Multipurpose adjustable busbar welding support assembly

A technology of welding bracket and adjusting mother, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficulty in welding work, difficult alignment of interfaces, unevenness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

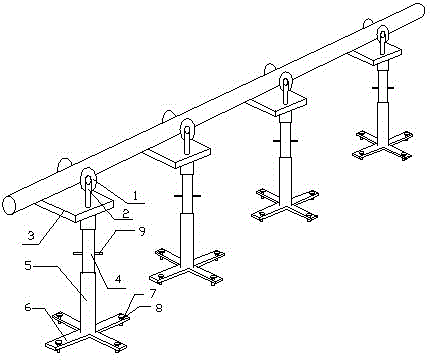

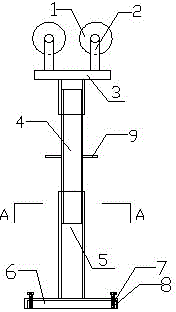

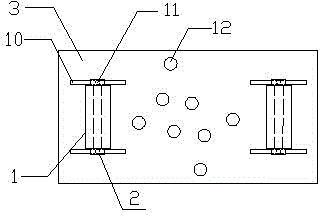

[0020] Such as Figure 1 to Figure 3 As shown, this embodiment is used to support the welding of tubular bus bars, and includes a plurality of support units, each support unit includes a support plate 3, an adjustment pipe fitting 4, a pillar 5 and a base 6, and support frames 2 are provided on both sides of the support plate 3 , the support frame 2 is inverted U-shaped, including both side struts and crossbeams, movable rollers 1 are fixed on the support frame 2 crossbeams, and the support plate 3 is provided with a certain length of The chute 10, the bottom of the struts on both sides of the support frame 2 are provided with screw holes 11. During use, the screws pass through the chute 10 and cooperate with the strut screw holes 11 to fix the support frame 2 on the support plate 3. At this time, the round head of the screw The diameter needs to be greater than the width of the chute 10. During welding, the tubular busbar can be erected on the movable roller 1, and the tubul...

Embodiment 2

[0023] Such as Figure 4 to Figure 6 As shown, this embodiment is used to support the welding of rectangular busbars, and includes a plurality of support units, and each support unit includes a support plate 3 , an adjusting pipe 4 , a pillar 5 and a base 6 . The difference with Embodiment 1 is that in this embodiment, the support frame 2 is not installed on the support plate 3, but a plurality of pin holes 12 are provided on the width direction of the support plate 3. For rectangular busbars of different widths, welding When inserting the pin 13 in the two pin holes 12 whose spacing is the same as the width of the bus bar, then the rectangular bus bar is fixed between the two pins 13 .

[0024] The working principle of the present invention is: when a plurality of tubular busbars need to be welded on site, firstly connect the support plates 3, adjusting pipe fittings 4 and pillars 5 of each support unit in sequence, and then according to the diameter of the tubular busbars to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com