Railway tank car used for transporting organic chemical raw materials

A technology for chemical raw materials and railways, applied in the direction of transporting passenger cars, railway car body parts, tank cars, etc., can solve the problems of waste of resources, unused functions, and underutilized functions of tank containers, avoiding waste and reducing costs. , the effect of prolonging the solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

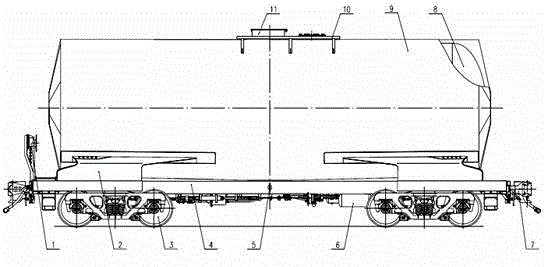

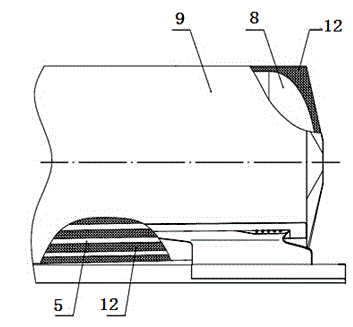

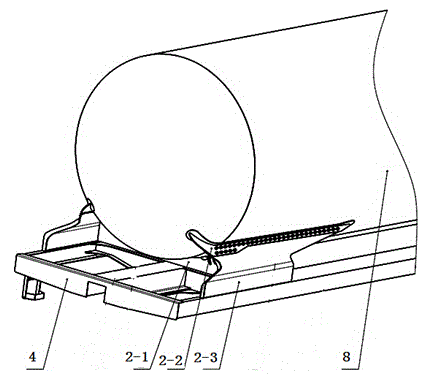

[0022] Such as figure 1 , 2 As shown, a railway tank car for transporting organic chemical raw materials of the present invention includes a frame and a tank body 8, and the frame is equipped with necessary hand brakes 1, bogies 3, wind brakes 6, couplers Buffer device 7, roof working platform 10, etc. A heating pipe 5 is welded on the outer wall of the tank body 8 , the tank body 8 and the heating pipe 5 are surrounded by an insulating layer 12 , and the insulating layer 12 is surrounded by a windshield 9 . The steam inlets of the heating pipes 5 are arranged on both sides of the car body, which can be heated by steam. When the medium in the tank body 8 is solidified, the purpose of dissolving the medium by heating the tank body 8 is achieved. The tank body 8 is covered by an insulation layer 12 that completely wraps the tank body 8 and the heating pipe 5. The ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com