Foundry molding sand processing and feeding device

A technology for casting molds and loading racks, which is applied in the field of molding sand feeding devices and casting molding sand processing feeding devices, which can solve the problems of high collapsibility and poor quality of molding sand, and achieve the effect of improving molding quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

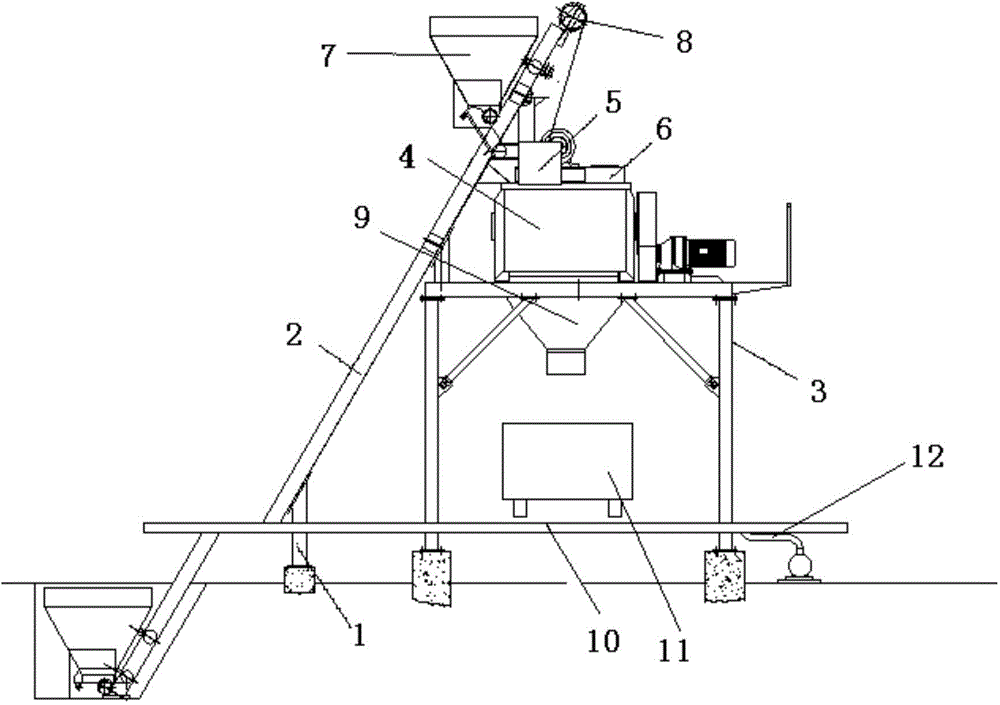

[0010] See the accompanying drawings; a feeding device for foundry molding sand processing, including a leg 1 and a feeding rack 2, a feeding rack 2 is fixedly installed on the leg 1, and a chassis 3 is provided on one side of the feeding rack 2 , a mixer 4 is fixedly installed on the chassis 3, an additive addition port 5 and a feed inlet 6 are provided on the side wall of the mixer 4, a hopper 7 is slidably installed on the loading rack 2, and the hopper 7 is fixed by The motor 8 installed on the upper end of the feeding rack drives to realize moving up and down.

[0011] The lower end of the mixer 4 is provided with a hopper 9, and a conveying guide rail 10 is arranged below the hopper 9, and a conveying trolley 11 slides on the conveying guide rail 10.

[0012] The side wall of the mixer 4 is provided with a water supply pipe 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com