Electric car frame structure for distributed installation of battery packs

A technology of electric vehicle and frame structure, which is applied in the substructure, electric power unit, transportation and packaging, etc., can solve the problem that the integrity and safety performance of battery cells cannot be guaranteed, the overall quality of the frame and battery pack structure is large, and it is difficult to Battery pack safety performance protection and other issues, achieve excellent machining performance and casting process performance, achieve lightweight design, and reduce natural phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

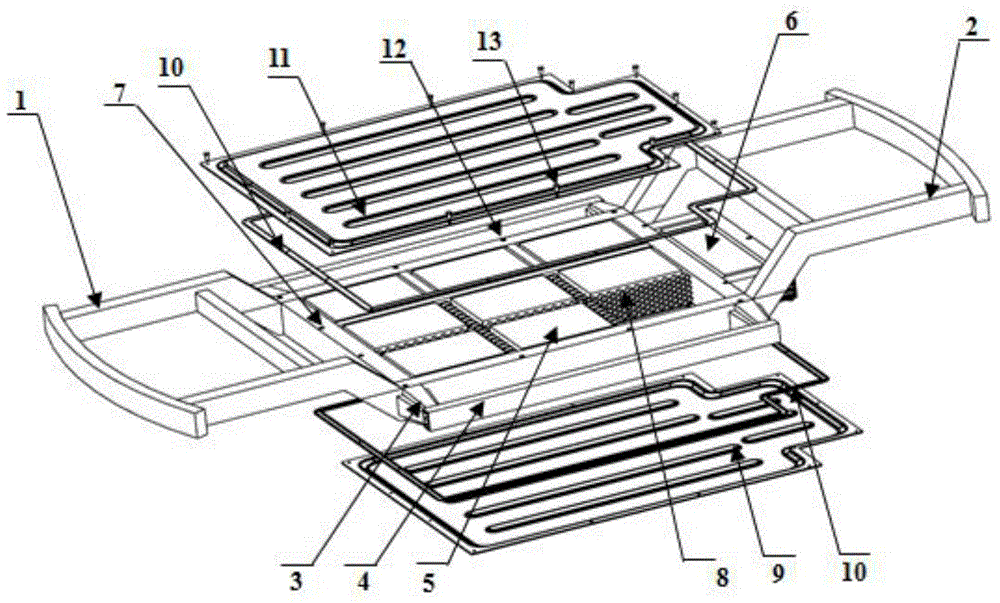

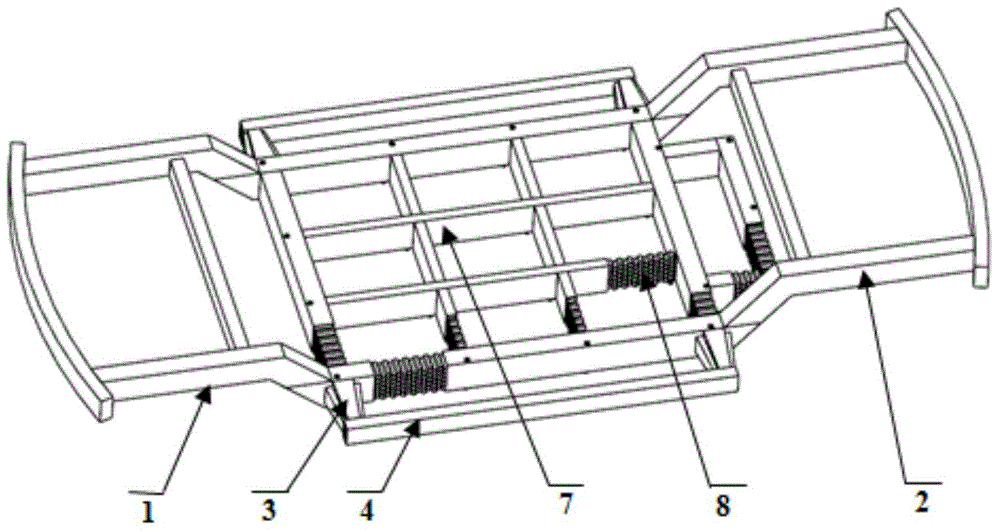

[0046] like Figure 1-2 As shown, the electric vehicle frame structure for distributed installation of battery packs according to the present invention includes four parts: a frame type frame, a block type battery pack structure, a sealing plate and a floor.

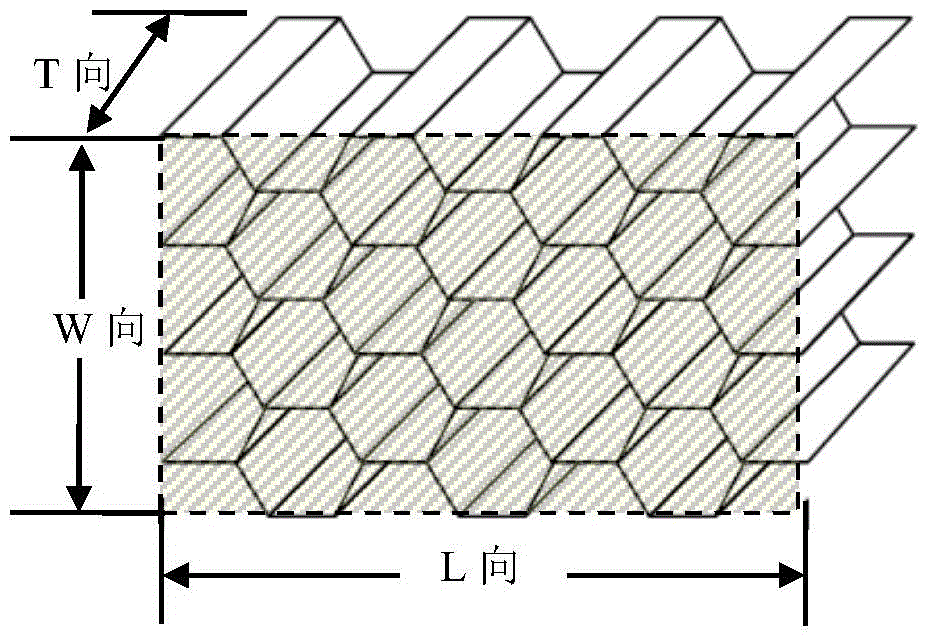

[0047] The framed frame includes a front beam 1, a rear beam 2, a tapered multicellular thin-walled tube structure 3 and a sill structure 4; wherein, the front frame 1 is located at the front end of the framed frame, and the rear frame The frame 2 is located at the rear of the frame type frame, the front frame 1 and the rear frame 2 are connected through the longitudinal energy-absorbing structures located on the left and right sides of the orthogonal energy-absorbing structure 7, and the threshold structure 4 is connected with the orthogonal energy-absorbing structure 7. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com