Unpowered bogie for 100-percent low-floor light rail vehicle

A power bogie and low-floor technology, applied in the field of rail vehicles, can solve the problems of low bearing capacity, poor maintenance, and fast tread wear, and achieve the effects of improving bearing capacity, easy maintenance, and prolonging service time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

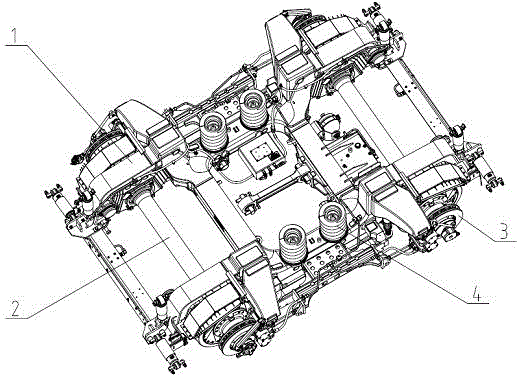

[0026] refer to figure 1 , The bogie of the present invention is generally assembled by a frame device 1, a wheel-to-axle box positioning device 2, a foundation braking device 3, and a secondary suspension device 4. The frame device 1 is the main structure of the bogie, and other components are assembled on the frame device through bolt connection.

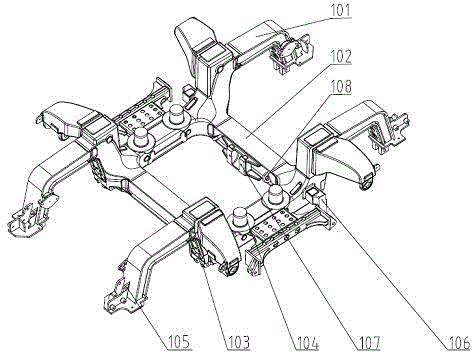

[0027] refer to figure 2 , the frame device 1 is generally welded by two side beam structures 101 and two beam structures 102. In the side beam structure 101, a series of spring mounting seats 103 and a secondary spring mounting seat 104 are designed according to functional requirements. The two mounts are a composite casting integrated structure, and their respective functions are obtained through secondary overall processing; at the end of the side beam structure 101, there is a composite mount 105 for a secondary horizontal and vertical shock absorber, which is welded to the main structure Connection: A magnetic rail stopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com