Paste taking components and packaging

A paste and component technology, which is applied in the field of paste access components and packaging, can solve the problems of tilting and warping of the access cover, reduce the chance of bacterial contamination, and ensure reliability and sustainability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

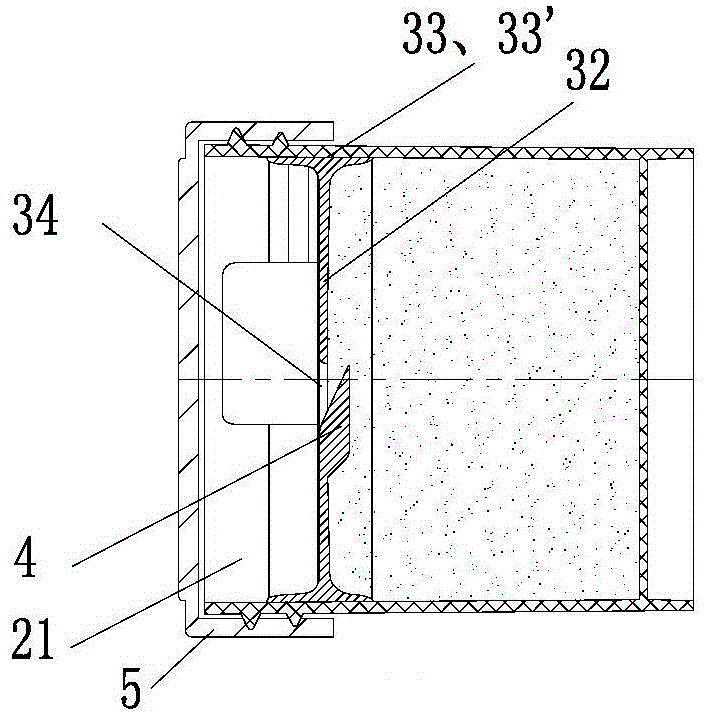

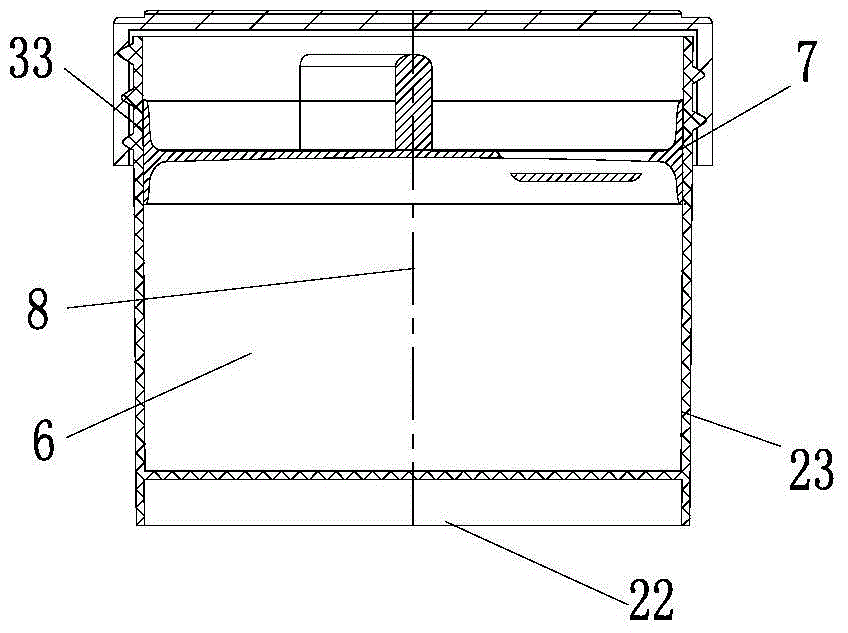

[0052] like figure 1 , 4 As shown, the paste taking package of this embodiment includes a paste taking assembly 1 , a container 2 , and a top cover 5 , and the top cover 5 is detachably connected to the container opening 21 of the container 2 .

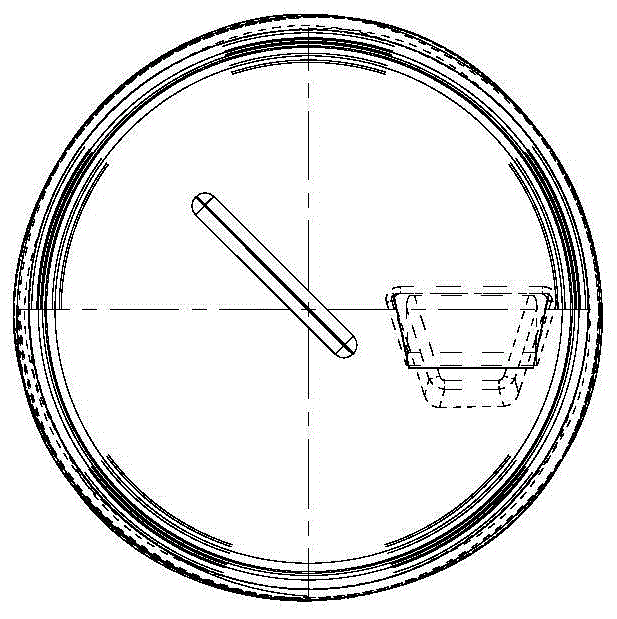

[0053] like figure 2 , 3 As shown in , 6 and 9, the paste taking assembly 1 includes a taking cover 3 that can be attached to the paste 6, and the taking cover 3 is embodied as a rotating cover 3 in this example. The rotating cover 3 has a lower surface 32 to which the paste 6 can be attached, an upper surface 31 opposite to the upper surface 31 , and an outer peripheral surface 33 connecting the upper surface 31 and the lower surface 32 . An access opening 34 is formed through the upper surface 31 and the lower surface 32 , and a blade 4 is located under the access opening 34 . The blade 4 is integrally formed with the rotating cover 3 . The spatula 4 has a spade surface facing the access cover 3 and used to guide the paste 6 ...

Embodiment 2

[0067] like Figure 25-33 As shown, the difference between the paste taking package of this embodiment and the first embodiment is that the restricting structure 7 is realized by arranging three pillars on the rigid frame 9, and the outer edge of the rigid frame 9 is provided with a thinner The soft elastic body 13, the column and the soft elastic body 13 are in contact with the inner wall 23 of the container to form a side contact surface 33'. The side contact surface 33' in the first embodiment is a continuous and regular strip, while the side contact surface 33' in this embodiment is irregular.

[0068] After the cover 3 is taken and loaded into the container 2, the soft elastic body 13 and its lower elastic thin-walled eaves-like structure 37 are radially deformed due to the extrusion of the inner wall 23 of the container, and press the inner wall 23 of the container outward, thereby The paste 6 is sealed in the container 2 .

[0069] The pillars and the hard frame 9 ens...

Embodiment 3

[0072] like Figure 34-39As shown, the difference between the paste taking package of this embodiment and the first embodiment is that the restricting structure 7 of this embodiment extends downward along the vertical direction at the outer edge of the taking cover 3, so that the cross section of the rotating cover 3 is outside the The outline is in the shape of "П", and the restricting structure 7 in this example is realized by an intermittent rigid frame 9' and a soft elastic body 13. The intermittent rigid frame 9' is an elastic structure that pops out to the outside and It is wrapped by a continuous thin soft elastic body 13 . The advantage of this arrangement is that the skeleton is a hard material, which can keep the basic function of the restricting structure 7 . At the same time, the rigid skeleton 9 ′ has a certain elasticity, can be deformed to a certain extent, and can better adapt to the slope of the inner wall 23 of the container. change, and the thinner soft ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com