A kind of preparation method of black tea leaves

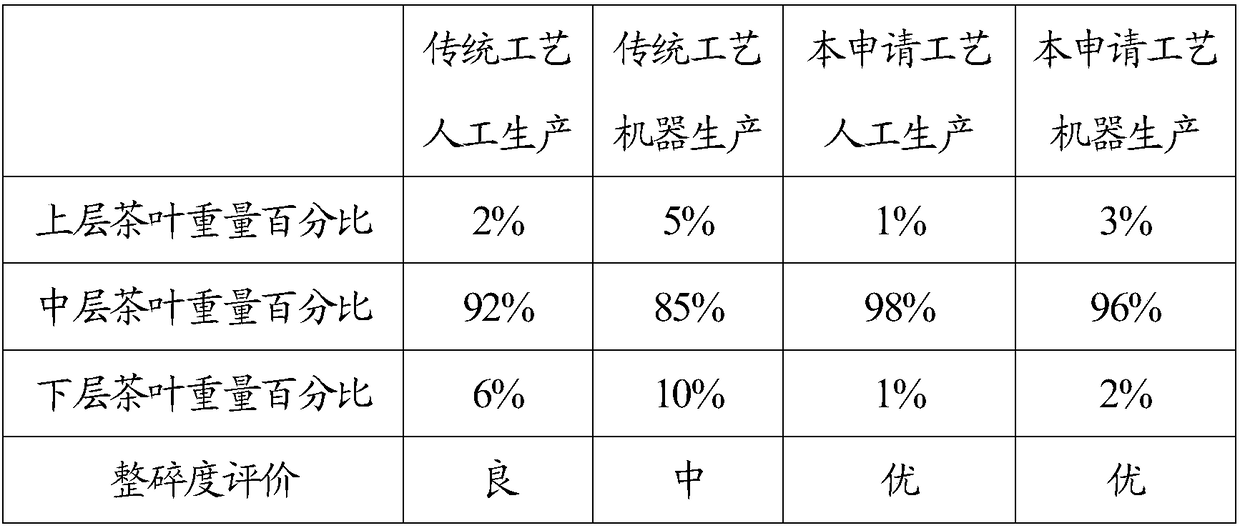

A technology for tea and black tea, applied in the field of preparation of black tea tea leaves, can solve the problems of high degree of brokenness, low degree of brokenness, and difficulty in controlling the degree of lightness and severity of machines, and achieves the effect of good degree of wholeness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of black tea leaves, comprising the following steps:

[0021] 1) Withering: Put the tea leaves on the drying cloth and place them in the sun for withering. The best temperature is 30°C-35°C. During the withering process, turn them lightly 2 to 3 times depending on the water dissipation of the tea leaves. Evenly heated, the time is generally 20-30 minutes, extended to 30-60 minutes when the sun is slightly hot;

[0022] 2) Dry green: Dry green at a temperature of 30°C-32°C, so that the taste changes from chlorophyll green to fruity green, with a floral scent; the leaves are soft and the heart leaves are a little drooping, and the hand feels a little elastic ;

[0023] 3) Greening: Greening is carried out at a temperature of 18°C-24°C, the number of greening is 3-5 times, and the standing time is 1-2 hours each time; the last greening lasts about 3-20 hours. Minutes, let it stand for 3-5 hours, so that the tea leaves have no grassy smell;

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com