Organic solvent rinsing tower

An organic solvent and leaching technology, which is applied in the field of leaching towers, can solve the problems of single dust removal means, poor dust removal effect, and poor cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

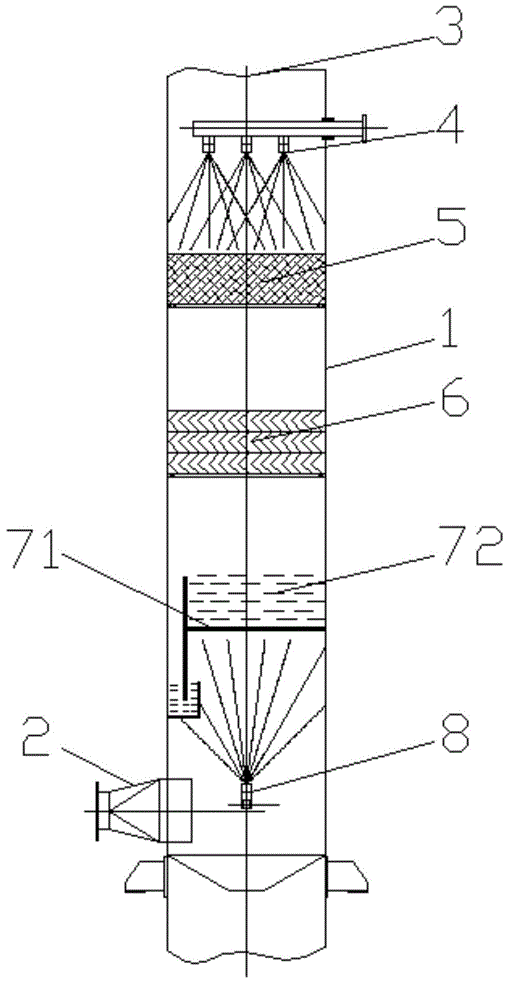

[0019] according to figure 1 , the present invention provides an organic solvent elution tower, comprising a cylindrical leaching tower shell (1), an air inlet (2) is opened on the bottom side wall of the leaching tower shell, and an air outlet (2) is provided on the top ( 3), the opening of the air inlet faces the tangential direction of the inner wall of the elution tower shell, and between the air outlet and the air inlet, there are three upper nozzles (4), a filling layer (5), and three nozzles from top to bottom. A baffle (6), a bubbling dedusting mechanism and a lower nozzle (8) are arranged staggered up and down.

[0020] Among them, the thickness of the filling layer is 20 cm, and the filling is in the form of thin strips or granules to ensure a large contact surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com