A kind of degradable hollow fiber membrane and preparation method thereof

A fiber membrane and hollow technology, which is applied in the field of degradable hollow fiber membrane and its preparation, can solve the problems such as the difficulty of degrading the hollow fiber membrane, and achieve the effect of good water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

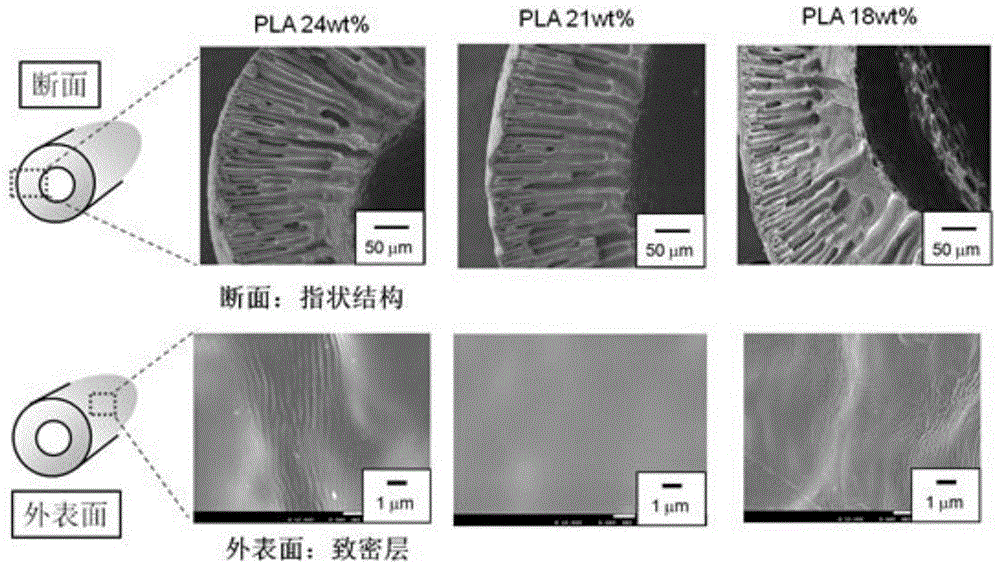

[0025] Heat 24% polylactic acid, 4% PEG-PLA-PEG, 2% PEG20000 and 70% DMSO at 140°C to form a homogeneous solution by weight percentage, and stir for 2 hours to form a casting solution; slow down the stirring speed and Degas at 95℃ for 1 hour; under certain pressure, the casting liquid passes through the spinneret. The spinneret consists of an outer tube and an inner tube. The casting liquid and inner liquid are sent into the spinneret separately at 95℃ The outside and inside of the tube are extruded from the spinneret and introduced into a 4°C low-temperature ice water bath to induce phase separation and solidify into hollow fibers; the prepared hollow fibers are immersed in circulating water to remove the solvent and internal liquid.

Embodiment 2

[0027] Heat 21% polylactic acid, 4% PEG-PLA-PEG, 2% PEG20000 and 73% DMSO at 130°C to form a homogeneous solution by weight, and stir for 2 hours to form a casting solution; slow down the stirring speed and set it at 100 Degassing at ℃ for 1 hour; under a certain pressure, the casting liquid passes through the spinneret. The spinneret consists of an outer tube and an inner tube. The hollow fiber membrane casting liquid and the inner liquid are sent to the spinneret respectively at 100°C The outer and inner sides of the fiber are extruded from the spinneret and introduced into a 5°C low-temperature ice water bath to induce phase separation and solidify into hollow fibers. The prepared hollow fiber is immersed in circulating water to remove the solvent and internal liquid.

Embodiment 3

[0029] Heat 18% polylactic acid, 4% PEG-PLA-PEG, 2% PEG20000 and 76% DMSO at 150°C to form a homogeneous solution by weight, and stir for 2 hours to form a casting solution; slow down the stirring speed and set it at 90 Degassing at ℃ for 1 hour; under certain pressure, the casting liquid passes through the spinneret. The spinneret consists of an outer tube and an inner tube. The casting liquid and inner liquid are sent to the outside of the spinneret at 90°C. And the inner side, extruded from the spinneret, and introduced into a 3°C low-temperature ice water bath to induce phase separation and solidify into hollow fibers; the prepared hollow fibers are immersed in circulating water to remove the solvent and internal liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com