Adjustable magnetic block magnetic support rotating ultrasonic tool holder

一种旋转超声、可调式的技术,应用在石材加工工具、精细的工作装置、工作配件等方向,能够解决稳定性差、径向刚度低、加工精度降低等问题,达到提高稳定性、提高径向刚度、提高加工精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

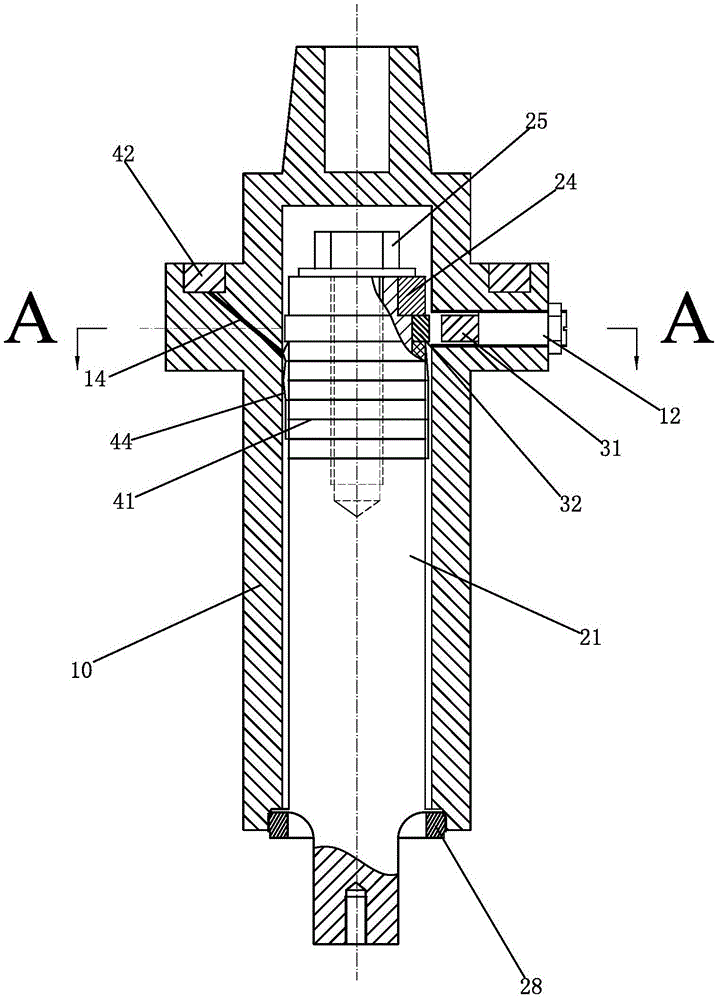

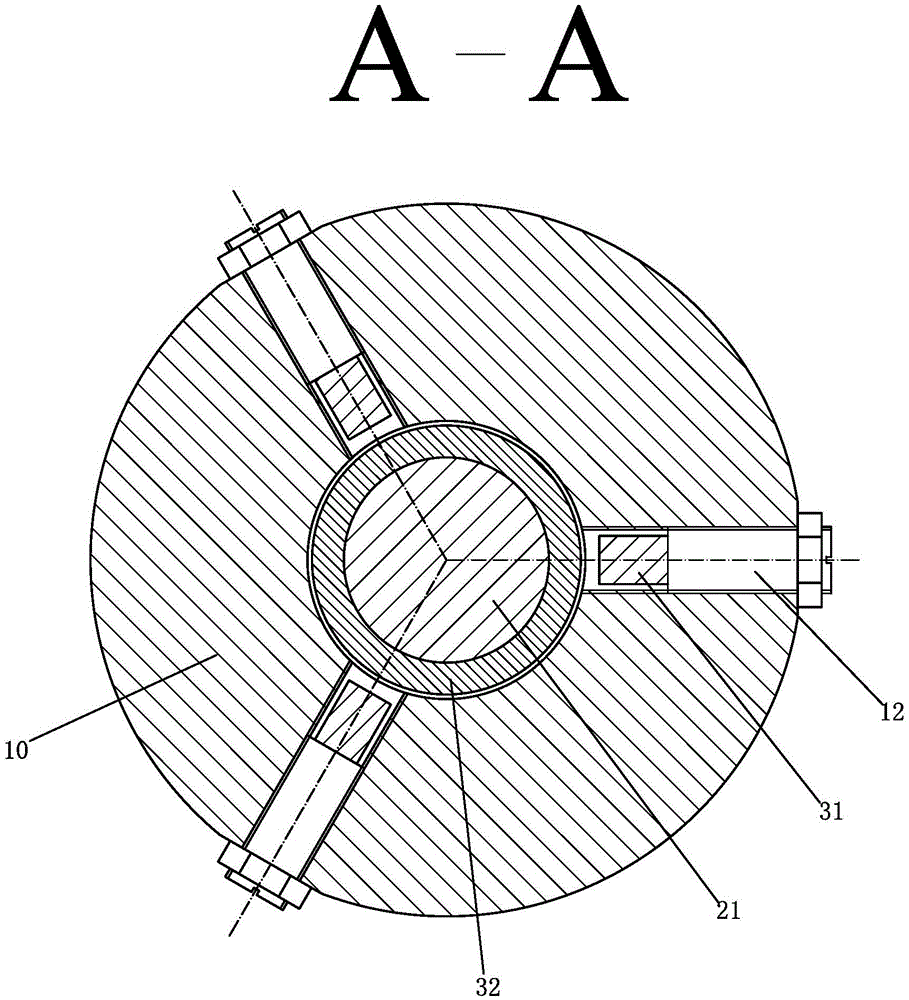

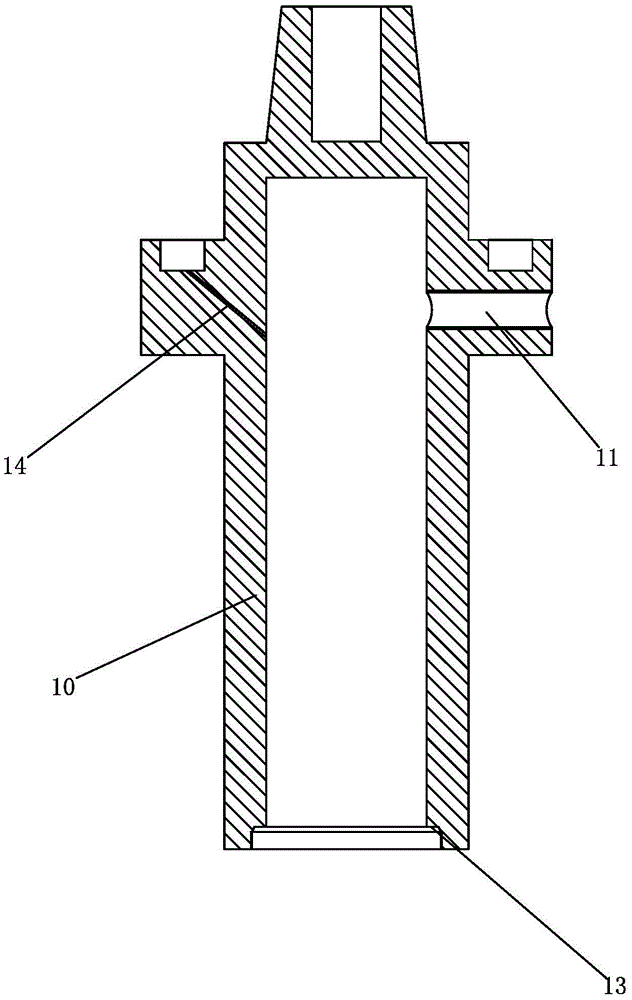

[0019] Please check Figure 1 to Figure 4 , a preferred embodiment of an adjustable magnetic block magnetically supported rotating ultrasonic handle, the adjustable magnetic block magnetically supported rotating ultrasonic handle includes a machine tool, a handle housing 10, an ultrasonic system, and several block magnets 31 And ring magnet 32.

[0020] The tool handle housing 10 is rotatably mounted on the machine tool.

[0021] In this embodiment, the handle housing 10 is provided with a plurality of first threaded holes 11 penetrating through the inside and outside of the handle case 10 and arranged at intervals in a ring. The inner ends of the first threaded holes 11 correspond to the ring magnets 32 . In this embodiment, the number of the first screw holes 11 is set to three, and in practical applications, the number of screw holes can also be changed according to actual processing needs, and a corresponding number of block magnets 31 can be provided.

[0022] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com