Method for producing cake through 3D printing

A 3D printing, cake technology, applied in the application, food forming, food science and other directions, can solve the problems of troublesome production, large size, complex shape, etc., to solve the difficulty of realization and liberate the effect of physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

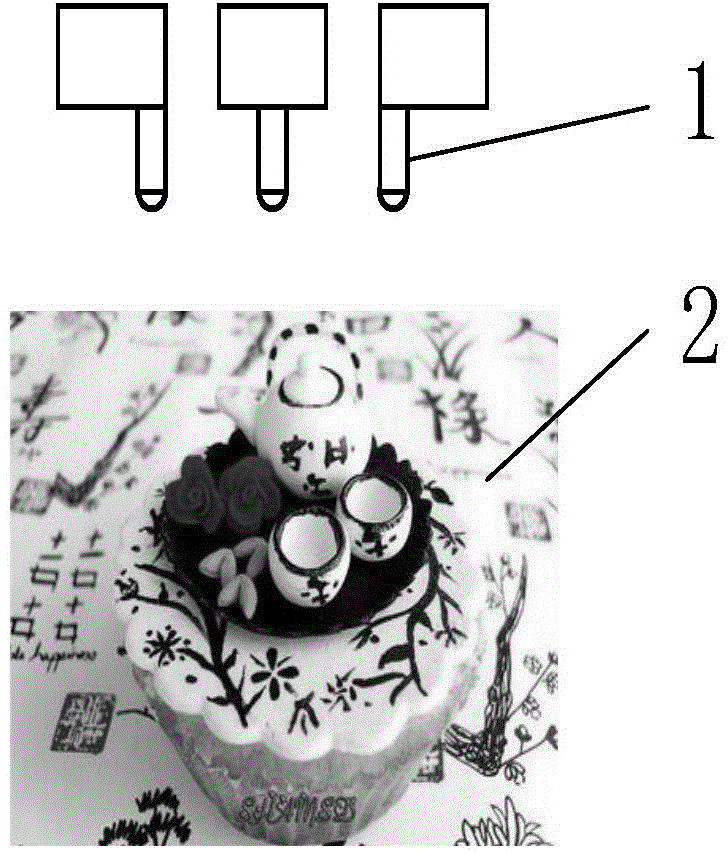

Image

Examples

Embodiment Construction

[0015] In order to better illustrate the present invention and facilitate understanding of the technical solutions of the present invention, typical but non-limiting examples of the present invention are as follows.

[0016] The raw materials for producing cakes and other raw materials such as cream and chocolate for decoration and beautification are loaded into different 3D printing heads.

[0017] When it is necessary to produce a custom cake, the shape and pattern are designed according to the customer's requirements and input into the 3D printer.

[0018] Through the 3D printing head, the final shape of the cake and the decoration patterns on the cake surface that meet the requirements are directly produced by printing.

[0019] The applicant declares that the above content is a further detailed description of the present invention in conjunction with specific preferred embodiments, and it cannot be assumed that the specific implementation of the present invention is limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com