Rotary wing blade type flapping wing air vehicle

A flapping wing aircraft and rotary wing technology, applied in the aviation field, can solve problems such as limited lift efficiency and poor movement continuity, and achieve the effect of strong maneuverability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

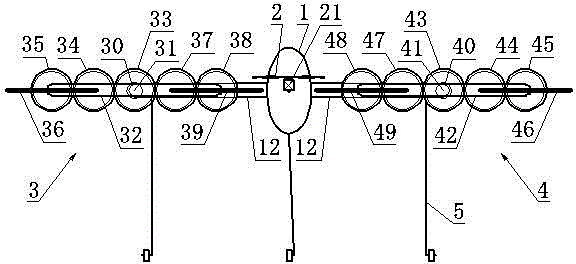

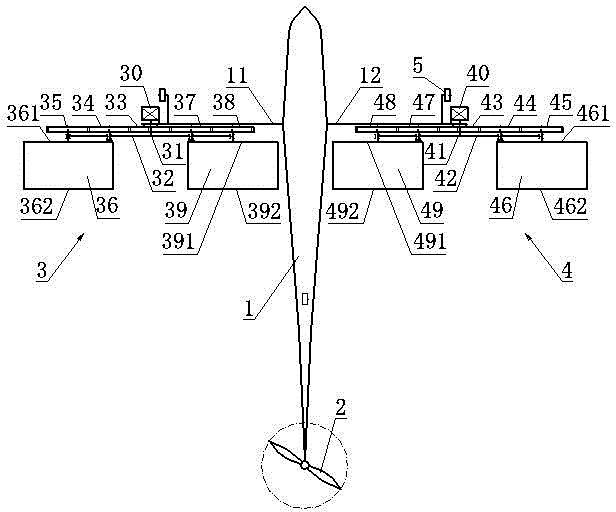

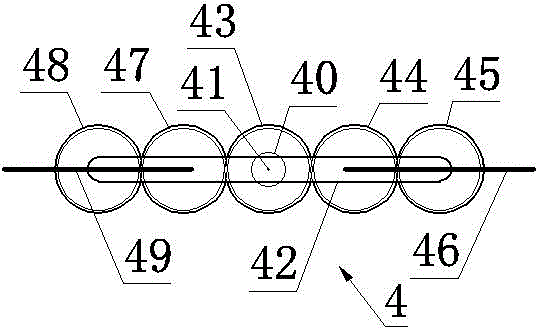

[0013] now attached Figure 1~5 The present invention is specifically described as follows: a flapping-wing aircraft with rotating blades mainly consists of a fuselage 1, a tail propeller 2, a left-rotating flapping-wing device 3, a right-rotating flapping-wing device 4, and an undercarriage 5. The fuselage 1 is equipped with a control system, an automatic navigation autonomous flight instrument and a remote control system. The aircraft adopts a combination of an automatic navigation autonomous flight mode and a remote control flight mode. Fly in autonomous flight mode. The left-rotating flapping-wing device 3 and the right-rotating flapping-wing device 4 have the same structure, parameters and working principle and are symmetrically arranged on the left and right brackets 11 and 12 protruding from the left and right sides of the fuselage 1 to generate lift. and thrust. The tail propeller 2 is driven by a small motor 21, and the rotation plane of the tail propeller 2 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com