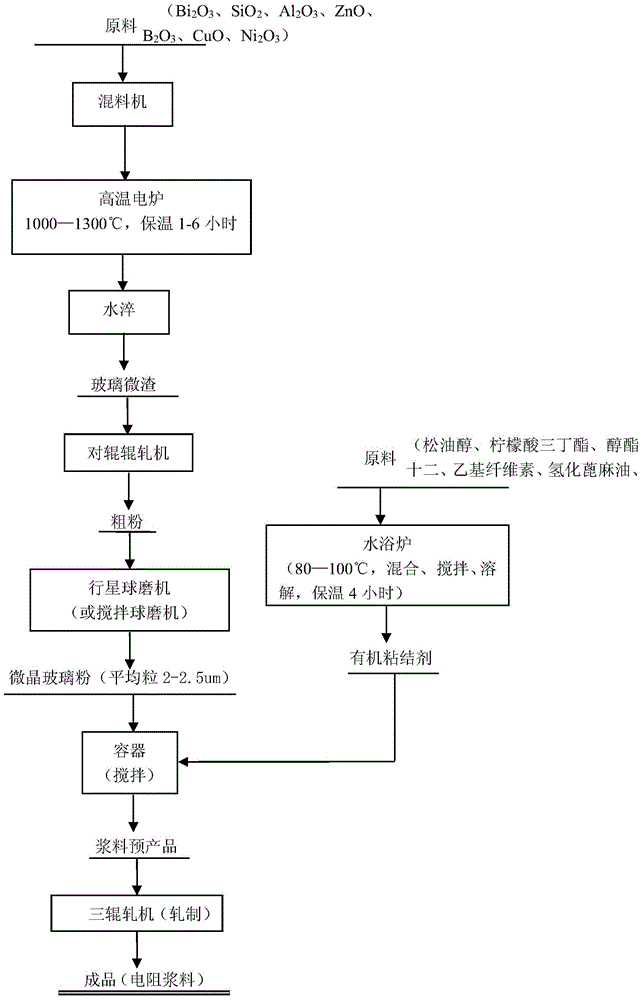

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of glass-ceramic powder, composition and weight percentage of glass-ceramic powder: Bi 2 o 3 62%, SiO 2 5%, Al 2 o 3 7%, ZnO3%, B 2 o 3 15%, CuO4%, Ni 2 o 3 10%; the above composition is placed in a high-temperature electric furnace, the melting temperature is 1000 ° C, and the temperature is kept for 3 hours. After water quenching, the coarse powder is obtained by rolling with a pair of rollers, and then finely ground by a planetary ball mill or a stirring ball mill to obtain an average particle size of 2 - 2.5 microns, glass-ceramic powder with a maximum particle size not exceeding 11 microns for use;

[0023] (2) The preparation and dissolution process of the organic binder, the composition and weight percentage of the organic binder:

[0024] Terpineol 65%, tributyl citrate 18%, alcohol ester twelve 7%, ethyl cellulose 5%, hydrogenated castor oil 3%, lecithin 2%, the dissolution process is to put the above composition in a water bath furnace ...

Embodiment 2

[0030] Weight percent of glass-ceramics: Bi 2 o 3 69%, SiO 2 9%, Al 2 o 3 8%, ZnO2%, B 2 o 3 10%, CuO3%, Ni 2 o 3 5%; organic binder weight ratio and dissolution process: terpineol 77%, tributyl citrate 12%, alcohol ester twelve 4%, ethyl cellulose 2%, hydrogenated castor oil 2%, lecithin 3%, the dissolution process is that the dissolution process is to mix, stir and dissolve each composition of the above-mentioned organic binder in a water bath furnace at a temperature of 90 ° C, and keep it warm for 4 hours. Slurry mixing process, the above-mentioned prepared glass-ceramic powder, silver powder and organic binder are placed in a container in a weight ratio of 51%: 30%:: 19% and stirred to prepare a slurry pre-product, and then pass through three times. The finished resistance slurry is rolled by rolling mill, and the solid content of the obtained resistance slurry is 81%.

[0031] square resistance resolution TCR / ppm / ℃ Aging strength 30±2mΩ / □ ...

example 3

[0034] Weight ratio of glass-ceramics: Bi 2 o 3 78%, SiO 2 3%, Al 2 o 3 5%, ZnO3%, B 2 o 3 7%, CuO5%, Ni 2 o 3 8%; organic binder weight ratio and dissolution process: 84% terpineol, 9% tributyl citrate, 2% alcohol ester twelve, 3% ethyl cellulose, 1% hydrogenated castor oil, lecithin 1%, the dissolution process is that the dissolution process is to mix, stir and dissolve each composition of the above-mentioned organic binder in a water bath furnace at a temperature of 85 ° C, and keep it warm for 4 hours. Slurry mixing process, the glass-ceramic powder, silver powder and organic binder prepared above are placed in a container according to the weight ratio of 487%: 377%: 157%, and then stirred to prepare a slurry pre-product, which is then passed through three rolls. The finished resistance slurry is obtained by rolling in a rolling mill, and the solid content of the obtained resistance slurry is 85%.

[0035] square resistance resolution TCR / ppm / ℃ Agi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com