Composite plywood

A technology of plywood and plywood, which is used in the joining of wooden veneers, wood processing appliances, layered products, etc. Improve pressure and impact resistance, high pressure and impact resistance, prevent cracking or breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

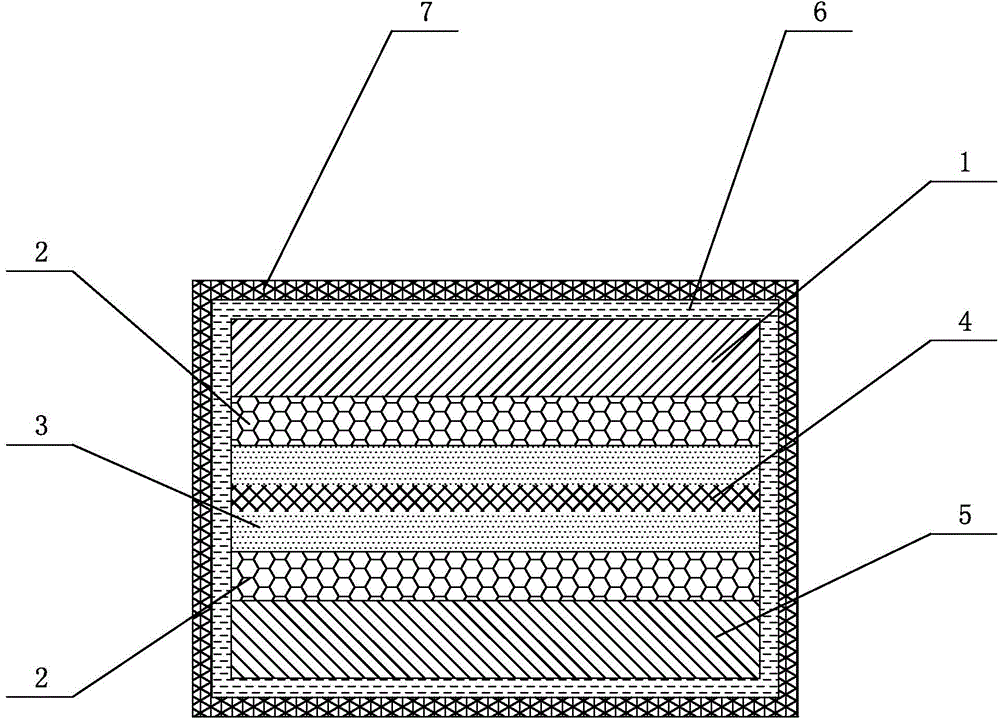

[0020] Such as figure 1 As shown, a specific embodiment of the present invention is proposed, a composite plywood, including a board body, and the board body includes a panel 1, a core board 3, a bottom board 5 and a glued layer 2 between each ply board, and this example is preferably The structure of the plywood layer 2 is set as a honeycomb hollow or grid structure, so that the plywood has sound insulation performance.

[0021] Both the panel 1 and the bottom plate 5 are hot-pressed high-density veneers. In this example, it is preferable to set a layer of metal mesh 4 in the middle of the core plate 3, so that the plywood has good pressure bearing and impact resistance.

[0022] The glued layer 2 is made of polypropylene resin and expanded vermiculite powder. In this embodiment, expanded vermiculite powder with a particle size of ≤74um is preferably used to make the plywood have more excellent flame retardancy.

[0023] The board body is surrounded by a layer of insect-proo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com