2400mm wide aluminum plate cross cutting unit

An aluminum plate, cross-cutting technology, applied in other manufacturing equipment/tools, sending objects, manufacturing tools, etc., can solve the problems of increasing the operating cost of enterprises, rarely producing ultra-wide aluminum plates, affecting the development of enterprises, etc. The effect of a wide range of rulers and easy promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

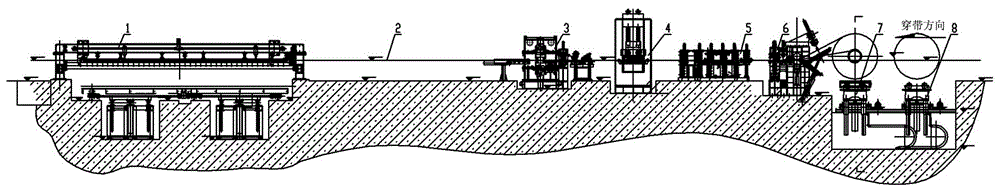

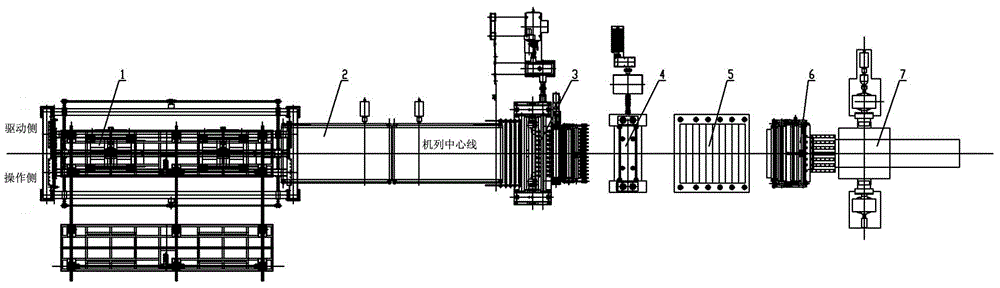

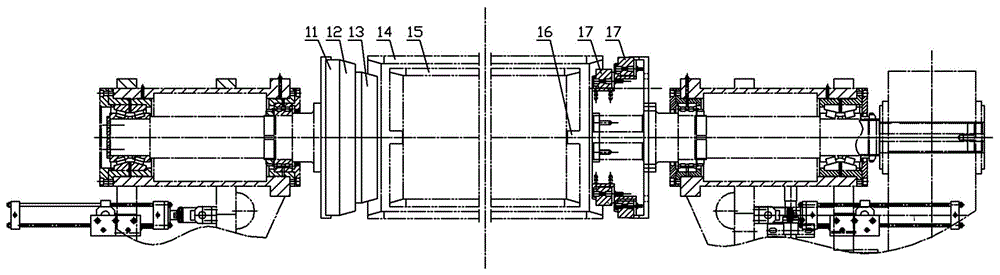

[0029] Example: see figure 1 , figure 2 and image 3 , in the figure, 1-stacking machine, 2-conveyor, 3-flying shear, 4-straightening machine, 5-cleaning machine, 6-cutting head shear, 7-uncoiler, 8-loading car, 11 -conical head body, 12-large conical truncated, 13-small conical truncated, 14-big sleeve, 15-small sleeve, 16-locating groove, 17-locating block.

[0030] The 2400mm wide aluminum plate cross-cutting unit, from the uncoiling of the aluminum plate to the stacking plate, successively passes through the uncoiler 7, the cutting head shear 6, the cleaning machine 5, the straightening machine 4, the flying shear 3 and the stacking machine 1, among which, the cutting head shear 6 The feed end is provided with pinch rollers, a conveyor 2 is provided between the flying shear 3 and the palletizer 1, the palletizer 1 is provided with a pneumatic automatic opening and closing mechanism, and a pallet truck is provided below the palletizer 1 .

[0031] The lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com