Rock crusher

A pulverizer and rock technology, which is applied in grain processing and other directions, can solve the problems of inability to crush rocks, influence on accuracy and reliability, and low precision of test piece preparation, so as to ensure the operation of equipment and ensure the reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

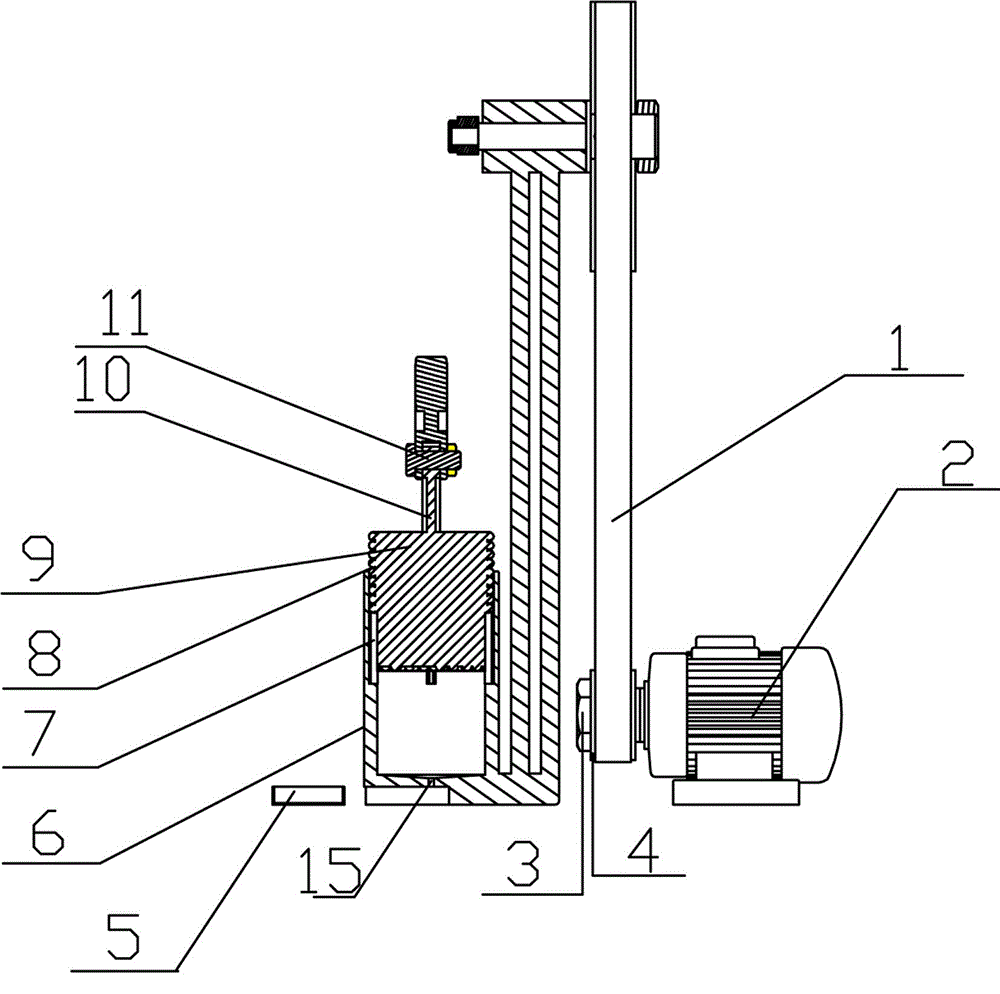

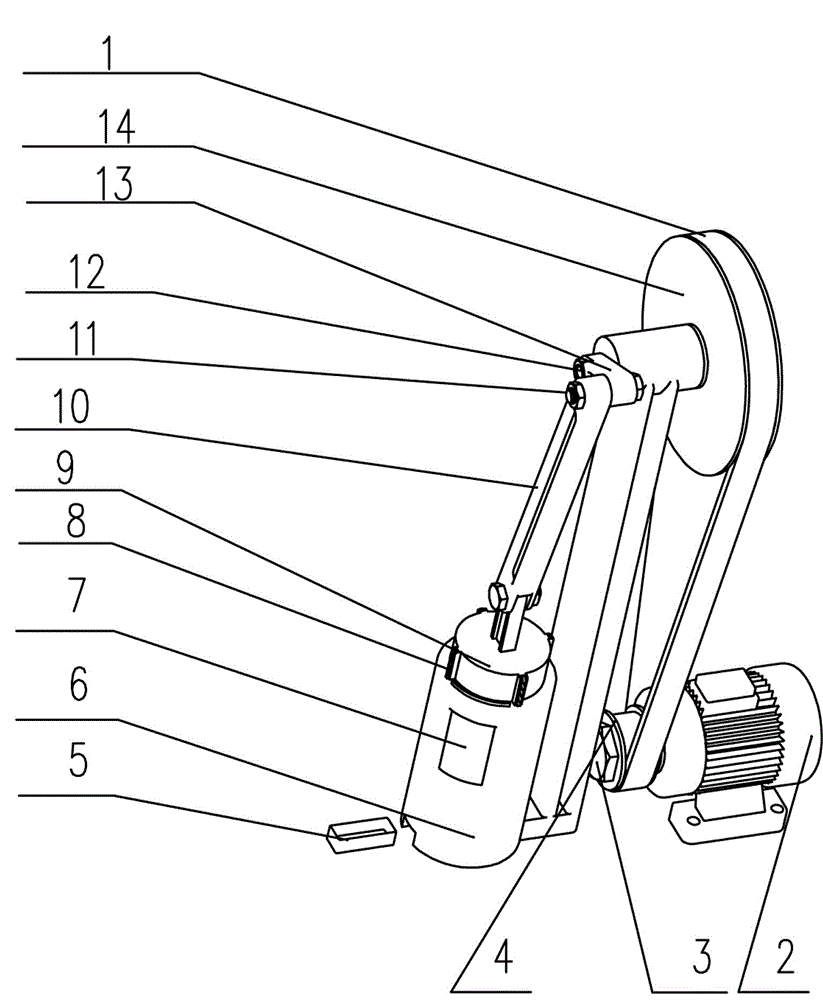

[0012] The structure of the present invention is as figure 1 -2 shows: a rock crusher, including a servo motor 2, the output shaft of the servo motor 2 is a small pulley shaft 3, the small pulley 4 is matched with the small pulley shaft 3, the large pulley 14 and the small pulley 4 There is a belt 1 in between, the large pulley 14 is connected to the large pulley shaft 12, the large pulley shaft 12 is connected to the I-shaped connecting rod 10 through the I-shaped crank 13, and the I-shaped crank 13 and the I-shaped connecting rod 10 are connected to the shaft through the crank connecting rod. 11 is connected, the I-shaped connecting rod 10 is connected with the drum block 9 in the main machine 6 of the crusher, the drum bar 8 is installed around the drum block 9 and the drum bar 8 matches the pulley groove on the main machine 6, and the main machine 6 A circular small hole 15 is opened in the center of the inner bottom, and the small hole 15 penetrates to the bottom groove, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com