Byssus removing machine for mussel

A silk and silk machine technology, which is applied in the field of mussel silk removing machine, can solve the problems of low production efficiency and high labor intensity, and achieve the effects of improving production efficiency, good effect, and improving gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

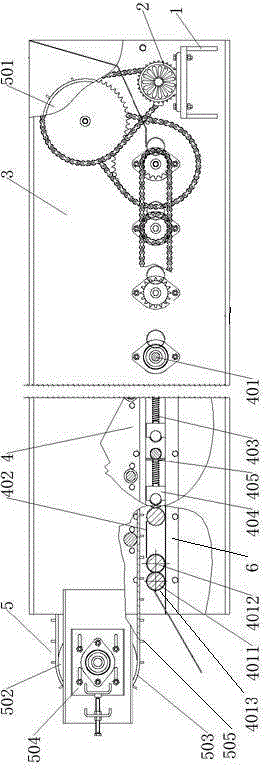

[0013] Such as figure 1 As shown, a mussel shredder removing machine includes a frame 6, a motor 2, a shredder removing device 4, and a material shifting device 5.

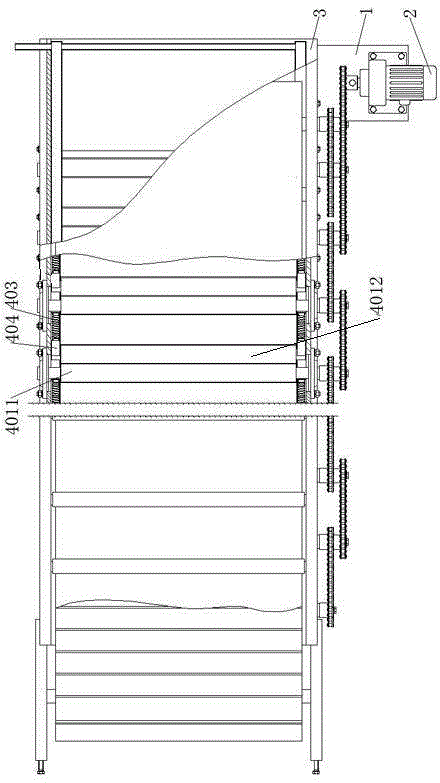

[0014] Such as figure 1 , figure 2 As shown, there are support plates 3 on both sides of the frame 6 respectively, and the motor 2 is assembled on the outside of a support plate 3 via a motor base 1.

[0015] in figure 1 Among them, the foot-removing device 4 includes several pairs of foot-removing rollers 401.

[0016] Such as figure 1 , figure 2 As shown, each pair of thread-removing rollers 401 is composed of a driving roller 4011 and a driven roller 4012.

[0017] In order to improve the gripping force of the thread removing roller on the mussel thread, such as figure 2 As shown, knurling 4013 is provided on the circumferential surfaces of the driving roller 4011 and the driven roller 4012.

[0018] in figure 1 , figure 2 Each of the driving rollers 4011 is rotatably supported between the two supporting plates 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com